6215R TRACTOR

Tractor

row-crop-6-family

- John Deere FT PowerTech™ 6-cylinder engines

- Engine HP: 237 HP Max 215/HP Rated with up to 40 additional HP (IPM)

- AutoQuad™, DirectDrive or IVT transmission options

- Optional CommandPRO™ puts tractor and implement control at your fingertips

Maintenance Plans

View Product Brochure

Features

Technology, connectivity, and automation

Operations Center

The John Deere Operations Center brings all your farm management data together in one place. Easy to understand, its integrated tools support your agronomic decision making and help you get maximum yield and consistent quality from your soil at significantly reduced input costs. Operations Center is how you turn valuable agronomic insights into smart decisions and easily define corrective actions. Other integrated tools let you create site-specific variable rate prescriptions and allow you to collaborate with agronomic advisors by granting them field-specific access rights. Documenting your work for clients also becomes a breeze with easily created, printed, and shared reports. What’s more, an Operations Center account is free to use no matter how big your operation is.

iTEC™ Pro

Intelligent Total Equipment Control integrates AutoTrac™ automatic steering and implement management systems to control tractor speed, front and rear mounted implements, and differential lock engagement, among other parameters. This allows for hands-free turns while reducing soil compaction, resulting in picture-perfect headlands and consistent crop growth.

JDLink™ system

See where your machines are and what they are doing with JDLink

See where your machines are and what they are doing with JDLink

JDLink shows where machines are, what they are doing, and how they are performing. You or your dealer can remotely assist operators with machine setup and operation leveraging Remote Display Access (RDA). JDLink connectivity additionally includes Wireless Data Transfer (WDT) for seamless data exchange between the machine and the office.

- Easily transfer data and collaborate with trusted advisors

- Better enable data-driven decisions

- Report work completed accurately and timely

- Increase machine uptime with Connected Support through remote monitoring services and diagnostics

- Get quick in-field support with RDA

- Remotely manage machines and employees to give you insights into how they are performing

Guidance solutions

AutoTrac ready

John Deere AutoTrac system provides a hands-free guidance solution, helping to manage in-field efficiency and greatly reducing operator fatigue. The 6R Tractor comes from the factory as AutoTrac ready, which includes the software, sensors and valves to provide an integrated solution for the producer (receiver and activation are purchased separately). This allows producers to capture the value of guidance without the installation of labor-intensive kits.

AutoTrac Turn Automation

AutoTrac Turn Automation controls the entire headland turn and manages all tractor and implement functions, including forward speed changes and power take-off (PTO) switching. It raises or lowers the hitch or activates selective control valves (SCVs) at exactly the right time and position in the field to guarantee perfectly consistent headland crop growth.

AutoPath™ system

AutoPath automatically creates guidance lines for different width machines based on data gathered by the first pass of a tillage implement or planter. It takes charge of your guidance line management, protecting nutrient investment and helping you make each pass with confidence and precision. If you are using different width implements for planting, spraying, or harvesting, AutoPath ensures the tires always follow the planted rows and stay off the crop. When harvesting, the combine is always guided to the correct starting point, and the guidance lines are automatically calculated based on the width of the header.

Operator station

View of cab

View of cab

Operator station

The 6R Tractor cab delivers on comfort and convenience, regardless of your application. The all-around visibility and easy-to-use controls make the 6R a perfect fit for your operation. All 6R Tractors include a corner post display featuring state-of-the-art electronic instrumentation that blends well with the narrow right-hand cab post. This provides all the critical machine information and enhanced visibility. In addition, premium features such as automatic climate control, an instructor seat, and foot throttle come standard on the 6R Tractors.

CommandARM™ controls and Generation 4 CommandCenter™ display

CommandARM and Generation 4 CommandCenter display

CommandARM and Generation 4 CommandCenter display

The CommandARM console provides a thoroughly intuitive operating interface. All the controls you need for daily work are available at your fingertips: selective control valves (SCVs), AutoTrac™ automatic steering, iTEC™ machine control, air conditioning, lights, radio, four-wheel drive (4WD), and hitch depth control. Mounted on the CommandARM, the Generation 4 CommandCenter display has easy-to-use, tablet- like swipe functionality and monitors everything you need for productive and efficient work.

CommandPRO™ control

CommandPRO joystick

CommandPRO joystick

The CommandPRO joystick combines a unique driving strategy with reconfigurable controls. All the controls you need for daily work are available at your fingertips: travel speed, acceleration response, reconfigurable buttons and rocker switches, and activation button.

Generation 4 CommandCenter display with Extended Monitor

Gen 4 Extended Monitor

Gen 4 Extended Monitor

The Gen 4 Extended Monitor doubles the screen area so you can monitor more functions at once and have direct access to make adjustments when needed. You could, for example, view vehicle control functions on your primary display and Precision Ag applications on the Extended Monitor.

Comfort and maneuverability

Operate the 6R Tractor with ease

Operate the 6R Tractor with ease

Operator Comfort

Triple-Link Suspension (TLS™)

TLS suspension

TLS suspension

The TLS Plus system provides optimal traction and field performance by maintaining ground-to-tire contact, enabling more power to the ground. It also ensures higher operator comfort, reduces operator fatigue, and increases productivity, while the Variable Ratio Steering improves in-field maneuverability.

Cab suspension

Cab suspension system

Cab suspension system

The intelligent hydropneumatic cab suspension offers more driving comfort in the field and on the road. Input from the acceleration and TLS sensor causes the cab suspension controller to increase or decrease the amount of oil in the shock absorber ram. This semi-active system delivers ultimate comfort in every situation.

Variable Ratio Steering

Variable Ratio Steering off

Variable Ratio Steering off

Variable Ratio Steering on

Variable Ratio Steering on

Variable Ratio Steering improves operator comfort, requiring less hand movement and less steering effort when turning on the headland or in confined spaces. This results in faster turning of the steering wheel and increases hydraulic flow, leading to a quicker response from the tires. The system can be activated or deactivated in the CommandCenter™ display and is available for all 6R Tractors.

Engine performance

Engine

The high power output of the John Deere 4-cylinder, 4.5L (274.6-cu in.) engine and the 6-cylinder, 6.8L (415-cu in.) engine is made possible by refined, four-valve, high-pressure common rail (HPCR) technology with an injection pressure of up to 2500 bar (36,259.4 psi). The PVS engine in the 6R 175, 6R 195, and 6R 215 models is equipped with a variable geometry turbocharger (VGT) that boosts performance and efficiency consistently across the torque curve. The PSS engines (6R 230 and 6R 250) use a two-stage turbocharging system in which the VGT multiplies the pressure created by a fixed vane turbocharger.

Intelligent Power Management (IPM)

Intelligent Power Management (IPM) is a feature for many typical farming operations that use the rear power take-off (PTO) in high-power applications or the tractor as a transport vehicle. Operators who are looking for more power in non-stationary PTO and transport applications will be interested in the IPM feature. In high rear PTO power applications such as forage harvesters, rototillers, and beet or potato harvesting equipment or where heavy trailers, carts, or implements are moved to and from various locations, this feature provides significant additional capabilities. The solution improves productivity with more consistent ground speeds, quicker acceleration, and the ability to better hold desired transport speeds. All 6R Tractors have IPM in base equipment. Hydraulic IPM is available as a separate option to enable the IPM in applications resulting in high hydraulic loads.

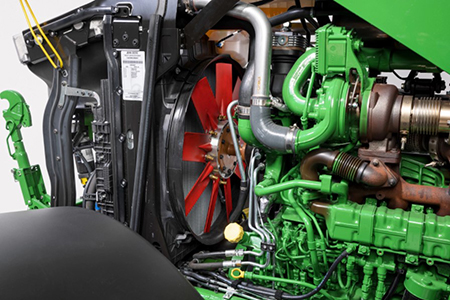

Reversible fan

Reversible fan

Reversible fan

Optimize engine performance in dusty environments by utilizing the optional reversible fan technology available on all 6R Tractors. The reversible fan allows the operator to quickly clean radiator screens from the comfort of the cab. By manually activating the system with a switch in the cab, the radiator fan blades blow out dust and debris away from the radiator. This enables the engine to run cooler, resulting in fuel savings, less downtime, and overall increased efficiency.

Hydraulics

Hydraulic system

Hydraulic system

The closed-center, pressure-and-flow-compensated hydraulic system in the 6R Tractors has been engineered for maximum durability and reliability by optimizing the number of hydraulic components and connections, which also makes it extremely efficient. The system in the 6R 230 and 6R 250 delivers a powerful 160 L/min (42.3 gpm) at 1500 rpm with enhanced operating characteristics. In a 6R Tractor, you get up to six electrohydraulic selective control valves (SCVs) with a pressure relief lever, logically clustered, and all iTEC™ capable. You can easily control flow rates and times from the cab with the CommandCenter™ display.

Hydraulic Intelligent Power Management (IPM)

As a supplement to power take-off (PTO) and transport applications, Intelligent Power Management also delivers additional horsepower for hydraulically driven implements. The Hydraulic IPM keeps tractor wheel speed constant during applications that use power-hungry hydraulically driven implements like slurry tankers, sprayers, or manure spreaders.

Transmission portfolio

AutoQuad™ transmission

6R Tractor

6R Tractor

The AutoQuad transmission has all the benefits of the PowrQuad™ PLUS transmission with the added convenience of automatic gear shifting. It is available in 20F/20R and 24F/24R versions. With the EcoShift option, a transport speed of 40 km/h (25 mph) is maintained at only 1533 rpm, reducing fuel consumption and emissions.

Enhanced AutoPowr™ transmission – Infinite speed adjustment in all situations

AutoPowr/IVT transmission

AutoPowr/IVT transmission

AutoPowr/IVT is a hydromechanical transmission that delivers stepless and continuous power at speeds between 40 km/h and 50 km/h (25 mph and 31 mph). The AutoPowr transmission maintains the selected speed by automatically responding to changing load conditions. Once running at maximum road speed, engine rpm automatically drops to the minimum level required to maintain that speed, thus reducing noise and saving fuel. A speed of 50 km/h (31 mph) is maintained at 1630 rpm, and a speed of 40 km/h (25 mph) is maintained at 1300 rpm with the CommandPRO™ joystick.

DirectDrive transmission – The benchmark for seamless efficiency

DirectDrive transmission

DirectDrive transmission

Specifically developed for 6R Tractors, DirectDrive is an eight-speed, three-range transmission designed and engineered by John Deere for heavy agricultural work. Super-efficient dual-clutch technology always has the next gear lined up, so there is no lost momentum during changes, fuel consumption is reduced, and ease of operation is assured. During transport, DirectDrive reduces the engine speed to 1550 rpm at 40 km/h (25 mph) and 1600 rpm at 50 km/h (31 mph), thus reducing fuel consumption. In addition, the AutoClutch function enables you to stop the tractor without pressing the clutch.

Loader application

R Series Loaders

John Deere R Series Front Loaders have automatic latch designs, making the installation of loader and implements very efficient. John Deere loaders are built for productivity with little maintenance required. When combined with the maneuverability and technology of the 6R Tractors, operators enjoy proficient material handling and feeding in any application. An optional technology package boosts your productivity thanks to Return-to-Position and further enhances precision with the Dynamic Weighing System while preventing material losses thanks to the electronic Level-to-Horizon feature.

Electronic control with reverser

Optional electronic control

Optional electronic control

Joystick on the CommandARM™ console

Joystick on the CommandARM™ console

John Deere 6R Tractors have an optional electronic control with an integrated reverser. The loader control has five reconfigurable buttons and rocker switch for tractor and ISOBUS functions.

Loader technology

Dynamic Weighing System

Enhance your precision on the go. The Dynamic Weighing System provides the operator with real-time weights that enable the operator to fill the loader to a desired weight. This delivers efficiency by reducing unnecessary trips to the feed source and allows operators to effectively manage the right combination of inputs into feed rations.

Return to Position

Boost your productivity for repetitive tasks. With Return-to-Position you can save up to four implement positions for quick and comfortable recall with the loader control.

Level to Horizon

Level-to-Horizon functionality

Level-to-Horizon functionality

Prevent material losses while keeping your speed with the Level-to-Horizon feature, which keeps the loader attachment level in uneven terrain.

Specifications

Compare the specifications of up to 4 models

| Key Specs | 6215r-tractor Current Model |

|---|---|

| Engine displacement | 6.8 L 415 cu in. |

| Rated engine power | 97/68EC: 158 kW 215 hp |

| Maximum engine power | 97/68EC: 174 kW 233 hp |

| Rated PTO power (hp SAE) | 130 kW 174 hp |

| Hydraulic pump rated output | Standard: 60 cc pump: 155 L/min 41 gpm |

| Rear hitch category (SAE designation) | Category 3/3N: 5440 kg 11,990 lb |

| Base machine weight | 8500 kg 18,739 lb |

| Engine specifications | |

| Engine type | Diesel, in-line, 6-cylinder, wet-sleeve cylinder liners with four valves in head |

| Engine family | NJDXL06.8324 |

| Rated speed | 2100 rpm |

| Aspiration | Turbocharged, fixed geometry first stage-variable geometry second stage, air-to-air aftercooling and cooled exhaust gas recirculation |

| Emission level | Final Tier 4 |

| After treatment type | DOC/DPF/SCR |

| Displacement | 6.8 L 415 cu in. |

| Engine performance | |

| Rated power | 97/68EC: 158 kW 215 hp |

| Rated PTO power (hp SAE) | 130 kW 174 hp |

| Intelligent Power Management (IPM) | Transport and/or mobile PTO applications Additional engine power (hp ISO) at 2100 rpm: 29.8 kW 40 hp |

| Power boost | 10 percent |

| Maximum engine power | 97/68EC: 174 kW 233 hp |

| Engine peak torque | At 1,600 rpm: 1004 Nm 740 lb-ft |

| PTO torque rise | 40 percent |

| Transmission | |

| Type | Standard: IVT, 0.05-42 km/h 0.03-26 mph Optional: IVT, 0.05-50 km/h 0.03-31 mph 24-speed AutoQuad PLUS ECO (40K) 24-speed AutoQuad PLUS ECO (50K) 24-speed Direct Drive (40K) 24-speed Direct Drive (50K) |

| Reverser | Left-hand electrical reverser |

| Hydraulic system | |

| Type | Closed-center, pressure-and-flow compensated |

| Pump rated output | Standard: 60 cc pump: 155 L/min 41 gpm |

| Available flow at a single rear SCV | 100 L/min 26.4 gpm |

| Number of rear selective control valves (SCVs) | Standard: Three ISO couplers Optional: Three to five ISO couplers |

| Number of mid selective control valves (SCVs) | Up to three |

| Joystick SCV control | Available |

| SCV control | Standard: Mechanical Optional: Electronic |

| Rear hitch | |

| Remote control valves available | Available: Remote control switch |

| Hitch category (SAE designation) | Category 3/3N: 5440 kg 11,990 lb |

| Maximum lift capacity behind lift points | 5450 kg 12,015 lb |

| Sensing type | Electrohydraulic |

| Rear axle differential lock | Electrohydraulic |

| Drawbar | |

| Drawbar category | Category 3 |

| Maximum vertical load | Category 3: 1600-2800 kg 3525-6170 lb Maximum vertical load dependent on drawbar position |

| Rear power take-off (PTO) | |

| Type | Independent Standard: 540E, 1000, 1000E rpm reversible shaft: 35 mm 1.375 in. Optional: 540, 540E, 1000 rpm reversible shaft: 35 mm 1.375 in. |

| Engine rpm (at rated PTO speeds) | 1950 engine rpm at 540/1000 rpm PTO 1761 engine rpm at 540E rpm PTO 1756 engine rpm at 1000E rpm PTO |

| PTO actuation | Electrical modulation |

| Front hitch | |

| Category | Category 3N |

| Electric power | Seven-pin electrical socket Optional: Three-pin and ISOBUS socket |

| Standard lift capacity | At hook ends: 3300 kg 7275 lb |

| Front power take-off (PTO) | 1000 rpm, clockwise rotation (from driving position) |

| PTO speed | Engine at PTO speed (1000): 1969 rpm |

| Rear axle | |

| Type | Standard:Rack and pinion, 2550 mm 100.4 in. Optional:Rack and pinion, 2806 mm 110.5 in. Rack and pinion, 3009 118.5 |

| Final drive type | Inboard planetary three pinion |

| Differential controls | Full-locking electrohydraulic |

| Front axle | |

| Front axle differential lock | MFWD: Limited slip TLS: Limited slip TLS with brakes: Full-locking electrohydraulic |

| Tires | |

| Rear | 480/80R42 R1/R1W Radial |

| Wheel tread range | MFWD: 1524-2235 mm 60-88 in. TLS: 1524-2235 mm 60-88 in. |

| Tracks | |

| Steering | |

| Type | Hydrostatic power |

| Brakes | |

| Electrical system | |

| Alternator size | Standard: 200 amp Optional: 250 amp |

| Battery options | 12 V |

| Working lights | Standard: 14 halogen Optional: 12 light-emitting diode (LED) plus two halogen |

| Type of bulb in headlight (Halogen, Zenon, LED) | Standard: 65-W halogen W Optional: LED |

| Total cold cranking amps | 1230 CCA With cold weather package or IVT: 1400 CCA |

| Operator station | |

| Seat | Degree of seat swivel, left hand CommandARM: 7.5 degree Degree of seat swivel, right hand CommandARM: 30 degree Standard: Air suspension Optional: Deluxe air suspension |

| Cab suspension | Optional: Adaptive Hydraulic Cab Suspension Plus (HCS Plus) |

| Instructional seat | Standard |

| Radio | Standard |

| Inner cab volume | 3.33 m3 117.59 cu ft |

| dB(A) rating | 71 dB |

| Cab glass area | 6.11 m2 65.77 sq ft |

| Dimensions | |

| Wheelbase | 2800 mm 110.2 in. |

| Overall width | 1892 mm 74.5 in. |

| Overall length | 5045 mm 198.6 in. |

| Overall height | 3160 mm 124.4 in. |

| Front axle center | 560 mm 22 in. |

| Approximate shipping weight, Open;Cab | 8500 kg 18,739 lb |

| Weight | |

| Base machine weight | Front axle 3400 kg 7495 lb Rear axle 5100 kg 11,243 lb Total MFWD, AutoQuad, front weight support, one pair 204-kg (450-lb) rear weights, front fenders, 480/80R46 rear duals, 420/90R30 front, shipping fuel: 8661 19,100 lb 8500 kg 18,739 lb |

| Maximum permissible weight | 13,450 kg 29,650 lb |

| Capacities | |

| Crankcase oil volume | 23.5 L 6.2 U.S. gal. |

| Fuel tank | 330 L 87.1 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | 20 L 5.3 U.S. gal. |

| Cooling system | 28 L 7.4 U.S. gal. |

| Transmission-hydraulic system | IVT: 75 L 19.8 U.S. gal. AutoQuad: 71 L 18.8 U.S. gal. DirectDrive ECO: 81 L 21.4 U.S. gal. |

| Serviceability | |

| Interval for engine oil change | 750 hours |

| Interval for hydraulic/transmission oil change | 1,000 hours |

| Interval for engine coolant change | 6,000 hours |

| Loaders | |

| Loader | 660R 680R |

| Lift capacity at full height | 660R: 2586 kg 5701 lb 680R: 2453 kg 5408 lb |

| Maximum lift height | 660R: 4520 mm 178 in. 680R: 4480 mm 176 in. |

| Precision AG | |

| Miscellaneous | |

| Country of manufacture | Germany |

Accessories and Attachments

Automation

Cab Equipment

Accessory Mounting Bracket - BL15042

Additional Inner Mirror for Hitch View - BL15087

Beverage Holder for Storage Net Holder - AL207633

Bottle-/ Cup-Holder - BL15522

Decal JD-Logo In Rear Window - AL208657

E-ICV Joystick, Command Arm - BL15368

E-ICV Joystick, Gearshift, Armrest (Grammer) Mounted - BL15916

E-ICV Joystick, Gearshift, Armrest (Sears) Mounted - BL15917

Field Office For Refrigerator - AL174265

Inner Rear View Mirror - BL16005

Lever (Multifunctional) SCV Position 3 and 4, GSS - BL15617

Monitor Bracket On C-Post - BL16101

Preparation For Tachograph - BL15141

Rear Window, Heatable - AL205891

Refrigerator - BL15028

Refrigerator with Field Office - BL15029

Sun Shade Front / Rear / Side - AL205893

Sun Visor - AL205892

Wiper Rear - BL15382

Cab Operator's Station

Tablet Mount Kit - BRE10255

Cold Start Packages

Cold Start Package - BL16189

Cold Start Package - BL16190

Cold Start Package - BL16191

Cold Start Package - BL16192

Cold Start Package - BL16193

Cold Start Package Preparation - BL16194

DEF-Tank Filler Neck Heater - BL15536

Fuel Heating Device - BL15539

Coupling Balls

Display

Bracket For Displays / Implements Controls - BL15157

Wiring Harness For Isobus Preparation (E.G. iTEC) - BL15586

Drawbar

Drawbar Dropdown, Cat. 2 - AL208071

Drawbar Dropdown, Cat. 3 - AL208070

Electrical Equipment

110V AC Power Outlet Socket, Single Phase - BL15805

Automatic Battery Cut-Off System - BL15402

Automatic Battery Cut-Off System - BL15993

Multiple Socket Strap With 7 Pin Signal Socket - BL15389

Multiple Socket Strap With 7 Pin Signal Socket Premium Plus - BL15391

Multipower Outlet - BL15392

Parts for Radar Sensor - AL204831

Power Outlet, C-Post, SAE - AL205868

Exhaust

Front Axle

Hub Extension 219mm, Front, Tread Adjustment - BL15107

Hub Extension 94mm, Front, Tread Adjustment - BL15106

Low Temperature Attachment For TLS - BL15180

Front Fenders

Front Hitch

Front Loader Equipment

Front Loader Preparation

EL. Midstack Valve, 2 FCT, Attachment For Comfort Front Hitch - BL15945

EL. Midstack Valve, 2 Function - BL15942

EL. Midstack Valve, 3 Function - BL15943

El. Midstack Upgrade Kit from 2 to 3 Valve Sections - BL15944

Lever M-ICV, 3 Function, DIV + GSS - BL15620

Mech. Midstack Upgrade Kit from 2 to 3 Valve Sections - BL15464

Midstack Valve, 2 Function - BL15460

Midstack Valve, 3 Function - BL15461

Oil Lines, ICV - BL15527

Front Weights

Front Shield - AL157298

Front Weight Support, 110 Kg - AL176565

Pick Up 900 kg (Monoblock) - BL15083

Fuel Tank

Heater And Air Conditioning

Lighting

1 Work Light H3, On Beacon Light Bracket - AL205916

2 Headlights H4, Beltline Mounted (Upright Position) - BL15035

2 Headlights H4, Beltline Mounted (Upright Position) - AL205881

2 Led Working Lights, Rear Fender-Mounted - BL15718

2 Work Lights Front Roof Mounted - BL15844

2 Work Lights HB3, Roof Mounted, Adjustable, Front or Rear - AL205913

2 Work Lights LED, Roof Mounted, Adjustable - BL15717

2 Work Lights Roof Mounted, HB3, Fixed, Side - AL205912

2 Work Lights, Roof Mounted,LED,Front or Rear - BL15999

2 Working Lights HB3, Fender-Mounted, Rear - AL204759

2 Working Lights LED, Beltline-Mounted - BL15719

Beacon Light, on Left Side of Cab-Roof - AL204758

Beacon Light, on Right Side of Cab-Roof - BL15022

Bracket For Installation Of Headlights And Work Lights - BL15243

Extremity Light Preparation Kit for North America - AL204476

Instalation Brackets for Headlight and Work Lights - AL205884

Miscellaneous

Holder for Hitch Cable (ROPE) - BL15403

Latch, Vandal-Kit, Transmission Oil Filler Neck - BL15869

Lockable Filler Cap DEF-Tank - AL211572

Lockable Filler Cap Fuel Tank - AL213203

Security Door Lock Kit - BL15804

Tool Box - AL204829

Operator's Station

Pick-up Weights

Radio

Radio Deluxe with CD - BL15387

Radio Premium for Region 4 - BL15388

Rear Fenders

Rear Fender Extension 200x23 - BL15018

Rear Fender Extension, Additional - BL15879

Rear Hitch

Rear Hitch Equipment

Rear Power Take-off (Pto)

Rear Wheel Weights

Adapter for Rear Wheel Weights Quick Mount, BCD = 275 - BL15909

Adapter for Rear Wheel Weights Quick Mount, BCD = 335 - BL15894

Seat

Backrest Extension for Operator Seats - AL204297

Comfort Seat - Air Suspended - BL15037

Instructional Seat - BL15226

Super Comfort Seat - BL15038

Super Comfort Seat - BL15727

Ultimate Seat - BL15954

Ultimate Seat - BL15955

Selective Control Valves

Additional Hydraulic Oil Reservoir - BL15503

Free Oil Return, ISO 17567-Class 2 - BL15433

Free Oil Return, Size 20 - BL15436

Implement Side, Flat Face Coupler Drain Case, Size 10, ISO 16028 - BL15813

Implement Side, Flat Face Coupler PB, Size 20, ISO 16028 - BL15812

Power Beyond Connectors, ISO 17567 - BL15432

Power Beyond Connectors, Size 12,5 - BL15435

Power Beyond Connectors, Size 20 - BL15434

Selective Control Valves (Scvs)

E-SCV, 450 Series, POS. 3 - BL15963

E-SCV, 450 Series, POS. 4 - BL15964

E-SCV, 450 Series, POS. 5 - BL15965

E-SCV, 450 Series, POS. 6 - BL15966

Lever SCV Position 3 - BL15615

Lever SCV Position 4 - BL15616

M-SCV, 200 Or 450 Series POS. 4 - BL15455

M-SCV. 200 Or 450 Series POS. 3 - BL15454

Stabilizer

Transmission

Weights

Reviews

1 reviews

- Filter

- Star Rating

- Value

- Quality