9R 590

Tractor

- Engine HP1: 649 Max / 590 hp Rated

- Fully integrated precision ag technology

- e18™ PowerShift Transmission

- Choice of three different cab and visibility packages

1Engine power PS (hp ISO) at max engine power speed (ECE-R120). John Deere Standard RES10080, SAE Standards J1995.

Apply For Financing

View Product Brochure

Features

JD14 (13.6L/827-cu in.) engine: real world usability, not just power on paper

JD14 engine

JD14 engine

The muscle to handle heavy draft disks and rippers, power-hungry air seeders and planters, and large transport loads like grain carts and slurry wagons. The durable design and heavy-duty components you can depend on when you need to get in and get out. All in a Final Tier 4 (FT4) and Stage V compliant package. You get real-world power with the purpose-built JD14 (13.6L/827-cu in.) engines from John Deere Power Systems, standard in the 291 to 471 engine kW (390 to 640 engine hp) 9 Series Tractors.

We developed our newest power plant from a clean sheet of paper, starting with stronger castings, beefier bearings, and more robust internal components, all designed to meet the high demands of field operations. We replaced the fuel injectors with a high-pressure common rail (HPCR) fuel system and eliminated the diesel particulate filter (DPF) to boost to fuel efficiency and lower operation and maintenance costs. Integrated coolant and oil passages, along with a new belt-driven water pump, eliminate potential leak points and allow for a less-crowded engine compartment, improving serviceability and reducing debris accumulation.

In redesigning the engine, we also gave it:

- Hydraulic valve lash adjusters to maintain valve-lash settings during engine operation, reduce valve train noise and wear, and allow for greater fuel efficiency.

- A hydraulic fan drive for improved cooling capacity with no required maintenance.

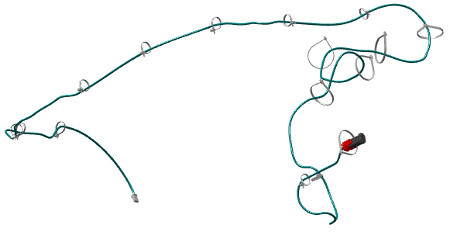

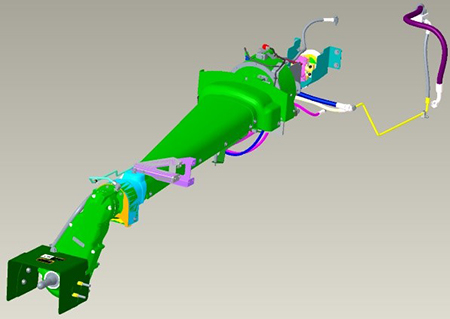

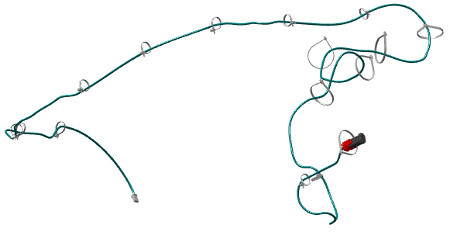

- A new integrated wiring harness design featuring a modular layout for reduced vibration, greater reliability, and easier service and diagnostics.

- A rear gear train that integrates fully into the cast-iron block, reducing tiresome engine noise and improving the durability of the crankshaft damper.

- Combination sensors where possible, meaning fewer sensors, connectors, and wires.

- A powerful engine brake that allows operators to use the engine to control tractor and implement speeds while transporting or traveling downhill, reducing wear on the drivetrain brake components.

It all adds up to:

- 14 percent more power and 11 percent more torque

- 3 percent lower fuel consumption

- 10 percent lighter

- 13 percent reduction in mean repair time and an estimated $8,308 savings in service costs over the life of the engine

13.5L (824-cu in.) engine compared to JD14 (13.6L/827-cu in.) engine

| Feature | 13.5L (824-cu in.) engine | JD14 (13.6L/827-cu in.) engine |

| Fuel delivery | Electronic unit injectors (EUI) | HPCR |

| Aftertreatment | Two canisters | One canister |

| Valve lash adjustment | Manual | Automatic |

| Engine brake | Not available | Available above 402.7 kW (540 hp) |

| Wire harness | Single harness | Three short harnesses |

| Water pump | Gear driven | Belt driven |

| Gear train | Front mounted | Rear mounted |

| Fan drive | Vari-Cool™ system | Hydraulically driven |

NOTE: The PowerTech™ 13.6L (827-cu in.) engine has been renamed the JD14.

9 Series Visibility packages let you run with confidence, dawn until dusk

Ultimate Visibility package at night

Ultimate Visibility package at night

Visibility is more than just lighting. It’s mirrors where you need them, shades for the blinding late-fall and early-spring sun, wipers to help keep all the glass clear, and integrated camera capability. The new 9 Series Tractors let you choose the visibility package that best suits your needs – Select, Premium, or Ultimate with 360-degree light-emitting diode (LED) lighting –so you and your operators can run with all-conditions confidence.

| Select | Premium | Ultimate | |

| Lighting | 18 halogen worklights | 18 LED worklights | 24 LED worklights and eight LED convenience lights* |

| Mirrors | Mechanical | Electric and heated | Electric, heated, and telescoping |

| Sunshades | Front | Front, right-hand side, and rear | Front, right-hand side, and rear |

| Wipers | Front and rear | Front, right-hand side, and rear | Front, right-hand side, and rear |

| Cameras | Camera ready | Camera ready | Camera ready** |

*Convenience lights illuminate the corners of the cab for easier entry and exit.

** Starting with model year 2022, the Ultimate Visibility package is camera ready.

Put more power to the ground, more comfortably, with the industry-exclusive HydraCushion™ suspension

9R 640 equipped with HydraCushion suspension

9R 640 equipped with HydraCushion suspension

Power that doesn’t get to the ground is power that’s being wasted. And a bumpy, hoppy ride can quickly drain an operator’s energy and productivity. So to help you get the most from every horse under the hood and every hour in the cab, 9R Tractors in wheeled configurations are available with the advanced, industry-exclusive HydraCushion suspension (HydraCushion is standard equipment on 477-kW [640-hp] models).

Along with a proven-reliable suspension design, HydraCushion suspension uses an advanced system of electronic sensors and hydraulic components to keep the chassis and front differential vertically centered, giving you more consistent contact with the ground while reducing road lope and smoothing out the bumps that cause a rough, tiring ride.

In the field or on the road: adjust steering ratio on-the-go with ActiveCommand Steering (ACS™)

9RX in transport

9RX in transport

You don’t have to compromise between pinpoint turns in the field and smooth, easy steering during transport – you can have it all with ActiveCommand Steering (ACS), available on all 9R and 9RX Tractors.

ACS lets you choose your steering ratio based on the task at hand. For precise headland maneuvers in the field, choose a tight 3.5 turns lock-to-lock. When you’re done in the field, ACS gives you a full five turns for smoother line-holding during road transport. Variable-effort resistance automatically changes with ground speed; you’ll notice a lighter touch during low-speed, in-field turns, and increased feedback at transport speeds for more comfortable, confident steering over the road. Plus, ACS works seamlessly with AutoTrac™ guidance systems and is compatible with wide and narrow section width tires as well as wide and narrow belts on 9RX models.

The end result? Reduced overall steering effort and fatigue, no drift and no backlash through the hand-wheel, all with the “connected” feel of a traditional steering column system

John Deere integrated solutions: a world of connected technology, right from the factory

Maximizing uptime using connectivity and technology

Maximizing uptime using connectivity and technology

John Deere makes it easy for you to access an entire suite of connected applications, all designed to help you make the most of every seed, every hour, every gallon, and every bit of machine-related information.

Each 9 Series Tractor comes standard with the John Deere StarFire™ 6000 Integrated Receiver and Generation 4 CommandCenter™ display; there’s no need for setup, installation, or initial global positioning system (GPS) calibration. Integrated AutoTrac™ assisted steering gives you accurate, scalable guidance for low-stress operation in nearly any conditions and can improve field efficiency by 10 percent or more. The 9 Series Tractors also feature standard JDLink™ telematics and users can turn on connectivity in the John Deere Operations Center for anytime, anywhere access to critical machine and field information. And every tractor comes from the factory with John Deere Connected Support™, so you and your dealer can anticipate and address critical system needs.

From here? The sky’s the limit. Choose any of our operation-specific applications to help maximize efficiency and productivity during planting, tillage, or other field activities.

*NOTE: Ordering is temporarily unavailable for the StarFire 6000 Integrated Receiver. John Deere is diligently working to resolve this issue. Please watch the Price Pages and the announcements in the Sales Manual for updates. We apologize for any inconvenience.

|

|

|

| StarFire 6000 Integrated Receiver | AutoTrac | JDLink |

Base equipment:

Optional equipment:

|

Base equipment:

Optional equipment:

|

Base equipment:

|

*Available with Premium Activation 3.0

**Available with Automation Activation 4.0

Work at your best with 9 Series Comfort and Convenience packages

Ultimate Comfort and Convenience package (shown on 8R Tractor)

Ultimate Comfort and Convenience package (shown on 8R Tractor)

When you’re spending dozens of hours per week in the cab, a comfortable operating environment isn’t just an option – the right features, in the right places, let you and your operators work at your best, dawn to dusk and beyond.

The 7, 8, and 9 Series Tractors offer three Comfort and Convenience packages to fit your needs: Select, Premium, and Ultimate. But regardless of which package you choose, you’ll still get the John Deere CommandARM™ console that puts critical controls within easy reach. You’ll get all the storage space you need for drinks, meals, and other stowable items. And you’ll have plenty of outlets to keep your electronics powered.

| Comfort and Convenience packages | Select | Premium | Ultimate |

| Seat |

|

|

|

| Infotainment |

|

|

|

| Business band ready | X | X | X |

| Four USB and one 12-V outlet | X | X | X |

| Dual tilt column | X | X | X |

| Footrests | --- | X | X |

| Refrigerator | --- | X | X |

| 120-V/300-W three-prong outlet | --- | X | X |

| Carpeted floor mat | --- | --- | X |

| Leather-wrapped steering wheel | --- | --- | X |

Bluetooth is a trademark of Bluetooth SIG, Inc. XM is a trademark of Sirius XM Radio Inc.

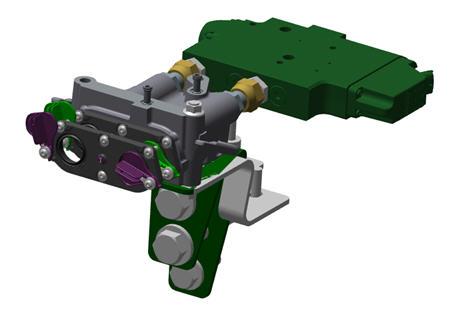

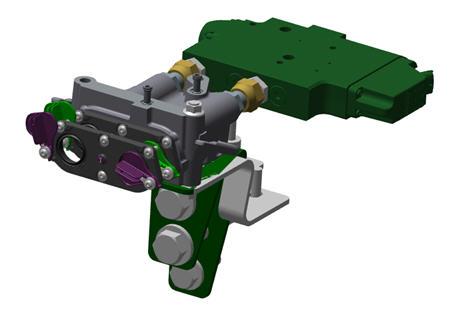

A range of hydraulic options give you the power and flexibility to take on your toughest applications

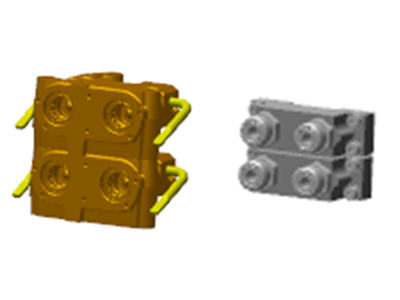

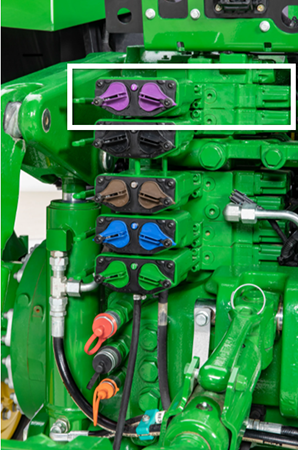

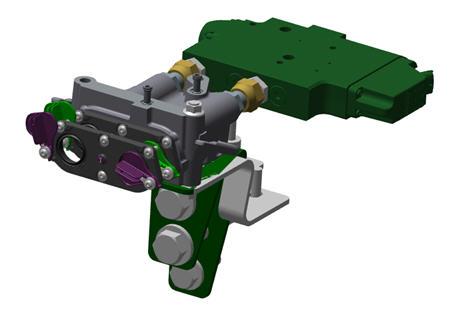

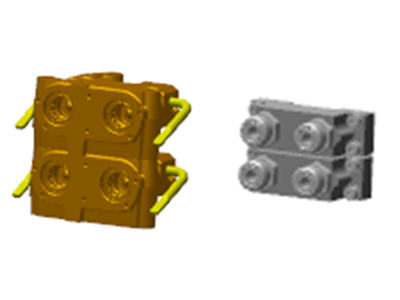

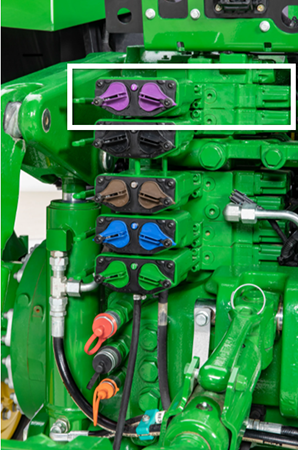

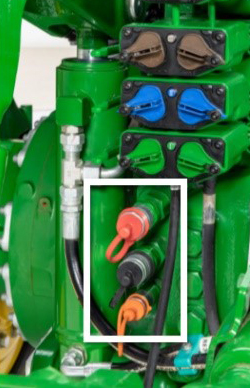

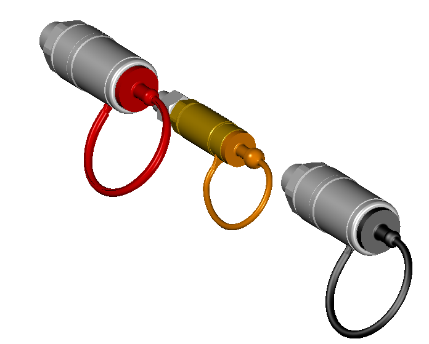

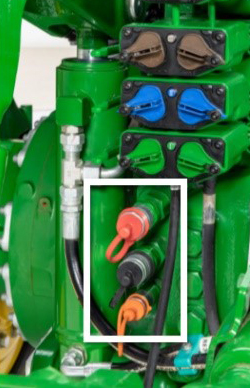

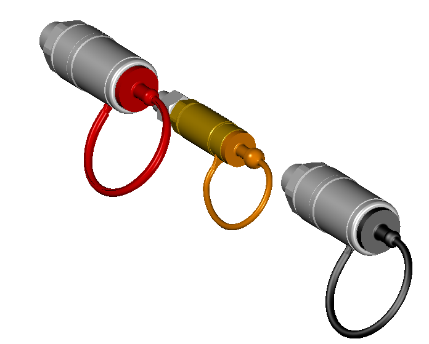

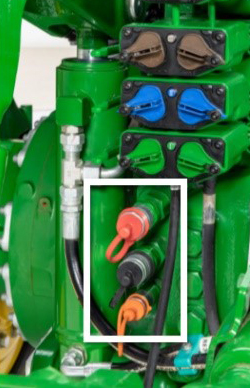

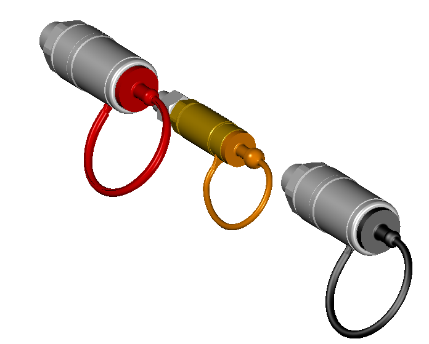

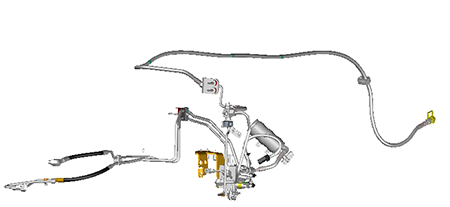

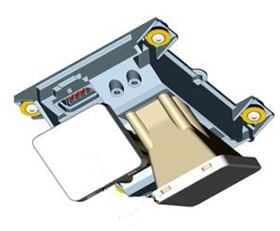

Selective control valves (SCVs) on a 9R Tractor

Selective control valves (SCVs) on a 9R Tractor

Of course, the 9 Series has the hydraulic muscle you need to push, pull, lift, and power your most demanding implements. But thanks to a range of enhancements to the hydraulic system, these tractors can provide that power at lower engine speeds, saving you fuel while still giving your implements the capacity they need. Regardless of model or configuration, the new 9 Series hydraulic system gives you:

- An increase of almost 40 percent in charge pump capacity, from 54-cc to 75-cc, to help maintain a higher flow at lower engine speeds

- A new swash plate angle sensor to monitor hydraulic flow and pressure and adjust engine speed to meet demand

- An integrated hydraulic pump, filter, and priority valve for fewer and shorter lines, reduced pressure loss, fewer flow restrictions, and an extra level of reliability

And if you depend on implements that need continuous hydraulic power, the 9 Series Tractors are available with Intelligent Power Management (IPM). Using dual pumps and advanced sensor and control technology, IPM provides additional engine and hydraulic power for high-demand applications like air seeding up and over hills or through thick, tough soil.

Add in single and dual pump options and a flexible number rear SCVs, and you can configure a powerful, fuel-efficient hydraulic system to meet the demands of your specific operation without paying for capacity you don’t need.

The new 9 Series: Easy to run, easy to maintain

9RX Tractor

9RX Tractor

When you’re trying to get a field planted before weather moves in, there’s no time to hit a scheduled maintenance interval or get smacked with an unexpected repair. That’s why we designed the 9 Series for maximum reliability and less in-season maintenance.

To start, we simplified as many systems as possible, using components common to other tractor lines and minimizing potential downtime due to parts availability. Then we eliminated as many potential pain points as possible through changes in the cooling, aftertreatment, and diagnostic systems, including:

- Replacing the fan drive system with a maintenance-free hydraulic fan drive

- Streamlining aftertreatment with a single-canister inline system that’s simpler and features fewer parts

- Improving uptime by adding better descriptions to diagnostic codes and offering predictive diagnostics through John Deere Expert Alerts

- A front-left service panel for easier access to engine oil check and fill points;

- Offering a 500-hour oil change interval on the John Deere JD14 (13.6L/827-cu in.) Final Tier 4 (FT4) engine when using approved John Deere oil and filter.

Specifications

Compare the specifications of up to 4 models

| Key Specs | 9r-590 Current Model |

|---|---|

| Engine description | JD14 (B20 diesel compatible) |

| Engine displacement | 13.6 L 827 cu in. |

| Rated engine power | 434 kW 590 hp |

| Maximum engine power | 477 kW 649 hp |

| Rated PTO power (hp SAE) | 249 kW 335 hp |

| Maximum PTO power | |

| Transmission type | John Deere e18™ 18-speed PowerShift™ with Efficiency Manager™: 40 km/h 25 mph |

| Hydraulic pump rated output | Standard: 208 L/min 55 gpm Optional: 416 L/min 110 gpm |

| Rear hitch category (SAE designation) | Category 4N/4: 6804 kg 15,000 lb Category 4N/4: 9072 kg 20,000 lb |

| Base machine weight | 20,856 kg 45,980 lb |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

| Engine specifications | |

| Description | JD14 (B20 diesel compatible) |

| Engine type | In-line six, four valve |

| Engine family | MJDXL13.5334 |

| Rated speed | 2100 rpm |

| Aspiration | Dual series turbocharger with fixed geometry first stage and wastegated second stage; air-to-air aftercooling and cooled exhaust gas recirculation (EGR) |

| Cylinders liners | Wet-sleeve |

| Emission level | Final Tier 4 (FT4) |

| After treatment type | Diesel oxidation catalyst (DOC)/selective catalytic reduction (SCR) |

| Displacement | 13.6 L 827 cu in. |

| Engine performance | |

| Rated power | 434 kW 590 hp |

| Rated PTO power (hp SAE) | 249 kW 335 hp |

| Maximum PTO power | |

| Intelligent Power Management (IPM) | |

| Power boost | 10 percent |

| Maximum engine power | 477 kW 649 hp Optional hydraulic IPM: 459 kW 615 hp |

| Engine peak torque | At 1550 rpm: 2723 Nm 2008 lb-ft |

| Drawbar power | |

| PTO torque rise | 38 percent |

| Fuel injection system and control | |

| Air cleaner type | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

| Transmission | |

| Type | John Deere e18 18-speed PowerShift with Efficiency Manager: 40 km/h 25 mph |

| Reverser | |

| Clutch; wet/dry | |

| Creeper | |

| Hydraulic system | |

| Type | Closed-center, pressure-and-flow compensated |

| Pump rated output | Standard: 208 L/min 55 gpm Optional: 416 L/min 110 gpm |

| Available flow at a single rear SCV | 1.3-cm (1/2-in.) couplers: 132 L/min 35 gpm 1.9-cm (3/4-in.) couplers: 159 L/min 42 gpm |

| Available flow at front SCVs | |

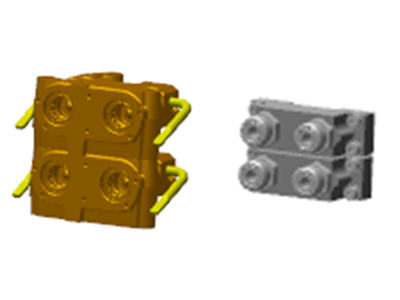

| Number of rear selective control valves (SCVs) | Four to eight factory or field installed Base: four 1.3-cm (1/2-in.) couplers Optional: five to six 1.3-cm (1/2-in.) couplers factory installed Optional: three 1.9-cm (3/4-in.) couplers plus five 1.3-cm (1/2-in.) couplers factory installed |

| Number of mid selective control valves (SCVs) | |

| Number of front selective control valves (SCVs) | |

| Joystick SCV control | |

| Auxiliary hydraulic features | |

| SCV control | Electronic |

| Rear hitch | |

| Hitch draft control load sense type | |

| Remote control valves available | |

| Hitch category (SAE designation) | Category 4N/4: 6804 kg 15,000 lb Category 4N/4: 9072 kg 20,000 lb |

| Maximum lift capacity behind lift points | Category 4N/4: 9072 kg 20,000 lb |

| Lift capacity at standard frame | |

| Sensing type | Electrohydraulic with draft sensing |

| Rear axle differential lock | |

| Drawbar | |

| Drawbar category | Category 5 |

| Maximum vertical load | 5440 kg 12,000 lb |

| Rear power take-off (PTO) | |

| Type | Independent 44 mm (1.75 in.) 20-spline, 1000 rpm |

| Engine rpm (at rated PTO speeds) | |

| Economy PTO speeds | |

| Reverse PTO speeds | |

| Multispeed PTO option availability | |

| Ground speed PTO option availability | |

| PTO actuation | Electrohydraulic |

| Front hitch | |

| Category | |

| Electric power | |

| Standard lift capacity | |

| Front power take-off (PTO) | |

| PTO speed | |

| Rear axle | |

| Type | Diameter: 120 x 3048 mm 4.72 x 120 in. |

| Final drive type | Inboard planetary with double-reduction axle |

| Differential controls | |

| Axle type | |

| Brakes, type and control | |

| Rear differential lock | Full-locking electrohydraulic |

| Load rating | |

| Front axle | |

| Type | Diameter: 120 x 3048 mm 4.72 x 120 in. |

| Front axle differential lock | Full-locking electrohydraulic |

| Load rating | |

| Tires | |

| Rear | |

| Wheel tread range | |

| Turning radius with brakes | Group 48 tires: 6.099 m 20 ft |

| Turning radius without brakes | |

| Central Tire Inflation System (CTIS) | |

| Front | |

| Tracks | |

| Tread spacing | |

| Drive type | |

| Track width | |

| Mid-rollers | |

| Steering | |

| Brakes | |

| Primary brake (foot brake) | |

| Secondary brake | |

| Park lock | |

| MFWD braking | |

| Front axle brakes | |

| Auxiliary brakes | |

| Hydraulic trailer brakes | |

| Pneumatic trailer brakes | |

| Electrical system | |

| Alternator size | Standard: 250 amp Optional: 330 amp |

| Battery options | 12 V |

| Working lights | Standard: 18 halogen Optional: 18 or 24 LED plus 8 LED conveninence lights |

| Type of bulb in headlight (Halogen, Zenon, LED) | Standard: halogen, 65 W Optional: LED |

| Type of bulb in beacon (Halogen, Zenon, LED) | |

| dB(A) rating for backup alarm | |

| Total cold cranking amps | 3 x 925 CCA Total: 2775 CCA |

| Operator station | |

| Rollover protective structure, OOS | |

| Seat | Degree of seat swivel, left hand 25 degree (angle) Degree of seat swivel, right hand 40 degree (angle) Standard: air suspension Optional: ActiveSeat™ II |

| Cab suspension | |

| Instructional seat | Standard |

| Display | Standard: Generation 4 4600 CommandCenter™: 25.4 cm 10 in. Optional: Extended monitor |

| Radio | Standard: AM/FM stereo with weatherband, remote controls, auxiliary input jack, four speakers and external antenna Optional: Touchscreen radio |

| Inner cab volume | 3.27 m3 115 cu ft |

| dB(A) rating | |

| Cab glass area | 6.64 m2 71.47 sq ft |

| Safety glass rating | |

| Front visibility | |

| Dimensions | |

| Wheelbase | 3912 mm 154 in. |

| Overall width | |

| Overall length | With front weights, excluding hitch and coupler: 7945 mm 312.8 in. With front weights, including hitch and coupler: 8427 mm 331.8 in. |

| Overall height | |

| Drawbar clearance | Group 48 tires: 527 mm 20.7 in. |

| Front axle center | |

| Approximate shipping weight, Open;Cab | 20,856 kg 45,980 lb |

| Weight | |

| Base machine weight | 20,856 kg 45,980 lb |

| Maximum ballast level | 30,391 kg 67,000 lb |

| Maximum permissible weight | |

| Capacities | |

| Crankcase oil volume | 64 L 16.9 U.S. gal. |

| Fuel tank | 1514 L 400 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | 120 L 31.7 U.S. gal. |

| Cooling system | 56.5 L 14.9 U.S. gal. |

| Transmission-hydraulic system | With 3-point hitch and PTO: 227 L 60 U.S. gal. Without 3-point hitch and PTO: 220 L 58 U.S. gal. |

| Serviceability | |

| Interval for engine oil change | 500 hours |

| Interval for hydraulic/transmission oil change | 1500 hours |

| Interval for engine coolant change | 6000 hours |

| Loaders | |

| Loader | |

| Lift capacity at full height | |

| Maximum lift height | |

| Leveling type | |

| Precision AG | |

| Guidance | Integrated AutoTrac™ |

| Telematic | Available with JDLink™ hardware, activations, and Ethernet harnesses (availability dependent upon destination) |

| Remote diagnostics | Available with activated JDLink hardware and activations |

| Miscellaneous | |

| AutoTrac ready | |

| ISOBUS ready | |

| CommandCenter video inputs | |

| Immobilizer | |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Country of manufacture | USA |

Accessories and Attachments

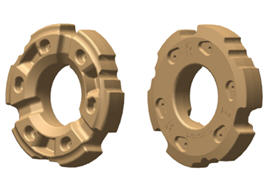

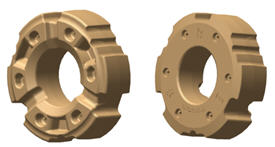

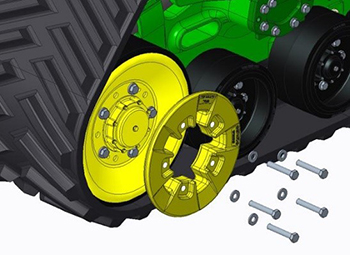

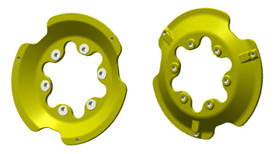

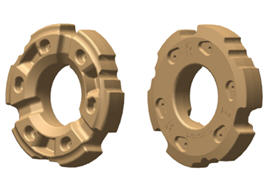

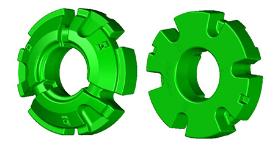

Axle

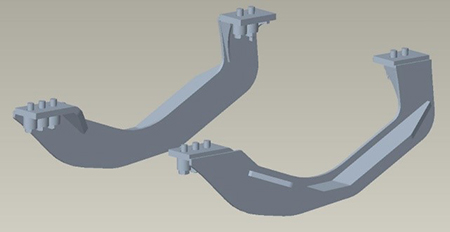

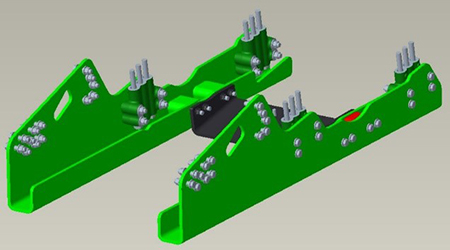

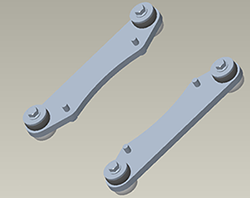

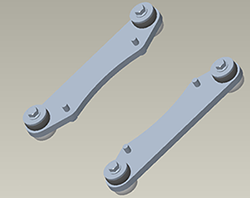

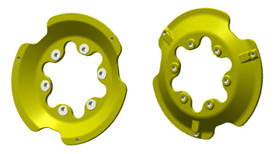

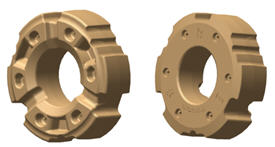

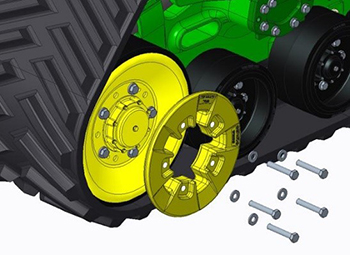

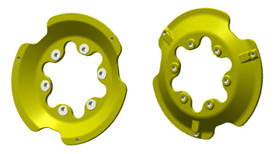

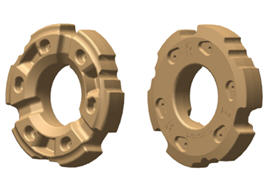

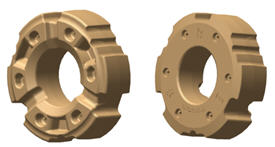

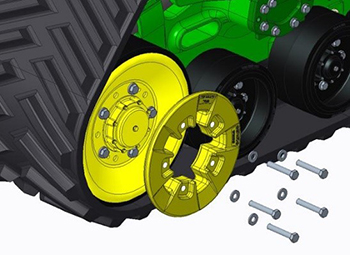

Front supports (9R Wheel Tractor)

Front supports (9R Wheel Tractor)

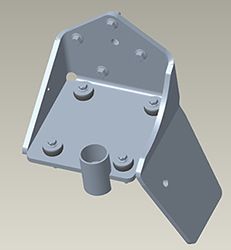

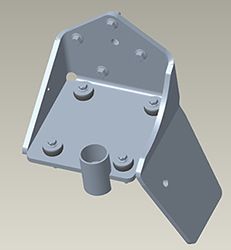

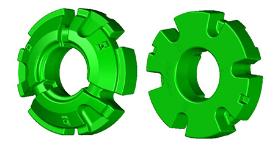

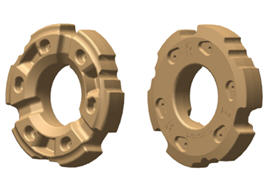

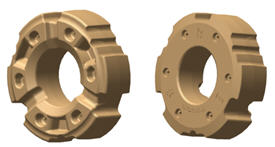

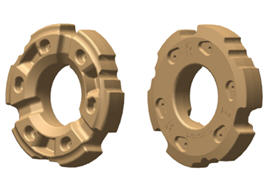

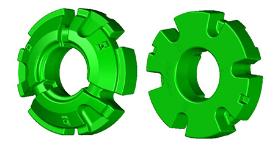

Front frame support (9RX Tractor)

Front frame support (9RX Tractor)

Front frame and axle support kits provide additional support to the front frame and axle joint when the tractor is used in applications that put high torque and high vertical loads on the front end of the machine. This includes front-mounted liquid tanks and front 3-point hitches.

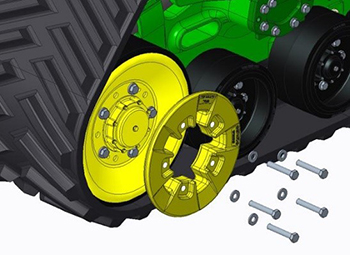

9RX Tractors

A front frame support kit is required on all 9RX Tractors with front-mounted liquid tanks or a front 3-point hitch. This kit enables operators to utilize the 9RX Tractors for supplemental crop nutrition application or for utilizing a rear 3-point hitch mounted sprayer. The front frame supports are standard on all 9RX Scraper Tractors.

Mounting of dozer blades

The mounting of dozer blades is approved on 9R and 9RX Tractors with 762-mm and 914-mm (30-in. and 36-in.) tracks. The mounting of dozer blades is not approved on 9RT and 9RX Tractors with 457-mm and 610-mm (18-in. and 24-in.) tracks.

- For all 9R and 9RX Tractors with 762-mm and 914-mm (30-in. and 36-in.) tracks, additional frame supports supplied by the dozer manufacturer are required.

- Follow manufacturer guidelines for mounting dozer blade components to the frame of the tractor.

Cab Operator's Station

Conjunto de suporte para tablet BRE10255 (1), conjunto de suporte para telefone celular BRE10015 (2) e suporte de montagem em forma de L RE343680 (3)

Conjunto de suporte para tablet BRE10255 (1), conjunto de suporte para telefone celular BRE10015 (2) e suporte de montagem em forma de L RE343680 (3)

Conjunto de porta-copos com autonivelamento BRE10152

Conjunto de porta-copos com autonivelamento BRE10152

Conjunto de suporte de telefone celular com bloqueio por sucção BXE10606

Conjunto de suporte de telefone celular com bloqueio por sucção BXE10606

Conjunto de suporte de tablet com bloqueio por sucção BXE10607

Conjunto de suporte de tablet com bloqueio por sucção BXE10607

Conjunto de suporte para tablet BRE10255

Conjunto de suporte para tablet BRE10255

Conjunto de suporte para tablet BXE10864

Conjunto de suporte para tablet BXE10864

O suporte para tablet, telefone celular ou bebidas pode ser feito facilmente com estas soluções. Estas soluções robustas e fáceis de usar mantêm todos os itens importantes exatamente onde são desejados.

Carpet floor mat

Carpet floor mat

Reduce cab noise and increase comfort with fabric flooring in the cab. This snag-resistant mat is color-matched to the existing tractor cab interior and is easily removed and installed for quick cleaning. The die-cut carpet lays directly over the rubber floor in the cab and is a precise fit. This feature is included in the Ultimate Comfort and Convenience package.

Conjunto de suporte para tablet BRE10255 (1), conjunto de suporte para telefone celular BRE10015 (2) e suporte de montagem em forma de L RE343680 (3)

Conjunto de suporte para tablet BRE10255 (1), conjunto de suporte para telefone celular BRE10015 (2) e suporte de montagem em forma de L RE343680 (3)

Conjunto de porta-copos com autonivelamento BRE10152

Conjunto de porta-copos com autonivelamento BRE10152

Conjunto de suporte de telefone celular com bloqueio por sucção BXE10606

Conjunto de suporte de telefone celular com bloqueio por sucção BXE10606

Conjunto de suporte de tablet com bloqueio por sucção BXE10607

Conjunto de suporte de tablet com bloqueio por sucção BXE10607

Conjunto de suporte para tablet BRE10255

Conjunto de suporte para tablet BRE10255

Conjunto de suporte para tablet BXE10864

Conjunto de suporte para tablet BXE10864

O suporte para tablet, telefone celular ou bebidas pode ser feito facilmente com estas soluções. Estas soluções robustas e fáceis de usar mantêm todos os itens importantes exatamente onde são desejados.

Display GreenStar™ 3 2630 exibido

Display GreenStar™ 3 2630 exibido

Use as tabelas abaixo para encontrar todas as peças necessárias para conectar os displays GreenStar™ fisicamente e eletronicamente.

Para displays GreenStar™ 2 2600 CommandCenter™/GreenStar™ 3 2630:

Tipo de montagem |

Suporte do display (esfera) |

Conjunto do tirante |

Suporte do trilho (esfera) |

Abraçadeira |

PF11019 mais dois 19M8648 |

RE574454 |

AXE59372 |

10 mm roscado |

PF11019 mais dois 19M8648 |

PF80459 |

RE576490 |

|

|||

Suporte de localização única |

RE558242 |

||

O suporte tipo abraçadeira com monitor GreenStar™ não é recomendado com o trilho vertical (BRE10575).

OBSERVAÇÃO: Encomende também o chicote elétrico (PF90686) e o cabo Ethernet (PFP12950). Também está disponível uma película protetora opcional para a tela (PF90596).

Para display universal 4240/4640 e monitor estendido:

Tipo de montagem |

Suporte do display (esfera) |

Conjunto do tirante |

Suporte do trilho (esfera) |

Abraçadeira |

AL212683 mais quatro 19M8648 |

AXE59372 |

|

10 mm roscado |

UC17356 mais quatro 19M8648 |

PF80459 |

RE576490 |

|

|||

Suporte de localização única |

RE558242 |

||

O suporte tipo abraçadeira com monitor GreenStar™ não é recomendado com o trilho vertical (BRE10575).

OBSERVAÇÃO: Encomende também o chicote elétrico (PFP12435) e o cabo Ethernet (RE573617). Também está disponível uma película protetora opcional para a tela (PF90596).

BRE10501 CommandARM bracket

BRE10501 CommandARM bracket

This unique bracket connects to the right side of the CommandARM. It is compatible with the cell phone mount (BRE10015), tablet mount (BRE10255), and more. It is also compatible with the touchscreen radio relocation kit (BXX11045) for Premium and Ultimate Comfort and Convenience packages.

Cup Holder Kit - 9340RWBXX10883

Fire Extinguisher, Wheel and 4 Track - 9340RWBRE10242

The floor insulation kit can reduce cab heat generated by transmission and hydraulic oil temperatures below the cab floor. It can reduce the overall cab temperature, as it works as a thermal barrier. The product comes in a large sheet, which is easily cut to fit the contours of the cab floor.

The kit is large enough to fit the floor pan design of 6 through 9 Series Tractor cabs.

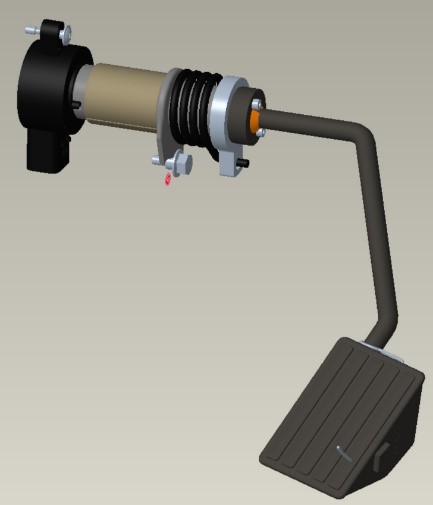

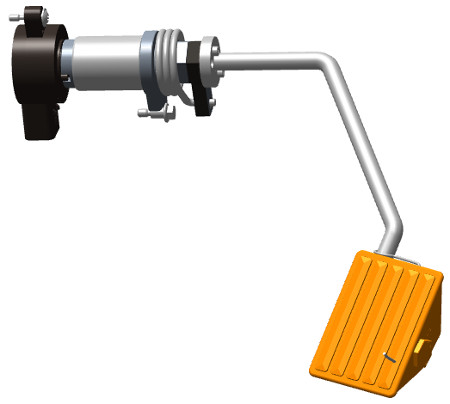

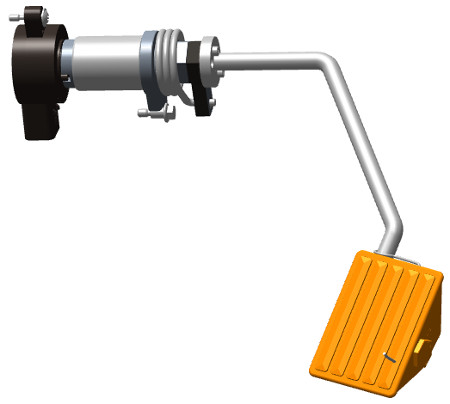

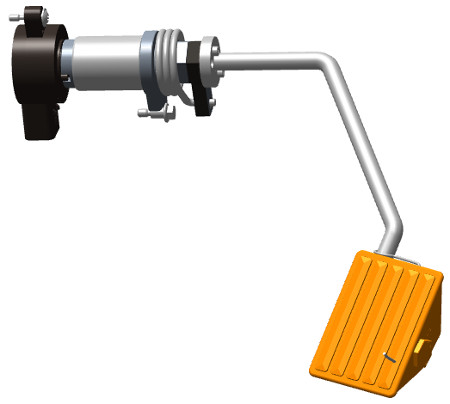

Foot decelerator next to pedals

Foot decelerator next to pedals

BXX10810 foot decelerator kit

BXX10810 foot decelerator kit

The foot decelerator kit adds the ability to decrease vehicle speed with the right foot. This allows the operator to progressively slow ground speed during precise maneuvering such as at headland turns or around objects without adjusting the set speed. This is exceptionally helpful when operating at full speed for long periods of time.

BRE10458 footrest kit with three pegs

BRE10458 footrest kit with three pegs

Foot peg on the steering column

Foot peg on the steering column

The steering column is designed to accept foot pegs, which are included in the Premium and Ultimate Comfort and Convenience packages. Producers with a Select cab can still easily add this feature.

The kit contains three pegs. Two front-facing pegs thread directly into the steering column. A third peg mounts near the right-side window and is used in combination with the right front peg when the operator seat is swiveled to the right. This upgrade is helpful when operating on steep downhill grades, sidehills, or watching towed implements.

Features:

- Direct bolt-on factory finish – no drilling or cutting required

- Heavy gauge steel to support any operator

- Color-matched rubber surfaces for comfort and vibration reduction

- Model year 2022 and newer are compatible with the extension and adjustment kit (BRE10511)

Foot-Operated Speed Control - 9340RWBXX10812

Headliner Mounting Rail - 9340RWR572009

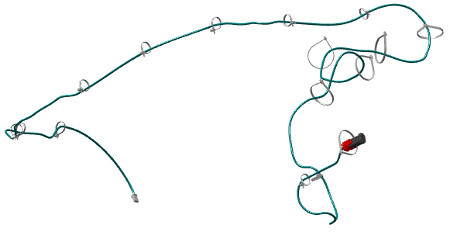

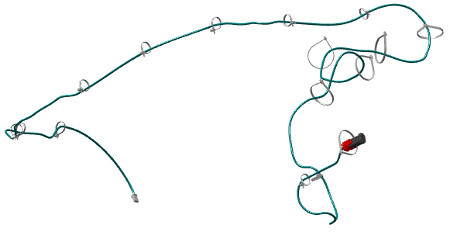

R562310 harness routing hook (shown mounted to headliner rail R558980 and using retention features of the C-post)

R562310 harness routing hook (shown mounted to headliner rail R558980 and using retention features of the C-post)

Harness routing hook

Harness routing hook

Keep accessory and monitor wiring neatly contained with these moveable harness hooks. These hooks are specifically designed to easily snap into the factory headliner rail and BRE10574 window mounting bracket and rail with no tools and can be moved as needed. These hooks allow accessory wiring to routed together for a clean look and maximized visibility.

RE584990 leather steering wheel

RE584990 leather steering wheel

Close-up of leather steering wheel

Close-up of leather steering wheel

Add a little comfort to the day with the leather-wrapped steering wheel. This upgrade is included with the Ultimate Comfort and Convenience package and can be added to the Select or Premium cab by reusing existing mounting hardware.

Conjunto de tirante AL212683 com placas de montagem

Conjunto de tirante AL212683 com placas de montagem

Conjunto de tirante de 117,6 mm PF80459

Conjunto de tirante de 117,6 mm PF80459

Suporte esférico de 38,1 mm PF80460 em parafuso em U

Suporte esférico de 38,1 mm PF80460 em parafuso em U

Conjunto de tirante de 76,2 mm RE574454 com esfera de 38,1 mm em placa de montagem redonda

Conjunto de tirante de 76,2 mm RE574454 com esfera de 38,1 mm em placa de montagem redonda

Suporte esférico de 38,1 mm UC17356 em quadrado universal

Suporte esférico de 38,1 mm UC17356 em quadrado universal

Suporte esférico de 25,4 mm RE558821 em viga de 10 mm

Suporte esférico de 25,4 mm RE558821 em viga de 10 mm

Suporte de montagem de acessórios tipo abraçadeira AXE59372

Suporte de montagem de acessórios tipo abraçadeira AXE59372

Conjunto de suporte esférico com ranhura em T de 25,4 mm (esquerda) BRE10482 e conjunto de suporte esférico com ranhura em T de 38,1 mm BRE10483

Conjunto de suporte esférico com ranhura em T de 25,4 mm (esquerda) BRE10482 e conjunto de suporte esférico com ranhura em T de 38,1 mm BRE10483

Há uma variedade de soluções adicionais de peças de montagem disponíveis na John Deere para resolver necessidades específicas de configuração de montagem. A tabela abaixo inclui várias peças adicionais (não mostradas acima) para ajudar em diversas necessidades de montagem.

Display GreenStar™ 3 2630 exibido

Display GreenStar™ 3 2630 exibido

Use as tabelas abaixo para encontrar todas as peças necessárias para conectar os displays GreenStar™ fisicamente e eletronicamente.

Para displays GreenStar™ 2 2600 CommandCenter™/GreenStar™ 3 2630:

Tipo de montagem |

Suporte do display (esfera) |

Conjunto do tirante |

Suporte do trilho (esfera) |

Abraçadeira |

PF11019 mais dois 19M8648 |

RE574454 |

AXE59372 |

10 mm roscado |

PF11019 mais dois 19M8648 |

PF80459 |

RE576490 |

|

|||

Suporte de localização única |

RE558242 |

||

O suporte tipo abraçadeira com monitor GreenStar™ não é recomendado com o trilho vertical (BRE10575).

OBSERVAÇÃO: Encomende também o chicote elétrico (PF90686) e o cabo Ethernet (PFP12950). Também está disponível uma película protetora opcional para a tela (PF90596).

Para display universal 4240/4640 e monitor estendido:

Tipo de montagem |

Suporte do display (esfera) |

Conjunto do tirante |

Suporte do trilho (esfera) |

Abraçadeira |

AL212683 mais quatro 19M8648 |

AXE59372 |

|

10 mm roscado |

UC17356 mais quatro 19M8648 |

PF80459 |

RE576490 |

|

|||

Suporte de localização única |

RE558242 |

||

O suporte tipo abraçadeira com monitor GreenStar™ não é recomendado com o trilho vertical (BRE10575).

OBSERVAÇÃO: Encomende também o chicote elétrico (PFP12435) e o cabo Ethernet (RE573617). Também está disponível uma película protetora opcional para a tela (PF90596).

Refrigerator

Refrigerator

Keep food and drinks cool with refrigerator

Keep food and drinks cool with refrigerator

The refrigerator unit can be added to a cab ordered with a Select Comfort and Convenience package by purchasing the three service parts used in the Premium and Ultimate Comfort and Convenience packages. The main refrigerator unit installs inside the storage compartment behind the instructional seat and requires a weather seal and plug to be added. All wiring already exists, and no software is required to complete the install.

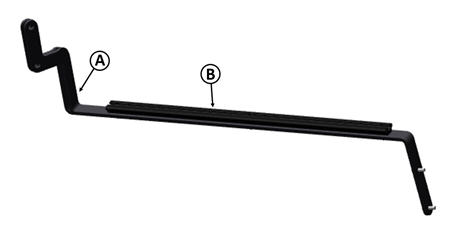

Conjunto BRE10574 com suporte de aço (A) e trilho de montagem (B)

Conjunto BRE10574 com suporte de aço (A) e trilho de montagem (B)

Um suporte de aço grande, que abrange toda a janela do lado direito, é montado diretamente na estrutura da cabine para maior rigidez e resistência. O trilho de montagem do revestimento (incluído neste kit) é aparafusado no suporte de aço. Esta solução permite ao operador configurar e reconfigurar monitores e acessórios sem alterar as soluções de montagem, a partir de qualquer dos dois locais. Esse trilho acomoda soluções de montagem de tipo abraçadeira e ranhura em T (adquiridas separadamente).

- Abrange a janela inteira do lado direito.

- Utiliza o mesmo número de peça do trilho de montagem do revestimento de fábrica (R558980) para fácil reconfiguração dos acessórios.

- O trilho de montagem de alumínio é montado na parte superior ou inferior do suporte de aço, permitindo ainda mais opções e maximizando as preferências de visibilidade.

- Compatível com AXE59372 (suporte tipo abraçadeira) e BRE10482 e BRE10483 (suportes esféricos com ranhura em T).

Secondary Hitch Controls - 9340RWBRE10437

Conjunto de suporte para tablet BRE10255 (1), conjunto de suporte para telefone celular BRE10015 (2) e suporte de montagem em forma de L RE343680 (3)

Conjunto de suporte para tablet BRE10255 (1), conjunto de suporte para telefone celular BRE10015 (2) e suporte de montagem em forma de L RE343680 (3)

Conjunto de porta-copos com autonivelamento BRE10152

Conjunto de porta-copos com autonivelamento BRE10152

Conjunto de suporte de telefone celular com bloqueio por sucção BXE10606

Conjunto de suporte de telefone celular com bloqueio por sucção BXE10606

Conjunto de suporte de tablet com bloqueio por sucção BXE10607

Conjunto de suporte de tablet com bloqueio por sucção BXE10607

Conjunto de suporte para tablet BRE10255

Conjunto de suporte para tablet BRE10255

Conjunto de suporte para tablet BXE10864

Conjunto de suporte para tablet BXE10864

O suporte para tablet, telefone celular ou bebidas pode ser feito facilmente com estas soluções. Estas soluções robustas e fáceis de usar mantêm todos os itens importantes exatamente onde são desejados.

Trilho vertical curto BRE10575 (montado no poste dianteiro direito)

Trilho vertical curto BRE10575 (montado no poste dianteiro direito)

Trilho vertical curto (montado no poste traseiro direito inferior)

Trilho vertical curto (montado no poste traseiro direito inferior)

Trilho vertical curto (montado no poste C traseiro esquerdo)

Trilho vertical curto (montado no poste C traseiro esquerdo)

Está disponível um trilho de montagem de alumínio mais curto, de 260 mm. O kit inclui todas as peças de fixação necessárias para montar em até cinco locais verticais, incluindo a estrutura de proteção na capotagem (EPC) do poste A direito superior e inferior, a EPC do poste C superior direito e a EPC do poste C superior traseiro esquerdo. É compatível com os suportes esféricos com abraçadeira e com ranhura em T (adquiridos separadamente).

- Até cinco locais verticais sustentados por este trilho (o kit contém um trilho e peças de fixação).

- Utiliza o mesmo formato de trilho de montagem do revestimento de fábrica para facilitar o ajuste e as preferências do operador.

- Funciona em combinação com outras soluções de suporte de acessórios.

- Compatível com AXE59372 (suporte tipo abraçadeira) e BRE10482 e BRE10483 (suportes esféricos com ranhura em T).

BRE10436 multifunction lever (shown in model year 2018 7R Tractor)

BRE10436 multifunction lever (shown in model year 2018 7R Tractor)

This optional cross-gate joystick (multifunction lever) replaces fingertip paddle pots for control of selective control valves (SCVs) and allows for programmable hydraulic functionality according to operator preference. It mounts directly to the CommandARM™ console. This is the same joystick (multifunction lever) that is included with a factory-ordered front-end loader.

StarFire 6000 Locking Bracket - 9340RWBPF11074

RE275532 storage container

RE275532 storage container

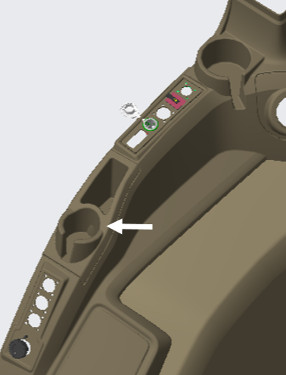

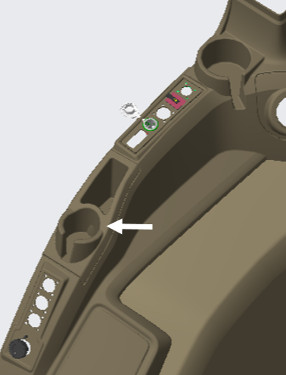

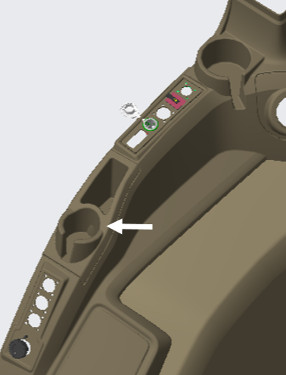

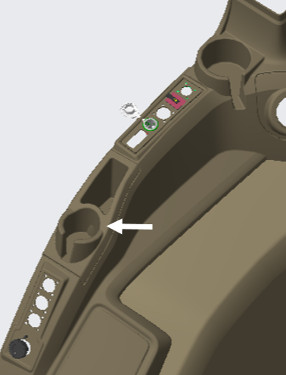

Storage container mounting location

Storage container mounting location

This storage container is a heavy plastic cup with a hinged lid and foam seal. It keeps ash, snacks, or small items well contained and fits snugly into the smaller cup holder in the upholstery (shown with arrow above) along the right-side window.

RE593670 sun shade shown

RE593670 sun shade shown

The cab uses the same sun shade part number in the front, right-side, and rear windows, which are included in the Premium and Ultimate Comfort and Convenience packages. Producers with a Select cab can easily add a sun shade or two.

Conjunto de suporte para tablet BRE10255 (1), conjunto de suporte para telefone celular BRE10015 (2) e suporte de montagem em forma de L RE343680 (3)

Conjunto de suporte para tablet BRE10255 (1), conjunto de suporte para telefone celular BRE10015 (2) e suporte de montagem em forma de L RE343680 (3)

Conjunto de porta-copos com autonivelamento BRE10152

Conjunto de porta-copos com autonivelamento BRE10152

Conjunto de suporte de telefone celular com bloqueio por sucção BXE10606

Conjunto de suporte de telefone celular com bloqueio por sucção BXE10606

Conjunto de suporte de tablet com bloqueio por sucção BXE10607

Conjunto de suporte de tablet com bloqueio por sucção BXE10607

Conjunto de suporte para tablet BRE10255

Conjunto de suporte para tablet BRE10255

Conjunto de suporte para tablet BXE10864

Conjunto de suporte para tablet BXE10864

O suporte para tablet, telefone celular ou bebidas pode ser feito facilmente com estas soluções. Estas soluções robustas e fáceis de usar mantêm todos os itens importantes exatamente onde são desejados.

R569171 door lock handle

R569171 door lock handle

Add a level of security with this custom door lock handle. This kit replaces the factory-installed handle with a lock cylinder that is different from the ignition start switch and includes two matched keys. Additional keys must be made at a local locksmith.

Connectivity Hardware

Front Implement CAN Communication Connector - 9340RWRE344751

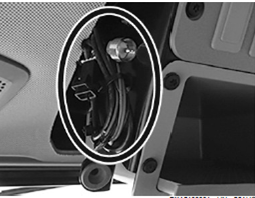

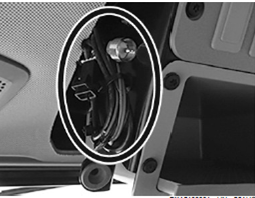

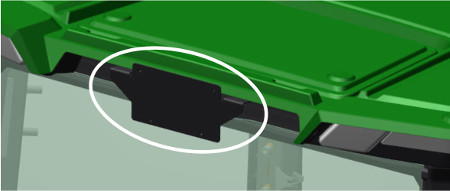

ISO 11783 location in model year 2011 to 2020 R Series Tractor cab

ISO 11783 location in model year 2011 to 2020 R Series Tractor cab

ISO 11783 location in model year 2020 7R and 8R/8RT/8RX (with updated cab) and model year 2022 and newer 9R/9RT/9RX

ISO 11783 location in model year 2020 7R and 8R/8RT/8RX (with updated cab) and model year 2022 and newer 9R/9RT/9RX

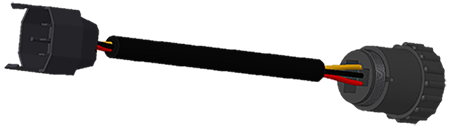

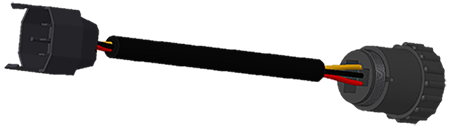

RE322780 ISO cab implement CAN bus adapter

RE322780 ISO cab implement CAN bus adapter

The ISO cab implement CAN bus adapter is available to connect any ISO compliant implement or device to an 8R, 8RT, 9R, 9RT, and 9RX (including Scraper Special) Tractor. These connectors are commonly used for planter frame control boxes.

Refer to the operator's manual, sections 16 (CommandCenter™) and 25 (Operator Station), for additional information on ISO implements.

NOTE: If the harness is not in use, unplug it from the ISO 11783 location or plug the four-pin connectors together on the harness. If neither of these are done, implement CAN communication errors occur.

StarFire mounting bracket

StarFire mounting bracket

The model year 2020 and newer large tractors (with updated cab) have a low-profile, offset StarFire receiver integrated into the roof shell. However, there is a mounting bracket solution to add a StarFire 3000 (with deluxe shroud) or StarFire 6000 Receiver. This bracket connects to the center of the front roof near the wiper motor for an exceptional fit with a clean look. The 12-pin wiring harness on both the StarFire 3000 and StarFire 6000 are compatible with the base cab electrical connector.

RTK Bracket Kit - 9340RWBRE10512

DISPLAY HARDWARE

Display Harness - GS2 / GS3 Display with Video to GreenStar™ (Round) Cornerpost 762 mm (30 in.) - 9340RWPFP12435

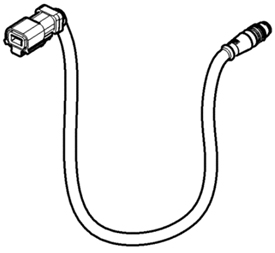

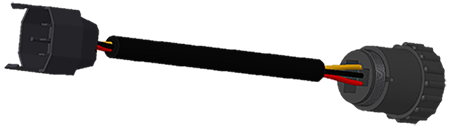

Ethernet cable

Ethernet cable

This cable connects the cornerpost Ethernet connector (square) to the GreenStar™ 3 2630 Display Ethernet connector (round). It is required for used with Remote Display Access (RDA), Wireless Data Transfer (WDT), and Machine Sync.

The square-to-round connector cable is 80-cm (31.5-in.) long.

Gen 4 and GreenStar™ Displays Bracket for Single Display - Tractor and Sprayer - 9340RWBPF12124

GreenStar™/Gen4 - 254 mm (10 in.) Display Touch Panel Protector Service Kit - 9340RWPF90596

Harness - Original GreenStar™ Display and Mobile Processor to GreenStar™ 3 or GreenStar™ 2 (Round) Cornerpost - 9340RWPF90686

Drawbar

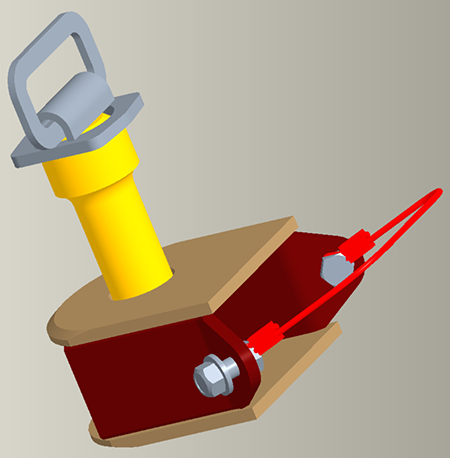

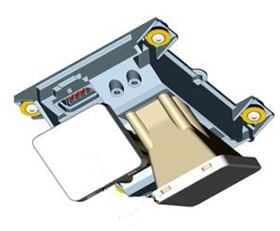

Hydraulic hose support

Hydraulic hose support

This field-installed option reduces stress on the couplers by providing support to the heavy hydraulic hoses used in scraper application. The hydraulic hose support attaches to the back of the tractor next to the drawbar.

Electrical

3-pin octagonal to 3-pin round convenience outlet (flat pins) single device adapter - 9340RWRE596959

NOTE: The information below is intended to show a more complete portfolio of options available for this area of the machine. Check the table below to verify specific model and configuration compatibility.

Carpet floor mat

Carpet floor mat

Reduce cab noise and increase comfort with fabric flooring in the cab. This snag-resistant mat is color-matched to the existing tractor cab interior and is easily removed and installed for quick cleaning. The die-cut carpet lays directly over the rubber floor in the cab and is a precise fit. This feature is included in the Ultimate Comfort and Convenience package.

Foot throttle next to pedals

Foot throttle next to pedals

BRE10440 foot throttle kit

BRE10440 foot throttle kit

The foot throttle kit adds the ability to control engine rpm with the right foot. This allows the operator to control ground speed like an automobile while driving or to make power adjustments to adjust hydraulic flow for operating certain implements.

Foot decelerator next to pedals

Foot decelerator next to pedals

BXX10810 foot decelerator kit

BXX10810 foot decelerator kit

The foot decelerator kit adds the ability to decrease vehicle speed with the right foot. This allows the operator to progressively slow ground speed during precise maneuvering such as at headland turns or around objects without adjusting the set speed. This is exceptionally helpful when operating at full speed for long periods of time.

BRE10458 footrest kit with three pegs

BRE10458 footrest kit with three pegs

Foot peg on the steering column

Foot peg on the steering column

The steering column is designed to accept foot pegs, which are included in the Premium and Ultimate Comfort and Convenience packages. Producers with a Select cab can still easily add this feature.

The kit contains three pegs. Two front-facing pegs thread directly into the steering column. A third peg mounts near the right-side window and is used in combination with the right front peg when the operator seat is swiveled to the right. This upgrade is helpful when operating on steep downhill grades, sidehills, or watching towed implements.

Features:

- Direct bolt-on factory finish – no drilling or cutting required

- Heavy gauge steel to support any operator

- Color-matched rubber surfaces for comfort and vibration reduction

- Model year 2022 and newer are compatible with extension and adjustment kit (BRE10511)

RE593670 sun shade shown

RE593670 sun shade shown

The cab uses the same sun shade part number in the front, right-side, and rear windows, which are included in the Premium and Ultimate Comfort and Convenience packages. Producers with a Select cab can easily add a sun shade or two.

Storage container with lid/ashtray

RE275532 storage container

RE275532 storage container

Storage container mounting location

Storage container mounting location

This storage container is a heavy plastic cup with a hinged lid and foam seal. It keeps ash, snacks, or small items well contained and fits snugly into the smaller cup holder in the upholstery (shown with arrow above) along the right side window.

Leather-wrapped steering wheel

RE584990 leather steering wheel

RE584990 leather steering wheel

Close-up of leather steering wheel

Close-up of leather steering wheel

Add a little comfort to the day with the leather-wrapped steering wheel. This upgrade is included with the Ultimate Comfort and Convenience package and can be added to the Select or Premium cab by reusing existing mounting hardware.

Refrigerator

Refrigerator

Keep food and drinks cool with refrigerator

Keep food and drinks cool with refrigerator

The refrigerator unit can be added to a cab ordered with a Select Comfort and Convenience package by purchasing the three service parts used in the Premium and Ultimate Comfort and Convenience packages. The main refrigerator unit installs inside the storage compartment behind the instructional seat and requires a weather seal and plug to be added. All wiring already exists and no software is required to complete the install.

RE588734 internal rear mirror (shown in standard mounting position)

RE588734 internal rear mirror (shown in standard mounting position)

The tractor comes equipped with a right side internally mounted rearview mirror. For added visibility and convenience, a second mirror can be added to the left side of the cab. This is exceptionally helpful for watching specific implements or jobs better viewed from the left side.

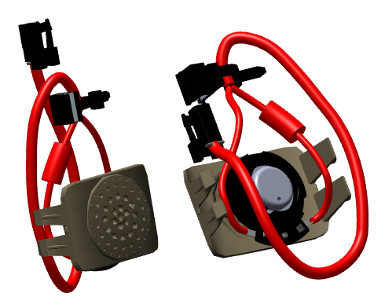

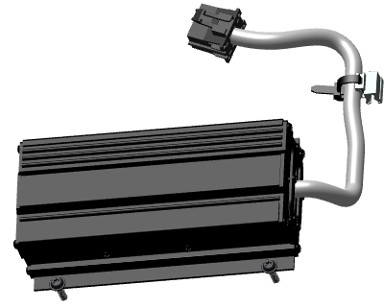

Type A/B style socket inverter kit (type C style is similar)

Type A/B style socket inverter kit (type C style is similar)

Cab power inverter kit

Cab power inverter kit

These kits include an inverter module, wiring harness, and interior color-matched receptacle. The mounting location is at the left C-post interior above the storage compartment or refrigerator unit. This inverter allows an operator to utilize household powered items such as a laptop or power tool charger. The receptacle kits are specific for either type B (compatible with type A and B plugs) or type C style socket (compatible with type C plugs). An interior, color-matched, self-closing cover is included to keep the socket clean from debris when not in use. This same feature is found in Premium and Ultimate Comfort and Convenience packages. Software is not necessary for this update.

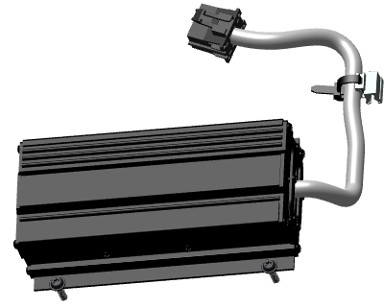

Six-outlet octagonal power strip with pre-installed round convenience outlet (flat pins)

RE596958 complete John Deere power strip for model year 2020 and newer cabs

RE596958 complete John Deere power strip for model year 2020 and newer cabs

The six-outlet octagonal power strip with pre-installed round convenience outlet is available for field installation for operators that prefer this traditional connection style. This solution can support up to 30 amps of power from the existing, shared 30-amp fused power circuit of the cab. It also provides operators with the same connection in the cab to power equipment they may already have or share with other machines over several generations. The above image shows one mounting option using vertical rail kit BRE10464.

Three-pin octagonal to three-pin round convenience outlet (flat pins) single device adapter

RE596959 power adapter

RE596959 power adapter

For operators who prefer the six-way power strip connection type but only have one or two accessories to connect in the cab, this single adapter solution is available. The single jumper harness converts one prewired three-pin octagonal style connector into a three-pin round outlet. This solution allows a more economically priced conversion for producers who do not need the full power strip solution.

A similar design for European power connector style is available as RE596960 three-pin octagonal to three-pin round/triangular convenience outlet (round pins) single device adapter.

Harness adapter for citizen band (CB) power connection

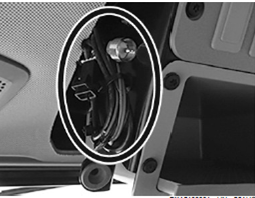

Antenna coax and power connector base prewired in the cab

Antenna coax and power connector base prewired in the cab

Harness adapter for power connection

Harness adapter for power connection

Operators using business band/citizen band (CB) radio in their cab will find the model year 2020 7R and 8R Tractors come prewired with antenna coax, power connector, and an NMO antenna base. When wiring the business band radio, the pig-tail connector can be hard wired to the constant power, switched power, and ground wires. It can then be connected directly to the cab base harness power connection point without any cutting or modification, eliminating any need to run new power wires from the fuse panel. These connection points are located under the upper right console next to the open storage tray and mirror/wiper controls, making for a clean install in the cab. The operator only needs to supply the radio unit and NMO style antenna of their choice.

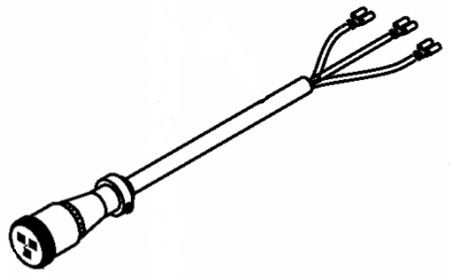

Amp-to-flying leads power connector

RE37651 power connector

RE37651 power connector

This adapter allows users to connect aftermarket displays to the universal amp power connector. The female three-socket connector has three flying leads that can be fused to the display harness. Once installed, the display harness will connect to the three-prong amp power adapter in the cab or to the RE67015 outlet adapter.

Amp-to-John Deere power outlet adapter

RE67015 outlet adapter

RE67015 outlet adapter

This adapter allows users to connect an amp-style, three-socket connector to the John Deere-style power strip connection type. Use this adapter to quickly and easily connect amp-style power accessories to older, vintage tractors that do not have an amp-style outlet already in the cab without cutting wire harnesses. This adapter can be kept connected into the John Deere-style power strip if users are regularly moving a unique display between vintage and newer tractors in the fleet.

External StarFire™ mounting bracket

StarFire mounting bracket

StarFire mounting bracket

The model year 2020 large tractors (with updated cab) have a low-profile, offset StarFire receiver integrated into the roof shell. However, there is a mounting bracket solution to add a StarFire 3000 (with deluxe shroud) or Starfire 6000 Receiver. This bracket connects to the center of the front roof near the wiper motor for an exceptional fit with a clean look. The 12-pin wiring harness on both the StarFire 3000 and StarFire 6000 are compatible with the base cab electrical connector.

Front license plate mounting bracket

License plate mounting bracket (front)

License plate mounting bracket (front)

This bracket solution provides a mounting location for countries that require a roadway license mounted to the front of the vehicle. This bracket bolts into place above the front window wiper motor and is also compatible with the external StarFire mounting bracket.

Vandal protection door locks with custom key

R569171 door lock handle

R569171 door lock handle

Add a level of security with this custom door lock handle. This kit replaces the factory-installed handle with a lock cylinder that is different from the ignition start switch and includes two matched keys. Additional keys must be made at a local locksmith.

Joystick (multifunction lever)

BRE10436 multifunction lever (shown in model year 2018 7R Tractor)

BRE10436 multifunction lever (shown in model year 2018 7R Tractor)

This optional cross-gate joystick (multifunction lever) replaces fingertip paddle pots for control of selective control valves (SCVs) and allows for programmable hydraulic functionality according to operator preference. It mounts directly to the CommandARM™ console. This is the same joystick (multifunction lever) that is included with a factory-ordered front-end loader.

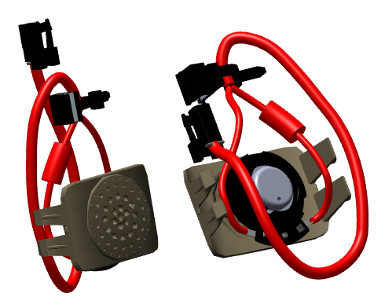

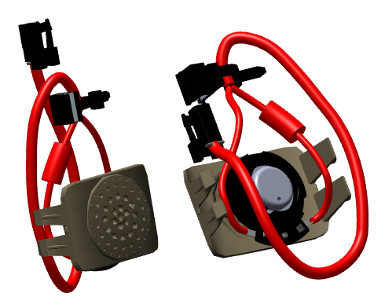

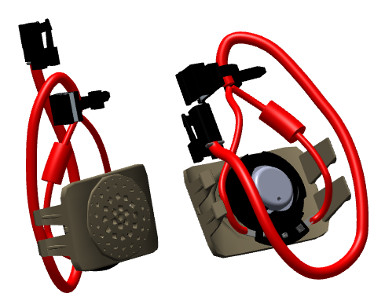

Subwoofer

Subwoofer

Tweeters

Tweeters

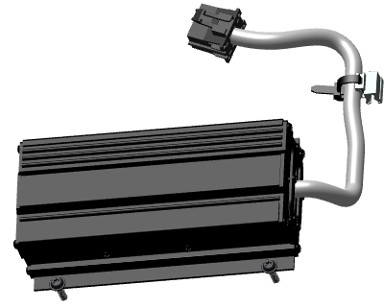

Amplifier

Amplifier

Add deep lows and bright high notes to the cab with this sound kit for the Select cab package radios (single DIN radio style). These components are the same factory-installed speakers that come with the touchscreen radio in the Premium and Ultimate cab packages, but are bundled together in this convenient kit for a Delphi radio.

The subwoofer is mounted under the operator seat, tweeters are added into the front windshield cab frame (after removing the existing plastic inserts), and an amplifier is positioned under the headliner. The entire kit plugs into the existing cab harness and does not need software to activate.

Touchscreen radio relocation kit

BXX11045 touchscreen radio relocation kit

BXX11045 touchscreen radio relocation kit

Move the touchscreen radio from the factory-installed location (upper right radio bezel) to several other locations with this relocation kit. The kit includes a new headliner bezel, brackets, harness jumper, hardware, and instructions to move the touchscreen unit from its factory location. This kit is for relocation mounting only and does not include the radio unit.

Features:

- Allows touchscreen radio to be mounted on rollover protective structure (ROPS) and off the CommandARM bracket or on several other accessory mounting bracket rails sold separately

- Fine-tune the position adjustment with the locking knob on the tie rod

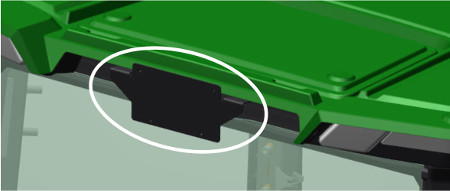

Touchscreen video camera upgrade kit

Touchscreen video camera upgrade kit

Touchscreen video camera upgrade kit

Add video capability to the touchscreen radio by adding this cable (video camera purchased separately). When installed, this cable connection port will be located on the outside of the rear cab next to the factory-installed video connection ports used with the Gen 4 display.

NOTE: Reference the Cab Mounting Solutions sales guide to view the wide range of mounting accessories for the cab.

NOTE: The information below is intended to show a more complete portfolio of options available for this area of the machine. Check the table below to verify specific model and configuration compatibility.

Carpet floor mat

Carpet floor mat

Reduce cab noise and increase comfort with fabric flooring in the cab. This snag-resistant mat is color-matched to the existing tractor cab interior and is easily removed and installed for quick cleaning. The die-cut carpet lays directly over the rubber floor in the cab and is a precise fit. This feature is included in the Ultimate Comfort and Convenience package.

Foot throttle next to pedals

Foot throttle next to pedals

BRE10440 foot throttle kit

BRE10440 foot throttle kit

The foot throttle kit adds the ability to control engine rpm with the right foot. This allows the operator to control ground speed like an automobile while driving or to make power adjustments to adjust hydraulic flow for operating certain implements.

Foot decelerator next to pedals

Foot decelerator next to pedals

BXX10810 foot decelerator kit

BXX10810 foot decelerator kit

The foot decelerator kit adds the ability to decrease vehicle speed with the right foot. This allows the operator to progressively slow ground speed during precise maneuvering such as at headland turns or around objects without adjusting the set speed. This is exceptionally helpful when operating at full speed for long periods of time.

BRE10458 footrest kit with three pegs

BRE10458 footrest kit with three pegs

Foot peg on the steering column

Foot peg on the steering column

The steering column is designed to accept foot pegs, which are included in the Premium and Ultimate Comfort and Convenience packages. Producers with a Select cab can still easily add this feature.

The kit contains three pegs. Two front-facing pegs thread directly into the steering column. A third peg mounts near the right-side window and is used in combination with the right front peg when the operator seat is swiveled to the right. This upgrade is helpful when operating on steep downhill grades, sidehills, or watching towed implements.

Features:

- Direct bolt-on factory finish – no drilling or cutting required

- Heavy gauge steel to support any operator

- Color-matched rubber surfaces for comfort and vibration reduction

- Model year 2022 and newer are compatible with extension and adjustment kit (BRE10511)

RE593670 sun shade shown

RE593670 sun shade shown

The cab uses the same sun shade part number in the front, right-side, and rear windows, which are included in the Premium and Ultimate Comfort and Convenience packages. Producers with a Select cab can easily add a sun shade or two.

Storage container with lid/ashtray

RE275532 storage container

RE275532 storage container

Storage container mounting location

Storage container mounting location

This storage container is a heavy plastic cup with a hinged lid and foam seal. It keeps ash, snacks, or small items well contained and fits snugly into the smaller cup holder in the upholstery (shown with arrow above) along the right side window.

Leather-wrapped steering wheel

RE584990 leather steering wheel

RE584990 leather steering wheel

Close-up of leather steering wheel

Close-up of leather steering wheel

Add a little comfort to the day with the leather-wrapped steering wheel. This upgrade is included with the Ultimate Comfort and Convenience package and can be added to the Select or Premium cab by reusing existing mounting hardware.

Refrigerator

Refrigerator

Keep food and drinks cool with refrigerator

Keep food and drinks cool with refrigerator

The refrigerator unit can be added to a cab ordered with a Select Comfort and Convenience package by purchasing the three service parts used in the Premium and Ultimate Comfort and Convenience packages. The main refrigerator unit installs inside the storage compartment behind the instructional seat and requires a weather seal and plug to be added. All wiring already exists and no software is required to complete the install.

RE588734 internal rear mirror (shown in standard mounting position)

RE588734 internal rear mirror (shown in standard mounting position)

The tractor comes equipped with a right side internally mounted rearview mirror. For added visibility and convenience, a second mirror can be added to the left side of the cab. This is exceptionally helpful for watching specific implements or jobs better viewed from the left side.

Type A/B style socket inverter kit (type C style is similar)

Type A/B style socket inverter kit (type C style is similar)

Cab power inverter kit

Cab power inverter kit

These kits include an inverter module, wiring harness, and interior color-matched receptacle. The mounting location is at the left C-post interior above the storage compartment or refrigerator unit. This inverter allows an operator to utilize household powered items such as a laptop or power tool charger. The receptacle kits are specific for either type B (compatible with type A and B plugs) or type C style socket (compatible with type C plugs). An interior, color-matched, self-closing cover is included to keep the socket clean from debris when not in use. This same feature is found in Premium and Ultimate Comfort and Convenience packages. Software is not necessary for this update.

Six-outlet octagonal power strip with pre-installed round convenience outlet (flat pins)

RE596958 complete John Deere power strip for model year 2020 and newer cabs

RE596958 complete John Deere power strip for model year 2020 and newer cabs

The six-outlet octagonal power strip with pre-installed round convenience outlet is available for field installation for operators that prefer this traditional connection style. This solution can support up to 30 amps of power from the existing, shared 30-amp fused power circuit of the cab. It also provides operators with the same connection in the cab to power equipment they may already have or share with other machines over several generations. The above image shows one mounting option using vertical rail kit BRE10464.

Three-pin octagonal to three-pin round convenience outlet (flat pins) single device adapter

RE596959 power adapter

RE596959 power adapter

For operators who prefer the six-way power strip connection type but only have one or two accessories to connect in the cab, this single adapter solution is available. The single jumper harness converts one prewired three-pin octagonal style connector into a three-pin round outlet. This solution allows a more economically priced conversion for producers who do not need the full power strip solution.

A similar design for European power connector style is available as RE596960 three-pin octagonal to three-pin round/triangular convenience outlet (round pins) single device adapter.

Harness adapter for citizen band (CB) power connection

Antenna coax and power connector base prewired in the cab

Antenna coax and power connector base prewired in the cab

Harness adapter for power connection

Harness adapter for power connection

Operators using business band/citizen band (CB) radio in their cab will find the model year 2020 7R and 8R Tractors come prewired with antenna coax, power connector, and an NMO antenna base. When wiring the business band radio, the pig-tail connector can be hard wired to the constant power, switched power, and ground wires. It can then be connected directly to the cab base harness power connection point without any cutting or modification, eliminating any need to run new power wires from the fuse panel. These connection points are located under the upper right console next to the open storage tray and mirror/wiper controls, making for a clean install in the cab. The operator only needs to supply the radio unit and NMO style antenna of their choice.

Amp-to-flying leads power connector

RE37651 power connector

RE37651 power connector

This adapter allows users to connect aftermarket displays to the universal amp power connector. The female three-socket connector has three flying leads that can be fused to the display harness. Once installed, the display harness will connect to the three-prong amp power adapter in the cab or to the RE67015 outlet adapter.

Amp-to-John Deere power outlet adapter

RE67015 outlet adapter

RE67015 outlet adapter

This adapter allows users to connect an amp-style, three-socket connector to the John Deere-style power strip connection type. Use this adapter to quickly and easily connect amp-style power accessories to older, vintage tractors that do not have an amp-style outlet already in the cab without cutting wire harnesses. This adapter can be kept connected into the John Deere-style power strip if users are regularly moving a unique display between vintage and newer tractors in the fleet.

External StarFire™ mounting bracket

StarFire mounting bracket

StarFire mounting bracket

The model year 2020 large tractors (with updated cab) have a low-profile, offset StarFire receiver integrated into the roof shell. However, there is a mounting bracket solution to add a StarFire 3000 (with deluxe shroud) or Starfire 6000 Receiver. This bracket connects to the center of the front roof near the wiper motor for an exceptional fit with a clean look. The 12-pin wiring harness on both the StarFire 3000 and StarFire 6000 are compatible with the base cab electrical connector.

Front license plate mounting bracket

License plate mounting bracket (front)

License plate mounting bracket (front)

This bracket solution provides a mounting location for countries that require a roadway license mounted to the front of the vehicle. This bracket bolts into place above the front window wiper motor and is also compatible with the external StarFire mounting bracket.

Vandal protection door locks with custom key

R569171 door lock handle

R569171 door lock handle

Add a level of security with this custom door lock handle. This kit replaces the factory-installed handle with a lock cylinder that is different from the ignition start switch and includes two matched keys. Additional keys must be made at a local locksmith.

Joystick (multifunction lever)

BRE10436 multifunction lever (shown in model year 2018 7R Tractor)

BRE10436 multifunction lever (shown in model year 2018 7R Tractor)

This optional cross-gate joystick (multifunction lever) replaces fingertip paddle pots for control of selective control valves (SCVs) and allows for programmable hydraulic functionality according to operator preference. It mounts directly to the CommandARM™ console. This is the same joystick (multifunction lever) that is included with a factory-ordered front-end loader.

Subwoofer

Subwoofer

Tweeters

Tweeters

Amplifier

Amplifier

Add deep lows and bright high notes to the cab with this sound kit for the Select cab package radios (single DIN radio style). These components are the same factory-installed speakers that come with the touchscreen radio in the Premium and Ultimate cab packages, but are bundled together in this convenient kit for a Delphi radio.

The subwoofer is mounted under the operator seat, tweeters are added into the front windshield cab frame (after removing the existing plastic inserts), and an amplifier is positioned under the headliner. The entire kit plugs into the existing cab harness and does not need software to activate.

Touchscreen radio relocation kit

BXX11045 touchscreen radio relocation kit

BXX11045 touchscreen radio relocation kit

Move the touchscreen radio from the factory-installed location (upper right radio bezel) to several other locations with this relocation kit. The kit includes a new headliner bezel, brackets, harness jumper, hardware, and instructions to move the touchscreen unit from its factory location. This kit is for relocation mounting only and does not include the radio unit.

Features:

- Allows touchscreen radio to be mounted on rollover protective structure (ROPS) and off the CommandARM bracket or on several other accessory mounting bracket rails sold separately

- Fine-tune the position adjustment with the locking knob on the tie rod

Touchscreen video camera upgrade kit

Touchscreen video camera upgrade kit

Touchscreen video camera upgrade kit

Add video capability to the touchscreen radio by adding this cable (video camera purchased separately). When installed, this cable connection port will be located on the outside of the rear cab next to the factory-installed video connection ports used with the Gen 4 display.

NOTE: Reference the Cab Mounting Solutions sales guide to view the wide range of mounting accessories for the cab.

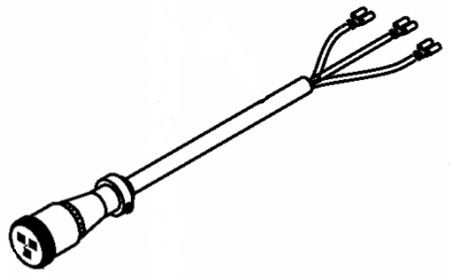

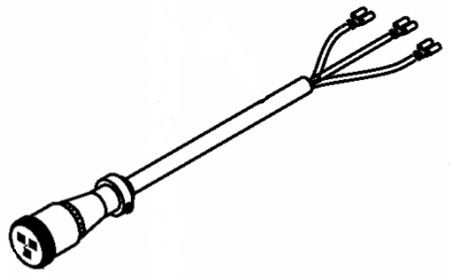

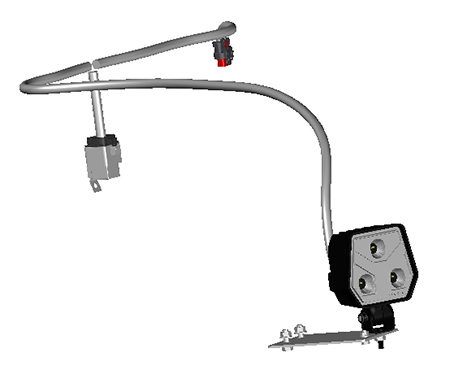

9-pin electrical connector

9-pin electrical connector

The nine-pin electrical connector is required to allow TouchSet depth control to be used on implements with this feature. The harness provides a position input to the tractor selective control valve (SCV) unit that enables the TouchSet system.

This feature allows the operator to adjust height and depth of remote lift cylinders by using the TouchSet controls in the cab.

Type A/B style socket inverter kit (type C style is similar)

Type A/B style socket inverter kit (type C style is similar)

Cab power inverter kit

Cab power inverter kit

These kits include an inverter module, wiring harness, and interior color-matched receptacle. The mounting location is at the left C-post interior above the storage compartment or refrigerator unit. This inverter allows an operator to utilize household powered items such as a laptop or power tool charger. The receptacle kits are specific for either type B (compatible with type A and B plugs) or type C style socket (compatible with type C plugs). An interior, color-matched, self-closing cover is included to keep the socket clean from debris when not in use. This same feature is found in Premium and Ultimate Comfort and Convenience packages. Software is not necessary for this update.

NOTE: The information below is intended to show a more complete portfolio of options available for this area of the machine. Check the table below to verify specific model and configuration compatibility.

Carpet floor mat

Carpet floor mat

Reduce cab noise and increase comfort with fabric flooring in the cab. This snag-resistant mat is color-matched to the existing tractor cab interior and is easily removed and installed for quick cleaning. The die-cut carpet lays directly over the rubber floor in the cab and is a precise fit. This feature is included in the Ultimate Comfort and Convenience package.

Foot throttle next to pedals

Foot throttle next to pedals

BRE10440 foot throttle kit

BRE10440 foot throttle kit

The foot throttle kit adds the ability to control engine rpm with the right foot. This allows the operator to control ground speed like an automobile while driving or to make power adjustments to adjust hydraulic flow for operating certain implements.

Foot decelerator next to pedals

Foot decelerator next to pedals

BXX10810 foot decelerator kit

BXX10810 foot decelerator kit

The foot decelerator kit adds the ability to decrease vehicle speed with the right foot. This allows the operator to progressively slow ground speed during precise maneuvering such as at headland turns or around objects without adjusting the set speed. This is exceptionally helpful when operating at full speed for long periods of time.

BRE10458 footrest kit with three pegs

BRE10458 footrest kit with three pegs

Foot peg on the steering column

Foot peg on the steering column

The steering column is designed to accept foot pegs, which are included in the Premium and Ultimate Comfort and Convenience packages. Producers with a Select cab can still easily add this feature.

The kit contains three pegs. Two front-facing pegs thread directly into the steering column. A third peg mounts near the right-side window and is used in combination with the right front peg when the operator seat is swiveled to the right. This upgrade is helpful when operating on steep downhill grades, sidehills, or watching towed implements.

Features:

- Direct bolt-on factory finish – no drilling or cutting required

- Heavy gauge steel to support any operator

- Color-matched rubber surfaces for comfort and vibration reduction

- Model year 2022 and newer are compatible with extension and adjustment kit (BRE10511)

RE593670 sun shade shown

RE593670 sun shade shown

The cab uses the same sun shade part number in the front, right-side, and rear windows, which are included in the Premium and Ultimate Comfort and Convenience packages. Producers with a Select cab can easily add a sun shade or two.

Storage container with lid/ashtray

RE275532 storage container

RE275532 storage container

Storage container mounting location

Storage container mounting location

This storage container is a heavy plastic cup with a hinged lid and foam seal. It keeps ash, snacks, or small items well contained and fits snugly into the smaller cup holder in the upholstery (shown with arrow above) along the right side window.

Leather-wrapped steering wheel

RE584990 leather steering wheel

RE584990 leather steering wheel

Close-up of leather steering wheel

Close-up of leather steering wheel

Add a little comfort to the day with the leather-wrapped steering wheel. This upgrade is included with the Ultimate Comfort and Convenience package and can be added to the Select or Premium cab by reusing existing mounting hardware.

Refrigerator

Refrigerator

Keep food and drinks cool with refrigerator

Keep food and drinks cool with refrigerator

The refrigerator unit can be added to a cab ordered with a Select Comfort and Convenience package by purchasing the three service parts used in the Premium and Ultimate Comfort and Convenience packages. The main refrigerator unit installs inside the storage compartment behind the instructional seat and requires a weather seal and plug to be added. All wiring already exists and no software is required to complete the install.

RE588734 internal rear mirror (shown in standard mounting position)

RE588734 internal rear mirror (shown in standard mounting position)

The tractor comes equipped with a right side internally mounted rearview mirror. For added visibility and convenience, a second mirror can be added to the left side of the cab. This is exceptionally helpful for watching specific implements or jobs better viewed from the left side.

Type A/B style socket inverter kit (type C style is similar)

Type A/B style socket inverter kit (type C style is similar)

Cab power inverter kit

Cab power inverter kit

These kits include an inverter module, wiring harness, and interior color-matched receptacle. The mounting location is at the left C-post interior above the storage compartment or refrigerator unit. This inverter allows an operator to utilize household powered items such as a laptop or power tool charger. The receptacle kits are specific for either type B (compatible with type A and B plugs) or type C style socket (compatible with type C plugs). An interior, color-matched, self-closing cover is included to keep the socket clean from debris when not in use. This same feature is found in Premium and Ultimate Comfort and Convenience packages. Software is not necessary for this update.

Six-outlet octagonal power strip with pre-installed round convenience outlet (flat pins)

RE596958 complete John Deere power strip for model year 2020 and newer cabs

RE596958 complete John Deere power strip for model year 2020 and newer cabs

The six-outlet octagonal power strip with pre-installed round convenience outlet is available for field installation for operators that prefer this traditional connection style. This solution can support up to 30 amps of power from the existing, shared 30-amp fused power circuit of the cab. It also provides operators with the same connection in the cab to power equipment they may already have or share with other machines over several generations. The above image shows one mounting option using vertical rail kit BRE10464.

Three-pin octagonal to three-pin round convenience outlet (flat pins) single device adapter

RE596959 power adapter

RE596959 power adapter

For operators who prefer the six-way power strip connection type but only have one or two accessories to connect in the cab, this single adapter solution is available. The single jumper harness converts one prewired three-pin octagonal style connector into a three-pin round outlet. This solution allows a more economically priced conversion for producers who do not need the full power strip solution.

A similar design for European power connector style is available as RE596960 three-pin octagonal to three-pin round/triangular convenience outlet (round pins) single device adapter.

Harness adapter for citizen band (CB) power connection

Antenna coax and power connector base prewired in the cab

Antenna coax and power connector base prewired in the cab

Harness adapter for power connection

Harness adapter for power connection