450E ROUND BALER

Round Baler

- Makes tight and dense 4’ x 5’ bales

- Exclusive DiamondTough™ triple weave belts

Apply For Financing

Features

Regular pickup offers large feed opening and low-profile, mid-mounted pickup

Regular pickup on 450E Baler with converging wheels

Regular pickup on 450E Baler with converging wheels

Mounted in front of the baler wheels and directly below the bale chamber, the pickup hugs the ground for clean crop retrieval. Hay movement is minimized.

- V-belt driven

- 450E and 450M Baler pickups are 116.6 cm (45.9 in.) wide

- Large reel shaft and reel bearing

The small-diameter, low-profile pickup allows for good ground gauging and clean crop retrieval.

- Handles large, heavy windrows of hay and high-moisture crops

- Feeds hay directly to the forming chamber to reduce crop loss

- Low-profile pickup minimizes hay lift to reduce chaffing and retain hay quality

Side flares prevent hay from blowing off the pickup ends, which reduces hay loss.

The closely-spaced pickup teeth extend to the baler side sheets to help build straight-edged bales.

Standard on regular pickups, compressor rods are contoured to control hay over the pickup radius for positive feeding. The compressor rack can be adjusted upward or downward to match the volume of material in the windrow and can be easily removed to match crop conditions.

Adjustable crank handle

Adjustable crank handle

The adjusting crank positions the pickup to the desired operating height to match crop or field conditions.

An optional hydraulic pickup lift cylinder is available as an attachment.

- Makes raising for transport or clearing obstructions easy

- Crank handle serves as a down stop

- Adapts to regular and MegaWide™ Plus pickups

- Hydraulic pickup lift comes standard on premium machines

NOTE: Crank is not an option for the MegaWide High Capacity and Cutting (HC2) feed system.

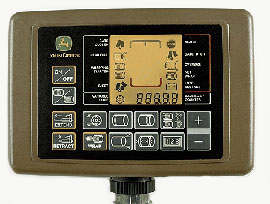

Automatic electric-tie option using BaleTrak™ Pro monitor allows for more productivity

Audible alarm

BaleTrak Pro monitor-controller

BaleTrak Pro monitor-controller

The BaleTrak Pro monitor-controller is included with the automatic electric twine tie option and the Edge-to-Edge net wrap option on the 450E Baler. The monitor sounds an alarm for near-full, full, and oversized bales.

- Monitor beeps once to notify the operator to even-up the bale prior to reaching the desired size.

- Monitor beeps twice when the bale reaches the desired size.

- If the operator continues to feed hay into the baler, the monitor will sound continuously to warn of an oversized bale.

- Bale shape bars are not available on the 450E Round Balers. The 450E Round Balers allow for adjustment of twine settings from the cab by using the BaleTrak Pro Monitor.

- The number of wraps on the Edge-to-Edge net wrap option on the 450E can be set with the BaleTrak Pro.

The audible level of the monitor can be adjusted.

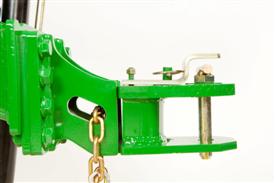

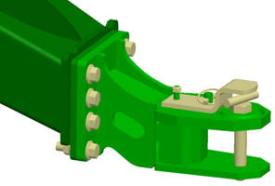

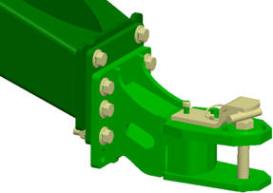

Adjustable hitch to match wide array of tractor drawbar heights

Side view of adjustable hitch

Side view of adjustable hitch

Front view of adjustable hitch

Front view of adjustable hitch

The 0 Series Round Balers came standard with an adjustable hitch and this feature will continue to be in base with the 0 Series Round Balers. This feature allows the hitch height to be adjusted to optimize crop-feeding performance. Due to the wide array of tractor tire sizes and drawbar heights, hitch adjustment may be necessary to get the proper feed opening of the baler. The adjustable hitch eliminates the need for the 51-mm (2-in.) thick tractor drawbar kit (AE57344) because it has a wider opening.

Benefits of the adjustable hitch:

- Ability to match baler to numerous tire sizes

- Allows for drawbar height to fall within 330 mm to 559 mm (13 in. to 22 in.) from the top of the drawbar to the ground

- Eliminates narrow feed opening on the baler which can cause plugging

- Allows pickup head to follow terrain without missing crop

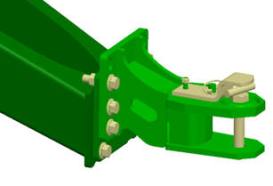

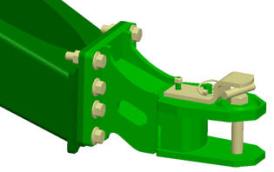

All eight bolts must be used when adjusting the hitch. There are four different positions as shown below:

Position 1 (top) (factory setting) - regular pickups

Position 1 (top) (factory setting) - regular pickups

Position 2

Position 2

Position 3 (factory setting) - MegaWide Plus and MegaWide HC2

Position 3 (factory setting) - MegaWide Plus and MegaWide HC2

Position 4 (bottom)

Position 4 (bottom)

Vertical forming chamber maintains uniform bale density

Bale-starting diagram

Bale-starting diagram

As the hay enters the forming chamber from the pickup, belts immediately turn the hay to form a tight, dense core.

Incoming hay then feeds between the bale and the lower gate roll. Hay is tightly compressed into smooth, dense layers as it enters the bale.

Chaffing is greatly reduced to prevent loss and retain hay quality in the bale.

Full-sized bale in bale chamber

Full-sized bale in bale chamber

The idler arm rises with bale growth, forcing oil from the hydraulic cylinder through a pressure-relief valve to maintain uniform bale density throughout the bale-forming process.

Exclusive DiamondTough™ belts with plate-type splices

Staggered belts

Staggered belts

John Deere's 178-mm (7-in.) wide diamond-tread design ensures fast bale starts and grips the bale to prevent slippage and reduce chaffing. The treads are self-cleaning to reduce carryover. The belts are staggered to reduce the loss of fine material and are closely spaced to contain the hay for fast, easy starts.

The belts enclose 91 percent of the bale width to reduce loss of fine material and retain hay quality.

The staggered belt roll design enables any loose hay under or behind the belts to be returned to the pickup and into the baler. This design helps to prevent buildup at the front of the baler, which could cause hay loss and belt or splice damage.

DiamondTough triple-weave belts

DiamondTough triple-weave belts

Every baler in the 0 Series Family uses DiamondTough belts. Belts are constructed using a patented triple-weave process of nylon and polyester materials.

They have the strength to handle heavy shock loads and help maintain consistent belt length.

The DiamondTough belts are more puncture and tear resistant than other belts on the market and provide improved belt life and reliability.

Plate-type fasteners

Plate-type splices

Plate-type splices

All of the 0 Series Balers use the plate-type fasteners.

This closed-loop design uses a plate fastener with pre-assembled rivets that lock the fasteners into the belt, providing a powerful vice-type grip on the belt.

- The plates and rivets are manufactured from high-tensile stainless steel.

- Strong belt splices mean less maintenance and more productivity.

- The loop area is cold forged, making it extremely wear resistant in the coupling area, resulting in a very long cycle life.

- The spring steel pin is notched and locks into the splice connection without having to bend the pin or use external retainers.

Specifications

Compare the specifications of up to 4 models

| Key Specs | 450e-round-baler Current Model |

|---|---|

| Belts-other - width | 17.8 cm 7 in. |

| Density control | Hydraulic |

| Bale size indication | Not available from factory, available as dealer-installed options |

| Regular pickup - Bars | Four |

| Regular pickup - Number of teeth | 72 |

| Regular pickup - Tooth spacing | 6 cm 2.6 in. |

| Bale | |

| Size | Diameter 89 - 152 cm 35 - 60 in. Width 117 cm 46 in. 1.2 x 1.5 m 4 x 5 ft |

| Weight | Full-size bale in dry crop 454 kg 1,000 lb |

| Baler | |

| Weight | Shipping - 1,701 kg 3,750 lb |

| Length | Gate closed 361 cm 142 in. Gate open 455 cm 179 in. |

| Height | Gate closed 260 cm 102 in. Gate open 325 cm 128 in. |

| Width | With standard tires 226 cm 89 in. |

| Bale forming | |

| Belts-other | Number Six Width 17.8 cm 7 in. Texture Diamond Tread friction surface belts DiamondTough, triple-weave, single-ply belts |

| Density control | Hydraulic |

| Bale size indication | Not available from factory, available as dealer-installed options |

| Regular pickup | |

| Width | Inside 117 cm 46 in. Flare 141 cm 56 in. |

| Bars | Four |

| Number of teeth | 72 |

| Tooth spacing | 6 cm 2.6 in. |

| Lift control | Adjustable height control |

| Gauge wheels | Semi-pneumatic |

| Stripper diameter | 25.4 cm 10 in. |

| MegaWide Plus pickup | |

| High-capacity pickup | |

| Wrapping system | |

| Control | Automatic to preset to bale size |

| Type | Standard Electric |

| Twine arms | Two |

| Twine ball capacity | Four |

| Monitor | |

| Gate closed | Symbol on monitor |

| Bale size | Mechanical |

| Near full bale | Audible alert |

| Full bale | Audible alert |

| Twine arm position Indicator | Mechanical |

| Auto wrap | Activates when bale reaches preset size |

| Oversize bale | Yes, audible and mechanical alerts |

| Surface wrap | |

| Tire size | |

| Standard | 11 L - 14 |

| Driveline | |

| Drive protection | Shearbolt |

| PTO speed | 540 rpm |

| Type | Constant-velocity (CV) |

| PTO lockback collar on tractor hookup | No |

| PTO 60-degree free rotation | No |

| Tractor Requirements | |

| Minimum PTO | Dry Hay and Silage - 42 kW 55 hp |

| Hydraulic SCV valves | One tractor selective control valve (SCV) is required when baler is equipped with electric twine wrap. Two tractor SCVs are required when baler is equipped with hydraulic twine wrap. Three tractor SCVs are required when baler is equipped with hydraulic twine wrap and a hydraulic pickup lift. |

| Silage baler features |