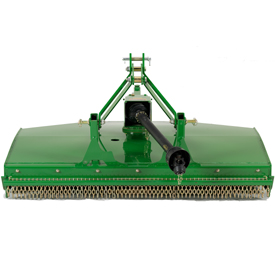

MX5 ROTARY CUTTER

Rotary Cutter

- Standard stump jumper blade holder

- Dome-shaped top deck is smooth and easy to clean

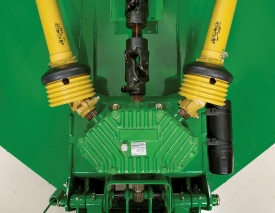

- 3-point hitch hookup provides more strength

- Front and rear chain shields offer safety

Maintenance Plans

Features

What is the best cutter for your job?

NOTE: Only for single spindle and multi-spindle.

John Deere rotary cutters lead the way with innovative design, superior performance, and proven durability. Valuable features such as the Double-Decker™ design and Max Flow cutting chamber prevent water and debris from accumulating on the smooth, dome-shaped top deck while the flat bottom deck absorbs the punishment from rocks and stumps.

The top deck stays smooth - no dents, no dings, no holes. The internal supports sandwiched between the top and bottom decks are key to the smooth and structure-free Max Flow cutting chamber, while at the same time provide added strength and durability.

To help promote safe operation, John Deere rotary cutters are equipped with front and rear safety-chain shields. John Deere rotary cutters continue to advance in value with powerful gearboxes, blade holders, and compatibility with a wide range of tractors.

Here are situations when a rotary cutter provides value:

-

Clipping pastures encourages grass growth, optimizing valuable pasture acreage.

-

Cutting grass and stalks helps control insects.

-

Routine cutting keeps weeds from reseeding.

-

It is the most cost efficient way to cut roadsides, parks, cemeteries, airport fields, hydro, gas, and telephone easements, and all other types of open properties.

-

Cutting grass waterways encourages root development and helps prevent erosion.

-

Knocking down stalks such as cotton, corn, or milo speeds up decomposition. This is essential in no-till and minimum-till fields.

-

Clearing out brush.

-

Control undergrowth and grass in orchards, vineyards, and groves.

Decide what model to use based on:

- The size of the area to mow versus the size of the machine – the bigger the area to mow, the bigger the mower needs to be in order to be efficient during mowing hours. Similarly, the limitation of a small area will guide operators to use a smaller mower.

- The amount of time and frequency it will be used – for longer hours and more frequency, choose a heavier duty machine.

- Tractor compatibility – if there is a tractor the operator will be using, look for the tractor compatibility sheet to identify appropriate options.

John Deere rotary cutters are available in two duty-level categories:

-

Mid-duty

-

MX models are available in 1.5-m (5-ft), 1.8-m (6-ft), 2.1-m (7-ft), 2.5-m (8-ft), and 3.2-m (10-ft).

-

This duty-level category cuts brush up to 50.8 mm (2 in.) in diameter.

-

-

Heavy-duty

-

HX models are available in 3.2-m (10-ft) and 4.2-m (14-ft).

- This duty-level category cuts brush up to 76.2 mm (3 in.) in diameter.

-

HX6 is available in 1.8-m (6-ft) and the HX7 is available in 2.1-m (7-ft) cut widths; they cut brush up to 101.6 mm (4 in.) in diameter.

-

NOTE: HX models are heavier built to cut at a 101.6 mm (4 in.) capacity level more frequently and for longer durations.

Front and rear safety chain shields are standard

Front safety chains (MX6 shown)

Front safety chains (MX6 shown)

Rear safety chains (MX6 shown)

Rear safety chains (MX6 shown)

Front and rear chain shields are standard equipment:

- Offer protection for the operator yet allow uncut material to pass into the cutting chamber with minimal restriction

Standard suction blades provide additional blade lift

Suction blade (standard equipment)

Suction blade (standard equipment)

Suction blades provide additional lift action for picking up downed material. The blades are 1.3 cm x 10.2 cm (0.5 in. x 4 in.) in size and heat-treated for long wear life.

The fast blade-tip speed ensures clean cutting and fine shredding of material.

- Up to 88.5 m/sec (17416 fpm)

Warranty

Five-year limited gearbox warranty provided on every John Deere rotary cutter

Five-year warranty on all flex-wing gearboxes

Five-year warranty on all flex-wing gearboxes

Five-year warranty on all rotary cutter gearboxes

Five-year warranty on all rotary cutter gearboxes

John Deere is so confident in the reliability of the gearbox that rotary cutters come with a 5-year limited gearbox warranty.

There is also 1-year warranty on the complete machine, including drivelines, clutches, and many other components.

Specifications

Compare the specifications of up to 4 models

| Capacity | mx5-rotary-cutter Current Model |

|---|---|

| Cutting width | 1,524 mm 60 in. |

| Cutting height | 25 to 241 mm 1 to 9.5 in. |

| Cutting capacity | 51 mm 2 in. |

| Cutting chamber Depth | 216 mm 8.5 in. |

| Tractor compatibility | |

| Tractor PTO HP range | Minimum 19 kW 25 hp |

| Tractor PTO | 540 rpm |

| Hitch | |

| Type | Lift-type |

| Category | 1; or convert to 2 |

| Dimensions | |

| Transport width | 1,651 mm 65 in. |

| Overall width | 1,651 mm 65 in. |

| Overall length | 2,591 mm 102 in. |

| Deck shape | Domed |

| Deck type | Double decker |

| Deck thickness | Upper 3 (11) mm 0.118 (11) in. Lower 3 (11) mm 0.118 (11) in. |

| Side skirt thickness | 0.25 (3) in. 6 (3) mm |

| Approx. weight | 374 kg 823 lb |

| Drivelines | |

| Size | Main ASAE Category 3 |

| Protection | Main Slip-clutch driveline |

| Gearcases | |

| Number | 1 |

| HP rating | Center Continuous 56 kW 75 hp Peak 67 kW 90 hp |

| Blades | |

| Thickness | 13 mm 0.5 in. |

| Width | 102 mm 4 in. |

| Type | Suction |

| Blade tip speed | 540 RPM 4,304 m/min 14,121 fpm 258 km/h 160 mph |

| Material flow system | Max flow |

| Holder | Type Round stump jumper |

| Wheels | |

| Type | Puncture proof laminated |

| Shielding | |

| Front | Chain |

| Rear | Chain |

| Key Specs |