520 FLAIL SHREDDER

Drawn Flail Shredder

- Front rubber deflectors

- Heavy-duty gearbox

- Steel rotor bearings

- Square rotor designed for superior strength

Maintenance Plans

View Product Brochure

Features

Drawn or integral model available to meet a variety of applications

Hitch

Hitch

Drawn

Drawn

Square rotor designed for superior rotor strength

Rotor

Rotor

Designed for superior rotor strength, the square rotor, together with the opposite-mounted flails, provides a machine with less potential vibration, increasing the life of rotor bearings and belts.

Since 248 knives are mounted on the full length of the rotors on the main cutterbar, with 2.5 cm (1 in.) of overlap, a stalk won't get missed. This is a significant improvement over the 216 knives mounted on the previous 220 Flail Shredder.

Rubber deflectors will not dent or rust

Rubber deflectors

Rubber deflectors

Flail fastening system eliminates clogging from mud or crop residue

Flail fastening system

Flail fastening system

The flail fastening system eliminates clogging from mud or crop residue. Its bracket design also helps prevent knife and ring loss.

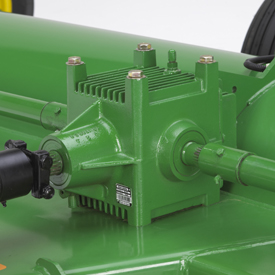

Heavy-duty John Deere-designed gearbox

Gearbox

Gearbox

A heavy-duty, John Deere-designed and John Deere-built gearbox transfers power to the Kevlar® drive belts through cross shafts with intermediate bearing supports:

- The transmission is bolted directly to the frame.

- This gearbox has a constant-duty rating of 180 hp and a maximum rating of 270 hp.

- It carries a limited two-year warranty.

Kevlar is a U.S.-registered trademark of E.I. du Pont de Nemours and Company.

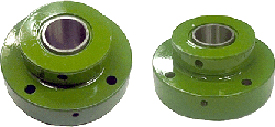

Steel rotor bearings for increased bearing life

Rotor bearings

Rotor bearings

The rotor bearings are now made of steel and have a three-lip seal to keep the dirt out and increase the life of the bearings.

The side and center bearings now have guards in order to avoid leaks and dust, increasing the life of the bearings.

Optional wheel supports eliminate uncut middle strip in non-row-crop field

Wheel supports

Wheel supports

Optional wheel supports eliminate the uncut middle strip in crops like wheat, oats, and barley. The shredder can be pulled at an angle, offsetting the rotors and cutting evenly across the entire width of the machine.

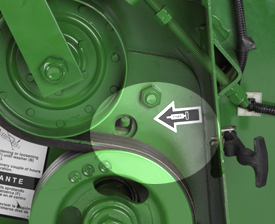

Serviceability

Lateral-bearing service access

Lateral-bearing service access

Center-bearing service access

Center-bearing service access

Hard-to-reach center bearings can be serviced with the conveniently located grease fittings at the rear of the machine:

- There is no need for the operator to crawl under the machine to perform this service task, thus increasing the probability of the job being performed and completed safely.

Specifications

Compare the specifications of up to 4 models

| Power requirements | 520-flail-shredder Current Model |

|---|---|

| Tractor PTO hp range | Minimum 89 kg 120 hp |

| Tractor RPM | 1,000 rpm |

| Knives | |

| Number of knives | 248 side slicer (124 pairs) |

| Knife dimensions | 7.87 x 63.5 mm 0.31 x 2.5 in. |

| Knife mounting system | Bracket and D-ring |

| Type | Alloy steel, hardened with vanadium carbide and reversible |

| Knives overlap | 27.18 mm 1.07 in. |

| Tip speed | 224 km/h 139 mph |

| Rotor | |

| Rotor speed | 2,000 rpm |

| Rotor diameter | Square rotor 17.8 x 17.8 cm 7 x 7 in. |

| Rotor bearing | Double-row, barrel-type, triple-sealed, 2-year warranty |

| Bearing size | 42.86 mm 1.69 in. |

| Drivetrain | |

| Belts | Kevlar, 3/5V heavy-duty |

| PTO drivelines | 44.5 and 35.1 mm 1.75 and 1.38 in. |

| Mainframe | |

| Hitch | Drawn or Integral (Cat. 3 or 3N Quik-Coupler required) |

| Safety deflector | Rubber deflector |

| Gauge wheels | 4 (Drawn), 2 (Integral); infinitely adjustable |

| Warning lights | Integral (standard), drawn (optional) |

| Cutting capacity | |

| Cutting width | 6.1 m 20 ft |

| Cutting height | 7.6-25.4 cm 3-10 in. |

| Dimensions | |

| Transport width | Endwise; drawn 2.39 m 7.83 ft Integral 6.48 m 21.25 ft |

| Transport length | Endwise; drawn 7.34 m 24.08 ft Integral 2.39 m 7.83 ft |

| Weight | 2,268 kg 5,000 lb |

| Optional equipment | |

| Easy transport | Available |

| Constant velocity joint driveline | Available |

| Skid shoes | Available |