1550 TERRAINCUT MOWER

TerrainCut™ Front Mower

front-mowers

- 7-Iron™ PRO Side Discharge or Fastback™ Rear Discharge Deck

- Diesel Engine

- Biodiesel Conversion Kit available

- Compatible with select front blade, snow blower and broom attachments

Apply For FinancingMaintenance Plans

View Product Brochure

60 Day Promise

Features

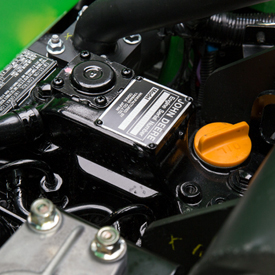

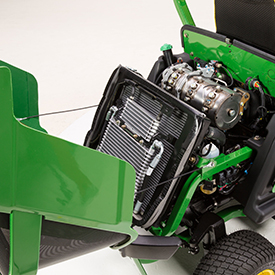

Diesel engine has high-quality features to minimize operating cost

Hood open for access to engine

Hood open for access to engine

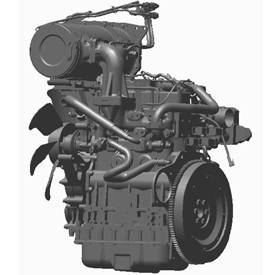

3-cylinder, liquid-cooled diesel engine

3-cylinder, liquid-cooled diesel engine

The 1500 Series TerrainCut™ Front Mowers are powered by liquid-cooled, 3-cylinder diesel engines.

These engines feature low levels of exhaust and emissions, reduced noise levels, and excellent fuel economy. They also meet the necessary Environmental Protection Agency (EPA) Tier 4 emissions requirements.

The 1570, 1575, 1580, and 1585 models are biodiesel compatible from the factory up to B20. The 1550 model requires an optional kit to be compatible with B20 biodiesel fuel.

Engine drawing for 1570, 1575, 1580, and 1585

Engine drawing for 1570, 1575, 1580, and 1585

| 1550 | 1570, 1575, 1580, 1585 | |

| Fuel | Diesel (optional kit permits B20 compatibility) | Diesel (B20 compatible) |

| Gross power at maximum rpm | 25 hp (18.4 kW), PS | 37.4 hp (27.5 kW), PS |

| Displacement | 77 cu in. (1.262 L) | 100.2 cu in. (1.642 L) |

Key features of the engine include:

- Economical cast-in block cylinder design for good cooling and long life

- Indirect fuel injection (1550)

- Direct fuel injection (1570, 1575, 1580, 1585)

- Injects fuel directly on top of pistons for more efficient combustion

- Delivers more horsepower per gallon of fuel

- Improves starting

- Develops more horsepower per gallon of fuel and improves starting

- Aluminum alloy pistons with built-in steel struts are lightweight to reduce connection rod bearing loads and provide good heat transfer characteristics

- Design permits tighter tolerances and neutralizes expansion of the piston, thereby reducing blow-by gas and noise from the piston slap

- Higher top rings on the piston and a thinner head gasket greatly reduce the volume of unburned waste gases and increase combustion efficiency

- Timing gears and injector drive gears utilize helical profile gears to help lower engine noise; gear teeth have a newly designed roll-off profile, giving almost no clash, no noise, and no backlash

- Fuel filter with replaceable element

- Full-pressure intake manifold provides quick starts in temperatures down to 0°F (-18°C) (optional engine coolant heater attachment assists starting under more extreme conditions)

- Auto-bleed fuel system – there is no need to prime the system if the tractor runs out of fuel; the system self-primes the injection pump, lines, and injectors, providing fast fuel recovery

- Key start and shutoff eliminates fuel shut-off knob; electric solenoid shuts fuel supply off immediately when key is turned off

- See-through coolant recovery tank permits operator to check coolant level without removing radiator cap

- Enclosed engine compartment to keep out debris and lower sound levels

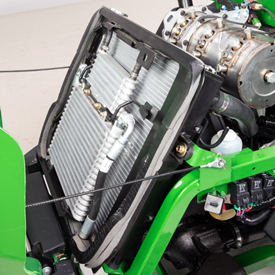

- Sealed radiator compartment to keep trash and debris on outside of hood

- Excellent torque for plenty of lugging power when operating in tough mowing conditions

- Full-pressure lubrication for positive lubrication, even when operating on slopes

- Dual-element, dry-type, replaceable air cleaner completely sealed for effective cleaning

- 90 percent to 95 percent of dirt ejected before it reaches the paper element

- Secondary safety element for additional filtering

- Progressive-type air restriction indicator to let operator know when the filter needs servicing

- Automotive-type alternator for plenty of charge to the battery and power for accessories

- 75 amp for open-station models

- 95 amp for ComfortCab models

- Automatic initiation of air heater for easier cold-weather starting

- Automotive-sensing system tells operator when engine is ready to start

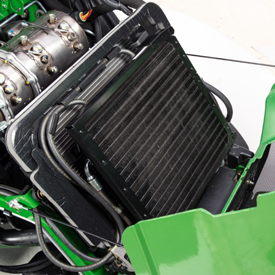

Rear-mounted radiators

Rear-mounted radiators (1550, 1570, 1580)

Rear-mounted radiators (1550, 1570, 1580)

Rear-mounted radiators and air conditioner condenser (1575, 1585)

Rear-mounted radiators and air conditioner condenser (1575, 1585)

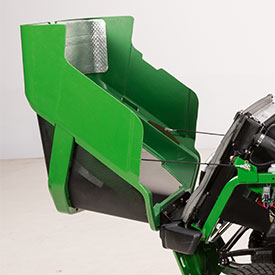

Fuel tank is large capacity with convenient gauge for maximum uptime

Fuel tank

Fuel tank

Fuel gauge (shown on 1585)

Fuel gauge (shown on 1585)

Fuel tank features:

- 16-U.S. gal. (60.6-L) capacity provides a 10-hour run time.

- Top draw provides clean fuel.

- Fuel indicator is conveniently located.

Mower decks for TerrainCut™ Front Mowers match a wide variety of needs

Since 1998 the John Deere 7-Iron™ mower deck has demonstrated commercial quality, performance, and durability. The 7-Iron PRO, FastBack™, and FastBack PRO mower decks deliver an even higher-quality cut in even more diverse conditions.

1580 TerrainCut Front Mower with 72-in. (183-cm) FastBack PRO Mower Deck

1580 TerrainCut Front Mower with 72-in. (183-cm) FastBack PRO Mower Deck

1575 TerrainCut Front Mower with 72-in. (183-cm) 7-Iron PRO Mower Deck

1575 TerrainCut Front Mower with 72-in. (183-cm) 7-Iron PRO Mower Deck

TerrainCut Front Mower Compatibility

| Mower Deck | 1550 | 1570 | 1575 | 1580 | 1585 |

| 60-in. (152-cm) 7-Iron PRO Side-Discharge Mower Deck | X | X | X* | X* | X* |

| 62-in. (157-cm) FastBack Rear-Discharge Mower Deck | X | X | X | X | X |

| 72-in. (183-cm) 7-Iron PRO Side-Discharge Mower Deck | X | X | X | X | X |

| 72-in. (183-cm) FastBack PRO Rear-Discharge Mower Deck | X | X | X | X | X |

Rear weights (UC13263) are required based on machine configuration. Must also order TCB10303, rear weight mounting bracket.

*Mower deck offset for trimming capability. Vehicle track width is 2 in. (5.1 cm) wider on the discharge side of deck. This may cause the tire to drive over uncut grass on discharge side of deck.

NOTE: These mower decks will not retrofit to F900 Series or F1145 Front Mowers.

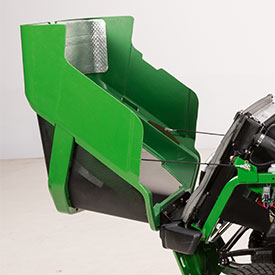

Rotate for Service (RFS™)

Mower deck showing RFS feature

Mower deck showing RFS feature

Rotate for Service (RFS) feature provides access for cleaning and maintenance of the mower decks:

-

The rotation angle will vary depending on deck size and power unit tire size.

-

No tools are required to access belts.

-

The underside of the mower deck is easy to access.

-

Easy on/off design simplifies installing and removing mower decks.

-

Top, greaseable spindles can be accessed without removing belt covers.

The Rotate for Service position also reduces the length of the machine for trailering.

Certification

TerrainCut Front Mowers comply with ANSI B71.4 safety certification.

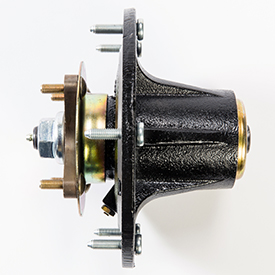

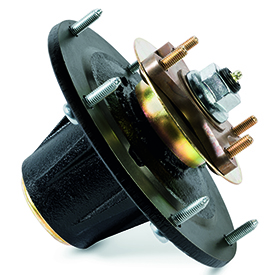

Heavy-duty blade spindles

Cast-iron spindle housing

Cast-iron spindle housing

Cast-iron spindle housing

Cast-iron spindle housing

The mower spindle housings are made of ductile cast iron.

Key benefits of ductile cast-iron spindle housings:

- Ductile cast-iron material provides superior impact strength.

- Gusseted design puts reinforcement where it is needed.

- Strength of cast iron protects against damage from blade impacts.

- Grease fitting is mounted at the top for easy access.

- Grease pressure-relief valve minimizes seal damage from overfilling with grease and keeps debris from entering housing.

- The 8-in. (20.3-cm) diameter housing distributes loads and impacts to minimize deck-shell damage.

- Spindle allows ability to be rebuilt.

NOTE: The 72-in. (183-cm) 7-Iron V-Flex Side-Discharge Mower Deck has an aluminum center spindle housing. The outside blades are driven by cast-iron gearboxes.

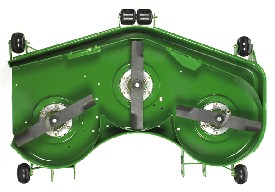

60-in. (152-cm) 7-Iron PRO Side-Discharge Mower Deck

60-in. 7-Iron PRO Mower Deck

60-in. 7-Iron PRO Mower Deck

60-in. 7-Iron PRO Mower Deck

60-in. 7-Iron PRO Mower Deck

Features include:

- Blade tip speed of 18,000 fpm (5486 m/min) for more blade strikes per inch mowed.

- Trim-edge bumper reduces damage to the mower deck and property.

- Redesigned front baffle manages airflow and controls clippings better.

- Blade spindle housings are made of ductile cast iron

- Gusseted design puts reinforcement where it is needed.

- Spindle pocket reinforcement gives even greater structural durability.

- Adjustable anti-scalp wheels help smooth out the mowing job.

- Standard semi-pneumatic caster tires will not go flat from punctures.

The mower is designed to provide exceptional cut quality at higher travel speeds:

- The mower deck is stamped from 7-gauge, 0.179-in. (4.6-mm) steel to minimize the number of welds and provide a smooth underside, with fewer sharp corners, for reduced material buildup.

- Provides precision components and long deck life

- Single piece of steel means no welds to break

- Provides a smooth underside, without corners, reducing material buildup

- 0.75-in. (1.9-cm) solid steel bar is welded to mower deck perimeter for added strength.

- The rounded corners of the stamped deck help distribute impact stress to reduce the potential of damage when the mower contacts trees, rocks, curbs, and other fixed obstacles.

- A deep-deck design of 5.5-in. (14-cm) delivers excellent airflow so material can be processed quickly and efficiently.

- 1-in. to 6-in. (2.5-cm to 12.7-cm) cutting heights, in 0.5-in. (1.3-cm) increments, allow the operator to match all mowing conditions.

Unique baffling system allows grass to stand up before being cut, producing a uniform length and appearance:

- Baffling system eliminates clumping, blowout, and windrowing.

- Wide discharge opening provides even clipping dispersal for an excellent, finished appearance in all conditions.

62-in. (157-cm) FastBack Mower Deck

62-in. FastBack Mower Deck

62-in. FastBack Mower Deck

The 62-in. (157-cm) FastBack rear-discharge mower is ideally suited for:

- Areas where people are present

- Schools

- Parks

- Playgrounds

- Traffic areas (city boulevards, roadsides, etc.)

- Conditions and applications:

- Areas with long grass and weeds

- Areas where customer is not as concerned about having a wide dispersal of grass (park areas, roadsides, etc.)

- Government bids that specify a rear discharge mower.

Key features of the 62-in. (157-cm) Rear-Discharge Mower Deck include:

- Mower deck is constructed of 7-gauge, 0.179-in. (4.6-mm) steel for the strength to stand up to the demanding use of commercial and municipal mowing applications.

- Blade spindle housings are made of ductile cast iron.

- Gusseted design puts reinforcement where it is needed.

- Deck is constructed with a unique baffling system that reduces clumping and windrowing and produces a finished appearance that competitive rear-discharge mowers cannot match.

- The belt-drive system has an easy-to-adjust tension device.

- By using a spring system, the risk for over tensioning is eliminated, ensuring a long belt life and excellent performance during the season.

- For easy service and maintenance, the deck can be rotated into the vertical locked service position.

- Deep-deck design increases airflow so more material can be processed.

- Operator can trim with either side.

- Dual side trimming increases operator productivity.

- 1-in. to 6-in. (2.5-cm to 15.2-cm) cutting heights, in 0.5-in. (1.3-cm) increments, allow the operator to match all mowing conditions.

-

Gauge wheels, rollers, or side-mounted skid shoes lift the deck over uneven surfaces for a well-groomed appearance.

-

Double-captured anti-scalp wheels provide increased durability.

-

Easy lift and lock system for service purposes.

-

Standard semi-pneumatic caster tires will not go flat when punctured.

-

Spindles can be greased without removing belt shields.

-

1-in. (2.5-cm) cold-forged spindles are strong for long life.

-

Heat-treated to provide additional strength

-

-

Certified to European (CE) standards

72-in. (152-cm) 7-Iron PRO Side-Discharge Mower Deck

72-in. 7-Iron Pro Side-Discharge Mower Deck

72-in. 7-Iron Pro Side-Discharge Mower Deck

Features include:

- Blade tip speed of 18,000 fpm (5486 m/min) for more blade strikes per inch mowed.

- Trim-edge bumper reduces damage to the mower deck and property.

- Redesigned front baffle manages airflow and controls clippings better.

- Spindle pocket reinforcement gives even greater structural durability.

- Blade spindle housings are made of ductile cast iron.

- Gusseted design puts reinforcement where it is needed.

- Adjustable anti-scalp wheels help smooth out the mowing job.

- Standard semi-pneumatic caster tires will not go flat from punctures.

The mower is designed to provide exceptional cut quality at higher travel speeds:

- The mower deck is stamped from 7-gague, 0.179-in. (4.6-mm) steel to minimize the number of welds and provide a smooth underside, with fewer sharp corners, for reduced material buildup.

- Provides precision components and long deck life

- Single piece of steel means no welds to break

- Provides a smooth underside, without corners, reducing material buildup

- 0.75-in. (1.9-cm) solid steel bar is welded to mower deck perimeter for added strength.

- The rounded corners of the stamped deck help distribute impact stress to reduce the potential of damage when the mower contacts trees, rocks, curbs, and other fixed obstacles.

- A deep-deck design of 5.5-in. (14-cm) delivers excellent airflow so material can be processed quickly and efficiently.

- 1-in. to 6-in. (2.5-cm to 12.7-cm) cutting heights, in 0.5-in. (1.3-cm) increments, allow the operator to match all mowing conditions.

Unique baffling system allows grass to stand up before being cut, producing a uniform length and appearance:

- Baffling system eliminates clumping, blowout, and windrowing.

- Wide discharge opening provides even clipping dispersal for an excellent, finished appearance in all conditions.

72-in. (183-cm) FastBack PRO Mower Deck

72-in. FastBack PRO Mower Deck

72-in. FastBack PRO Mower Deck

The 72-in. (183-cm) Rear-Discharge FastBack PRO Mower Deck is ideally for professional landscapers and government municipalities requiring rear discharge placement of grass and debris, John Deere FastBack PRO rear-discharge mower decks deliver a commercial mowing solution. Advantages of a rear-discharge mower include:

- Less chance of damage from objects being thrown from the mower deck

- Time savings with the ability to mow closely around fixed objects with either side of the deck

- A cleaner mowing experience by lessening the amount of debris that can blow onto the operator

A rear-discharge mower deck is ideally suited for:

- Schools

- Parks

- Playgrounds

- Traffic areas (city boulevards, roadsides, etc.)

- Areas with long, grassy spots that need to be cut, where you are not as concerned about wide dispersal of grass (park areas, roadsides, etc.)

- Some government bids specify that the mower is equipped with a rear discharge.

Key features of the 72-in. (183-cm) Rear-Discharge Mower Deck include:

- Mower deck is constructed of 7-gauge, 0.179-in. (4.6-mm) steel for the strength to stand up to the demanding use of commercial and municipal mowing applications.

- Blade spindle housings are made of ductile cast iron.

- Gusseted design puts reinforcement where it is needed.

- Deck is constructed with a unique baffling system that reduces clumping and windrowing and produces a finished appearance that competitive rear-discharge mowers cannot match.

- Operator can trim with either side.

- Dual side trimming increases operator productivity.

- Trim-edge bumpers on each side reduces damage to the mower deck and property.

- The belt-drive system has an easy-to-adjust tension device.

- By using a spring system, the risk for over tensioning is eliminated, ensuring a long belt life and excellent performance during the season.

- For easy service and maintenance, the deck can be rotated into the vertical locked service position. Deep-deck design increases airflow so more material can be processed.

- 1-in. to 6-in. (2.5-cm to 15.2-cm) cutting heights, in 0.5-in. (1.3-cm) increments, allow the operator to match all mowing conditions.

- Gauge wheels or rollers lift the deck over uneven surfaces for a well-groomed appearance.

- Double-captured anti-scalp wheels provide increased durability. Easy lift and lock system for service purposes.

- Standard semi-pneumatic caster tires will not go flat when punctured. Spindles can be greased without removing belt shields.

- 1-in. (2.5-cm) cold-forged spindles are strong for long life.

- Heat-treated to provide additional strength

- Certified to European (CE) standards

Mower deck specifications

|

60-in. (152-cm) 7- Iron PRO Side- Discharge |

62-in. (157-cm) FastBack Rear- Discharge |

72-in. (183-cm) 7- Iron PRO Side- Discharge |

72-in. (183-cm) FastBack PRO Rear- Discharge |

Gauge (thickness) |

7 gauge, 0.179 in. (4.6 mm) |

7 gauge, 0.179 in. (4.6 mm) |

7 gauge, 0.179 in. (4.6 mm) |

7 gauge, 0.179 in. (4.6 mm) |

Cutting height |

1 to 6 in. (2.5 to 15.2 cm) |

1 to 6 in. (2.5 to 15.2 cm) |

1 to 6 in. (2.5 to 15.2 cm) |

1 to 6 in. (2.5 to 15.2 cm) |

Caster wheel type |

Semi-pneumatic |

Semi-pneumatic |

Semi-pneumatic |

Semi-pneumatic |

Gauge wheels |

Yes, front and rear |

Yes, front and rear |

Yes, front and rear |

Yes, front and rear |

Deck oscillation relative to ground plane |

+/- 15 degrees |

+/- 15 degrees |

+/- 15 degrees |

+/- 15 degrees |

Lateral deck tilt |

+/- 8 degrees |

+/- 8 degrees |

+/- 8 degrees |

+/- 8 degrees |

Deck installed at factory |

No |

No |

No |

No |

Time required for one person to install or remove deck (without tools) |

10 minutes |

10 minutes |

10 minutes |

10 minutes |

Time to change height of cut |

3 minutes without tools |

3 minutes without tools |

3 minutes without tools |

3 minutes without tools |

Belt type |

Kevlar belt |

Kevlar belt |

Kevlar belt |

Kevlar belt |

Belt shield type |

Plastic |

Plastic |

Plastic |

Plastic |

Belt shield time to remove or install |

2 minutes or less |

2 minutes or less |

2 minutes or less |

2 minutes or less |

Blade type |

High lift |

Medium lift |

High lift |

Medium lift |

Blade tip speed |

18,000 fpm (5,486 m/min) |

16,000 fpm (4,877 m/min) |

18,000 fpm (5,486 m/min) |

18,000 fpm ( 5,486 m/min) |

Spindles |

3 |

3 |

3 |

3 |

Spindle-housing material |

Ductile cast iron |

Ductile cast iron |

Ductile cast iron |

Ductile cast iron |

Deck level laterally when raised |

Yes |

Yes |

Yes |

Yes |

Discharge |

Side |

Rear |

Side |

Rear |

Mowing width |

60 in. (152 cm) |

62 in. (157 cm) |

72 in. (183 cm) |

72 in. (183 cm) |

Overall width (chute down) |

74 in. (188 cm) |

64 in. (163 cm) |

86 in. (218 cm) |

74 in. (188 cm) |

Weight |

--- |

--- |

--- |

--- |

PTO shaft drive is easy to access for quick-change of equipment

Front mower PTO shaft drive

Front mower PTO shaft drive

Live, independent power take-off (PTO) powers a mower deck, rotary broom, or two-stage snow blower:

- PTO can be engaged or disengaged on the go for greater productivity.

- Hydraulic PTO clutch has delay relief valve for soft engagement.

- Wet clutch design provides long life.

- PTO is easily accessible.

Tires are matched to the machine size and mower widths

1550, 1570, 1575 tires

Tires

Tires

Standard drive tires:

- 23x10.5-12 or 23x8.5-12 (1550, 1570)

- 23x10.5-12 (1575)

Available steering tires: 18x8.5-10 (4WD) or 18x8.5-8 (2WD)

1580, 1585 tires

Standard drive tires: 26x12-12, 6 PR drive tires (1580, 1585)

Standard steering tires: 20x10.00-10, 6 PR steering tires (1580, 1585)

Optional mulching kits add versatility to the mower decks

Typical mulch kit shown

Typical mulch kit shown

Kits are available to convert the 60-in. (152-cm) and 72-in. (183-cm) 7-Iron™ PRO Side-Discharge Mower Decks into mulching decks for use in grass and leaves.

The mulch kits include mulching blades, baffles, end covers, and attaching hardware.

Easy-to-operate controls maximize productivity

1570 TerrainCut™ Front Mower

1570 TerrainCut™ Front Mower

1585 TerrainCut Front Mower

1585 TerrainCut Front Mower

Maneuverability:

- Turn radius of 13 in. (33 cm)

- Uncut circle of 28 in. (71.1 cm) with a 72-in. (183-cm) 7-Iron™ PRO mower deck

- Deck offset and pulled rearward

- Tail-follows-the-trail trimming capability with 72-in. (183-cm) side-discharge mower deck

- Steered wheels (tail) stay within the path (trail) cut by the mower deck, allowing maneuverability without the rear of the machine contacting mowing obstacles

Operator controls (1570 shown)

Operator controls (1570 shown)

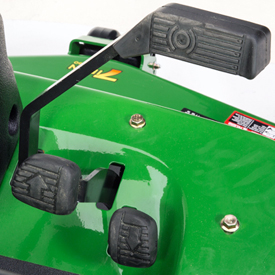

Master stop brake/directional foot pedals

Master stop brake/directional foot pedals

Hydrostatic power steering provides the following benefits:

- Makes it easy to turn the unit for less operator fatigue

- Allows quick turns - two turns lock to lock - for excellent productivity

The steering console offers the following:

- Throttle

- Key switch

- Headlight switch

- T4 display for monitoring performance (1570, 1575, 1580, 1585)

Transmission controls, range lever, and on-demand four-wheel drive (4WD) lever (1585 shown)

Transmission controls, range lever, and on-demand four-wheel drive (4WD) lever (1585 shown)

Controls including levers for double-spool auxiliary hydraulic kit (1585 shown)

Controls including levers for double-spool auxiliary hydraulic kit (1585 shown)

Console information/warning lights include the following:

- Hour meter

- Battery discharge light

- Engine oil pressure

- Engine coolant temperature

- Hydraulic oil over temperature

- Air preheater

- Lights

- Power take-off (PTO) operation indication

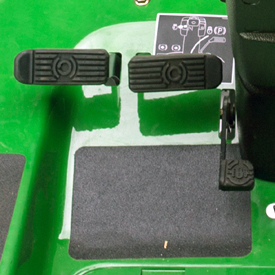

Two-pedal foot control

Two-pedal foot control

Two-pedal foot control:

- Allows the operator to select speed and direction with just the touch of a toe

- Keeps both hands free for steering and operating controls

Master stop brake (parking brake):

- Provides stopping power to both drive wheels

- Disengages the power take-off (PTO)

- Disengages the optional cruise control

- Used also for a parking brake

Individual turn-assist brakes and differential lock

Individual turn-assist brakes and differential lock

Individual turn-assist brakes:

- Provides additional traction when operating on hillsides

- Ideal for tight trimming situations

- Works in conjunction with hydrostatic foot controls to stop or slow the unit for turns

Differential lock:

- Locks both front drive wheels together for added traction

- Easily engaged with the left foot

4WD lever (1570 shown)

4WD lever (1570 shown)

Deck lift-control lever

Deck lift-control lever

The 4WD control lever is standard on 1575, 1580, and 1585; it is a factory-installed option on the 1550 and 1570.

The 4WD control lever:

- Allows the operator to select between on-demand or full-time 4WD on 1550, 1570, and 1575 models

- Allows the operator to select between on-demand or full-time 4WD and full-time two-wheel drive (2WD) on 1580 and 1585 models

Electronic cruise control (optional):

- Beneficial when mowing open areas or when transporting

The lift-control lever is conveniently located within easy reach of the operator's right hand.

1585 shown with control levers for double-spool auxiliary hydraulic kit

1585 shown with control levers for double-spool auxiliary hydraulic kit

A two-speed transaxle shift lever is standard on 1580 and 1585.

Safety starting system helps protect the operator and others

1550 mowing grass

1550 mowing grass

TerrainCut™ Front Mowers have an operator-presence system.

To start the engine the following conditions must be met:

- Master brake must be depressed or the parking brake locked; the hydrostatic foot controls will then be in the neutral position.

- PTO must be disengaged

- Ignition key must be used.

In addition, once the engine is running, an interlock automatically shuts the engine and PTO off if the operator leaves the seat. To keep the engine running, the operator must disengage the PTO and set the parking brake before dismounting.

Tilt steering and headlights are standard equipment

Three-piece steering column

Three-piece steering column

The three-piece steering column provides the following:

- Easy access to the steering valve and electrical components

- Better fit-up and appearance

- Easy adjustment to accommodate all operators

- Standard 50-W halogen headlights

Tilt steering

Tilt steering column (1550 shown)

Tilt steering column (1550 shown)

Tilt steering column allows the operator to adjust to the most comfortable position:

- Allows additional clearance for platform entry and exit

- Over 15 in. (38.1 cm) of travel

- Works in conjunction with the seat to accommodate all operators, regardless of size

Certification ensures compliance with safety standards

Rollover protective structure (ROPS)

Rollover protective structure (ROPS)

TerrainCut Front Mowers comply with ANSI B71.4 2004 safety certification specification.

The ROPS complies with the U.S. Occupational Safety and Health Administration (OSHA) 1928.51 standard for rollover protection.

Brakes and differential lock are convenient to use for maximum productivity

Wet-disk brakes/differential lock

Wet-disk brakes/differential lock

Wet-disk brakes are standard equipment:

- Provide positive stopping power and long life

- Require minimal adjustment

- Individual turn brakes are located on left side of platform

The differential lock is also included as standard equipment:

- Locks both front drive wheels together for extra traction, when needed

- Conveniently located pedal to allow the operator to engage the differential lock with the left foot while maintaining speed and direction (forward or reverse) with the right foot

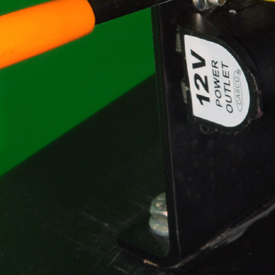

12-V power outlet is convenient to use

12-V power outlet

12-V power outlet

The 12-V power outlet can be used to recharge radios and cell phones, popular tools used by commercial cutters.

The outlet is conveniently located under the front of the seat.

Front mower seats have standard suspension with arm rests for added comfort and productivity

Standard comfort-adjust suspension seat

Standard comfort-adjust suspension seat

Optional air-ride suspension seat

Optional air-ride suspension seat

Operator comfort enhances productivity. TerrainCut™ Front Mowers include suspension seats with green accents and an embroidered John Deere logo. The comfort-adjust mechanical spring suspension seat is base equipment, and an air-ride suspension is an optional upgrade. The operator can adjust suspension by increasing or decreasing pressure for optimum comfort. Fore-aft adjustments accommodate both tall and short operators.

Both seats are 24-in. (61-cm) tall and include back-angle, lumbar, and arm rest adjustments. The eye-catching seats are constructed from two unique vinyl textures and sewn with decorative stitching. Retractable seat belts prevent belts from becoming tangled in the seat suspension and controls.

Other comfort features include:

- Standard cup holder

- Noise level meets North American and European standards

Serviceability is designed-in to reduce maintenance cost and increase uptime

Engine hood

Large screened area of engine hood

Large screened area of engine hood

Hood latch

Hood latch

Engine hood includes large screened area:

- Minimizes the amount of material that can get to the cooling radiators

- Minimizes the need to clean the hood screens

Hood latch keeps the hood securely in place, providing an optimum seal:

- A single hood latch is located on top of the hood behind the seat.

Engine hood opens to the rear

Engine hood opens to the rear

Designed-in service accessibility

Designed-in service accessibility

Designed-in service accessibility helps ensure daily maintenance is completed to keep the machine operating at peak performance.

The hood opens rearward, exposing the following:

- Engine

- Oil and fuel filter

- Hydraulic oil cooler

- Radiator check/fill

The hood can be totally removed, if necessary. The seat flips forward for access to air filter, fuse bank, engine oil dipstick, and front of engine.

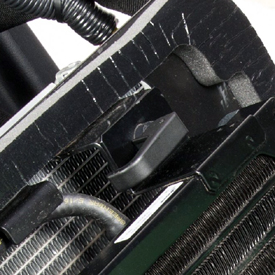

Condenser release knob

Condenser release knob

Condenser tilted back to permit cleaning

Condenser tilted back to permit cleaning

Easy-to-turn knobs are provided to release the air conditioning condenser (1575 and 1585 only) and fuel and hydraulic oil coolers so they can be tilted back to permit thorough cleaning between them and the engine coolant radiator.

Quick response (QR) codes link to owner information web pages

QR code label on control console

QR code label on control console

To speed access to owner information web pages, a QR code is printed onto a product identification number (PIN) label located on the control console near the seat. The owner information web pages that include links to:

- Safety and how-to videos

- Operator’s manuals

- Parts catalogs

- Maintenance reminder sheets

- Attachments

- Warranty statements

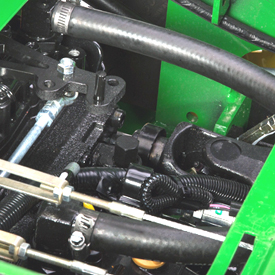

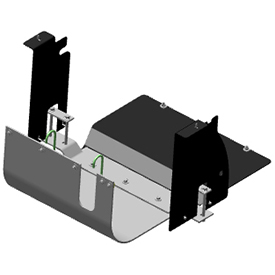

Foot platform access panel

Removable foot platform

Removable foot platform

The panel on the foot platform can be removed for access to the transaxle, PTO shaft, and most linkages.

Easy-to-read daily service decal is located on the bottom of the foot platform panel:

- Provides access to easily hook up driveshaft when changing implements

- Makes it more likely service will be performed at the optimum time, thus ensuring the highest level of performance and uptime

Panel on foot platform removed

Panel on foot platform removed

Removal of the foot platform gives convenient access to the driveshaft that powers the mower deck, snow blower and rotary broom:

- Helps make changing from one front implement to another easier and more convenient

Hydraulic hoses have reusable O-ring seal (ORS) fittings:

- ORS fittings seal at a lower torque to prevent leaks.

- Fittings can be removed from a damaged hose and installed on another hose.

- Downtime and cost for repairs are reduced considerably.

Rotate For Service™ (RFS) feature shown

Rotate For Service™ (RFS) feature shown

RFS service lockout latch

RFS service lockout latch

RFS feature provides access for cleaning and maintenance of the mower decks:

- The service-latch pin allows mower deck to lock into position to ensure deck is held in position for cleaning or service.

- The top-greaseable spindle grease fittings can be accessed without removing the belt covers.

Trailering features are included to reduce the time and cost to move equipment

Trailering features are designed-in for convenience:

- Designed-in trailer tie-downs are located at the front and rear of the machine.

- 26-degree deck lift will clear the steepest trailer ramps for easy loading and unloading.

- Rotate For Service™ (RFS) decks take up less room when transporting on trailers, allowing more room for other important equipment.

Remote battery posts

Remote battery posts

Remote battery posts

Remote battery posts simplify jump starting. Both positive and negative posts are located in front of the right rear steer tire.

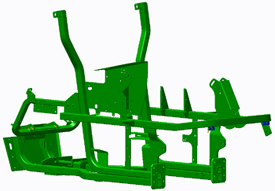

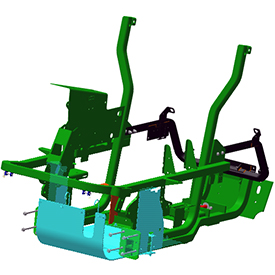

Welded frame structure is made of high-strength steel

High-strength, tubular steel frame

High-strength, tubular steel frame

The revolutionary tubular, high-strength welded steel frame provides durability and allows major components to be located lower in the machine:

-

The design results in a lower center of gravity for better stability and traction on hillsides and slopes.

-

Rollover protective structures (ROPS) are integral members of the frame.

Durable design

Durability features of the frame include:

- Heat-treated cast-iron axles with 1.24-in. (3.15-cm) kingpins

- Internal wet-disk brakes

- Hydraulic PTO clutch, with brake

- Provides smooth engagement and long life

- Hydrostatic oil cooler

- O-ring seal (ORS) hydraulic fittings

- Integrated, shaft-driven power take-off (PTO)

- Sealed relays and electrical connectors

- Heavy-duty, dual hydraulic cylinders

- Nodular cast-iron lift arm sockets

- Cast-iron rear bumper

Hydrostatic transmission and transaxle are heavy-duty to maximize uptime

Kanzaki 30-cc transmission

Kanzaki 30-cc transmission

A Kanzaki® 30-cc transmission is used for reliable operation.

Durability features include the following:

- High-capacity hydrostatic transmission and heavy-duty transaxle maximize performance and uptime and minimize cost of maintenance.

- Charge pump is used to efficiently deliver oil to the transmission.

- Oil cooler helps maintain optimum transmission oil temperature for superior performance and longer transmission life in the most challenging operating conditions.

- Maximum forward top speed is 12 mph (19.3 km/h) on the 1550, 1570, and 1575 and 15 mph (24.1 km/h) on the 1580 and 1585.

- Self-bleeding design helps keep air out of the system.

Kanzaki is a trademark of Kanzaki Kokyukoki Manufacturing Company.

Two-function mechanical rear-wheel drive for optimum use of the four-wheel drive feature

Mechanical rear-wheel drive axle

Mechanical rear-wheel drive axle

Mechanical rear-wheel drive is available as standard equipment (1575, 1580, 1585) or as a factory-installed option (1550, 1570):

- On-demand four-wheel drive automatically engages and disengages as needed.

- Constantly maximizes trimming ability

- Offers better fuel economy than full-time four-wheel drive

- Provides better steering tire wear than full-time four-wheel drive

- Increases traction and trimming ability to allow a novice operator to mow like an expert

- Works in the forward direction only

- Full-time four-wheel drive is on at all times.

- Can be engaged or disengaged on the go

- Provides maximum traction and flotation in poor conditions

- Works in reverse as well as the forward direction

- Two-wheel drive position is available on 1580 and 1585 with two-speed transaxle.

- Disengages rear axle when transporting at high ground speeds

Dual drive tires are available to optimize performance in challenging conditions (1550 and 1570 only)

Dual drive tires

Dual drive tires

Dual 23x8.5-12 drive tires are available for increased hillside stability, flotation, and reduced ground compaction.

In addition, single drive tires may be set in the narrow or wide position to match mowing conditions.

NOTE: These tires are available for the 1550 and 1570 models only.

Tail-follows-the-trail design helps avoid obstacles in turns

Tail follows the trail

1585 TerrainCut™ Front Mower

1585 TerrainCut™ Front Mower

Tail-follows-the-trail trimming with 72-in. (183-cm) mower decks. Steered wheels (tail) stay within the path (trail) cut by the mower deck, allowing maneuverability without the rear of the machine contacting mowing obstacles.

Maneuverability:

- Turn radius 13 in. (33 cm)

- Uncut circle – 28 in. (71cm) with a 72-in. (183-cm) 7-Iron PRO mower deck

- Deck offset for increased trim capability

Front mower ballast requirements

Front mowers must be properly ballasted for both good performance and safe operation. Ballast requirements differ depending on the front mower model and the implement being used.

The chart below gives the minimum ballast requirements for the various product configurations. Additional ballast is recommended for operating on slopes or other conditions that may warrant it.

NOTE: Use only implements and accessories recommended by the manufacturer.

Front mowers and current (model year 2015 and later) implements

TerrainCut™ 1500 Series Front Mowers |

|||||||||

Product Configuration |

60-in. (152- cm) Side- Discharge Deck (7- Iron™ PRO) |

72-in. (183- cm) Side- Discharge Deck (7- Iron PRO) |

62-in. (157- cm) Rear- Discharge Mower Deck |

72-in. (183- cm) Rear- Discharge Mower Deck |

60-in. (152- cm) HD Front Blade |

47-in. (119- cm) HD Two-Stage Snow Blower |

60-in. (152- cm) HD Two-Stage Snow Blower |

60-in. (152- cm) Rotary Broom |

43-in. (109- cm) Drop Spreader (Order Zone) |

1550 Front Mower 2WD |

1* |

2* |

1* |

2* |

0 |

2* |

3* |

1* |

NA*** |

1550 Front Mower 4WD |

0 |

1* |

0 |

1* |

0 |

2* |

2* |

0 |

Wide track |

1570 Front Mower 2WD |

1* |

2* |

1* |

2* |

0 |

2* |

3* |

1* |

NA*** |

1570 Front Mower 4WD |

0 |

1* |

0 |

1* |

0 |

2* |

2* |

0 |

Wide track |

1575 Front Mower |

Narrow track + 4 * |

Wide track + 5* |

Narrow track + 1 wheel weight on each side** + 3 weights* or wide track + 3 weights* |

Wide track + 6* |

1* |

NA*** |

6* |

Wide track + 1 wheel weight on each side** + 3 weights* |

With 60-in. Rotary Broom: wide track + 2 wheel weight on each side** or with 60-in. Snow Blower: wide track |

1580 Front Mower |

0 |

1* |

0 |

1* |

0 |

NA*** |

2* |

0 |

Wide track |

1585 Front Mower |

Narrow track + 4* |

Wide track + 5* |

Narrow track + 1 wheel weight on each side** + 3 weights* or wide track + 3 weights* |

Wide track + 6* |

1* |

NA*** |

6* |

Wide track + 1 wheel weight on each side** + 3 weights* |

With 60-in. Rotary Broom: wide track + 2 wheel weight on each side** or with 60-in. Snow Blower: wide track |

1400 and 1500 Series II Front Mowers |

|||||||||

1420 Series II Front Mower |

0 |

2* |

1* |

4* |

6* |

4* |

6* |

6* |

NA*** |

1435 Series II Front Mower |

0 |

2* |

1* |

4* |

6* |

4* |

6* |

6* |

NA*** |

1445 Series II Front Mower |

0 |

2* |

1* |

4* |

6* |

4* |

6* |

6* |

NA*** |

1545 Series II Front Mower |

0 |

2* |

1* |

4* |

6* |

NA*** |

6* |

6* |

NA*** |

1565 Series II Front Mower |

0 |

2* |

1* |

4* |

6* |

NA*** |

6* |

6* |

NA*** |

1575/1585 Cab models: Rim design allows for tire assembly to be mounted in two different configurations, a narrow track or wide track width to meet ballast requirements. |

|||||||||

*42-lb (19-kg) (UC13263) Quik-Tatch weight (installation requires TCB10303, rear weight mounting kit). |

|||||||||

**50-lb (23-kg) front wheel weight(s) required (installation requires BM18101, mounting hardware kit). |

|||||||||

***NA - Not recommended for use on front mower. |

|||||||||

NOTE: Ballast requirements may change. Always refer to the implement owner's manual for the appropriate ballast requirements. |

|||||||||

Front mowers and model year 2014 and prior implements

1400 and 1500 Series II Front Mowers |

|||||||||||

Product Configuration |

60-in. (152- cm) Side- Discharge Deck (7- Iron™ and 7-Iron II) |

72-in. (183- cm) Side- Discharge Deck (7- Iron and 7- Iron II) |

62-in. (157- cm) Rear- Discharge Mower Deck |

72-in. (183- cm) Rear- Discharge Mower Deck |

MCS 600 Hydraulic Dump |

Soft cab |

Hard cab |

60-in. (152-cm) HD Front Blade |

47-in. (119-cm) HD Two- Stage Snow Blower |

60-in. (152-cm) HD Two- Stage Snow Blower |

60-in. (152- cm) Rotary Broom |

1420 Series II Front Mower |

0 |

1* |

0 |

1* |

0 |

0 |

0 |

6* |

4* |

6* |

6* |

1435 Series II Front Mower |

0 |

1* |

0 |

1* |

0 |

0 |

0 |

6* |

4* |

6* |

6* |

1445 Series II Front Mower |

0 |

1* |

0 |

1* |

0 |

0 |

0 |

6* |

4* |

6* |

6* |

1545 Series II Front Mower |

NA |

1* |

NA |

1* |

0 |

0 |

0 |

6* |

NA |

6* |

6* |

1565 Series II Front Mower |

NA |

1* |

NA |

1* |

0 |

0 |

0 |

6* |

NA |

6* |

6* |

1500 TerrainCut Front Mowers |

|||||||||||

1550 Front Mower 2WD |

1* |

2* |

1* |

2* |

NA |

NA |

NA |

0 |

2* |

3* |

1* |

1550 Front Mower 4WD |

0 |

1* |

0 |

1* |

NA |

NA |

NA |

0 |

2* |

2* |

0 |

1570 Front Mower 2WD |

1* |

2* |

1* |

2* |

NA |

NA |

NA |

0 |

2* |

3* |

1* |

1570 Front Mower 4WD |

0 |

1* |

0 |

1* |

NA |

NA |

NA |

0 |

2* |

2* |

0 |

1575 Front Mower |

Narrow track + 4* |

Wide track + 5* |

Narrow track 1 wheel weight on each side** + 3 weights* or wide track + 3 weights* |

Wide track + 6* |

NA |

NA |

NA |

1* |

NA |

6* |

Wide track 1 wheel weight on each side** + 3 weights* |

1580 Front Mower |

0 |

1* |

0 |

1* |

NA NA |

NA |

0 |

NA |

2* |

0 |

|

1585 Front Mower |

Narrow track + 4* |

Wide track + 5* |

Narrow track 1 wheel weight on each side** + 3 weights* or wide track + 3 weights* |

Wide track + 6* |

NA |

NA |

NA |

1* |

NA |

6* |

Wide track 1 wheel weight on each side** + 3 weights* |

1575/1585 Cab models: Rim design allows for tire assembly to be mounted in two different configurations, a narrow track or wide track width, to meet ballast requirements. |

|||||||||||

* 42-lb (19-kg) (UC13263) Quik-Tatch weight (requires TCB10303, rear weight mounting kit). |

|||||||||||

** 50-lb (23-kg) front wheel weight(s) required (installation requires BM18101, mounting hardware kit). |

|||||||||||

NA - Not recommended for use on front mower. |

|||||||||||

NOTE: Ballast requirements may change. Always refer to the implement owner's manual for the appropriate ballast requirements. |

|||||||||||

Roll-Gard™ rollover protective structures protects operators of open-station mowers

ROPS (upright position)

ROPS (upright position)

ROPS (folded position)

ROPS (folded position)

The foldable two-post Roll-Gard rollover protective structure (ROPS) and retractable seat belt are standard equipment.

- Foldable for trimming, such as when mowing under trees or bushes

Specifications

Compare the specifications of up to 4 models

| Key Specs | 1550-terraincut-mower Current Model |

|---|---|

| Engine Manufacturer/model | 3TNV80F |

| Engine Power | Gross PS: 25 hp 18.4 kW |

| Fuel tank capacity | 16 U.S. gal. 60.6 L |

| Mower deck Size | 60 or 72 in. 152 or 183 cm |

| Blade tip speed | 18,000 fpm 5,486 m/min |

| Transmission | Hydrostatic 2WD, optional full time or on demand 4WD |

| Speed range | 0-12 mph 0-19.3 km/h |

| Drive wheels | 23x10.5-12 Optional: 23x8.5-12 |

| Caster wheels | Flat free, 11x4-5 |

| Warranty | 24 months |

| Engine | |

| Manufacturer/model | 3TNV80F |

| Power | Gross PS: 25 hp 18.4 kW |

| Rated engine rpm | 3,000 rpm |

| Cylinders | Three |

| Displacement | 77 cu in. 1.26 L |

| Maximum torque | At 1,900 rpm: 47.2 lb-ft 64 Nm |

| Injection | Indirect |

| Fuel type | Diesel (optional kit permits B20 compatibility) |

| Fuel tank capacity | 16 U.S. gal. 60.6 L |

| Cooling | Liquid |

| Cooling capacity | 7.5 U.S. qt 7.1 L |

| Air cleaner | Dual element dry type |

| Air restriction indicator | Standard |

| Charging system | Automotive type |

| Alternator, amp | 75 amp |

| Battery | 12 V |

| Drivetrain | |

| Transmission | Hydrostatic 2WD, optional full time or on demand 4WD |

| Speed and direction control | Two-pedal foot |

| Cruise control | Optional |

| Hi/Lo range | No, single speed transmission |

| Travel speed | |

| Speed range | |

| Hi forward | 0-12 mph 0-19.3 km/h |

| Lo forward | |

| Hi reverse | 0-5 mph 0-8 km/h |

| Lo reverse | |

| 4-wheel drive | |

| Differential lock | |

| Final drives | |

| PTO | |

| PTO clutch | |

| PTO drive output | |

| Hydraulics | |

| Type | Open center |

| Pump capacity | 5.1 U.S. gpm 19.3 L/min |

| Spool valve | Front lift, standard |

| Lift cylinders | Two |

| Steering | |

| Type | Hydraulic cylinder |

| Turns lock-to-lock | 2 maximum, 1.5 minimum |

| Brakes | |

| Type | Internal wet disk |

| Individual turn brakes | Standard |

| Master brake | Standard, locking |

| Buyer's notes | |

| Tires | |

| Drive wheels | 23x10.5-12 Optional: 23x8.5-12 |

| Steering | 2WD: 18x8.5-8 4WD: 18x8.5-10 |

| Weight transfer | |

| Dimensions | |

| Wheelbase | 49.2 in. 125 cm |

| Ground clearance | 6.5 in. 16.5 cm |

| Length | Less mower deck: 86.7 in. 220.2 cm |

| Overall width | Narrow Width 23x10.5 tires: 51.8 in. 131.6 cm Wide Width 23x10.5 tires: 60.3 in. 153.2 cm |

| ROPS | Standard (folding) |

| ROPS certification | Two-post: OSHA 1928; Canadian Std.: CSA-352 Four-post: SAE J2194; EU Standard: 86/298/EEC; ISO 21299:2009 |

| Overall height with ROPS | 82.7 in. 210 cm |

| Overall height with ROPS folded | 58 in. 147 cm |

| Shipping weight | Net weight, 2WD without mower or fuel: 1,675 lb 760 kg Net weight, 4WD without mower or fuel: 1,835 lb 832 kg |

| Mower decks | |

| Construction | One-piece stamped: 7-Iron PRO |

| Deck thickness | 7 gauge 0.18 in. 4.6 mm |

| Size | 60 or 72 in. 152 or 183 cm |

| Deck offset | Yes |

| Cutting height | 1-6 in. 2.54-15.24 cm |

| Belt tensioning | Spring loaded |

| Blade tip speed | 18,000 fpm 5,486 m/min |

| Caster wheels | Type Flat free Size 11x4-5 |

| Front anti-Scalp rollers | Yes, gauge wheels |

| Rear anti-scalp rollers | Yes, gauge wheels |

| Shipping weight | |

| Mower deck (rear discharge) | |

| Cutting width | 62, 72 in. 157, 183 cm |

| Cutting height | 1-6 in. 2.5-15.2 cm |

| Caster wheels | Type Flat free Size 11x4-5 |

| Shipping weight |

Accessories and Attachments

Auxiliary Hydraulics

Hydraulic weight transfer adjustment wheel

Hydraulic weight transfer adjustment wheel

The hydraulic weight transfer attachment allows transferring weight of an implement to drive wheels for improved traction in slippery or hilly areas. The hydraulic weight transfer adjustment wheel is located on the control panel to the right of the operator for easy use. It is adjustable from full-off to full-on while on the go.

One-spool auxiliary hydraulic kit for use on snow blowers for chute rotation or blade/broom angling:

- Allows operating implements that require one hydraulic function, such as for angling a snow blower chute or changing the angle of a front blade

Cold Start Packages

Heater

Engine coolant heater

Engine coolant heater Coolant heater adapter

Coolant heater adapterHeater adapter attaches to the engine cylinder block. Heater plugs into a 120-V electrical outlet to warm the engine for fast cold weather starts. It has a 400 W rated output.

Drive Wheels And Tires

Dual wheel shown

Dual wheel shownOrder this kit to convert the traction unit to have 23 x 8.5-12-in. dual drive wheels.

This kit includes spacers and hardware required to convert traction unit to dual drive wheels. Tires and rims are not included.

- NOTES:

- 1) 62-in. (158-cm) rear-discharge mower is not compatible with the dual wheel conversion kit.

- 2) Dual wheel conversion kit cannot be used in conjunction with the MCS 600 Hydraulic High-Dump Material Collection System.

Engine

John Deere engineering has tested the long-term effects of biodiesel fuel and fuel blends on product performance and durability extensively. Biodiesel conversion kits are now available for select John Deere professional mowing products.

Products:

- 1600 Series II Wide-Area Mower

What is biodiesel?

Biodiesel is an alternative fuel source produced from natural substances (such as regional corn crops), which is both biodegradable and environmentally sustainable. Typical blends of biodiesel fuel include B2, B5, B10, or B20. The B factor states the amount of biodiesel in any fuel mix; fuel containing 20 percent biodiesel is labeled B20.

Can biodiesel be used in standard diesel engines?

Diesel engines require a few modifications to run on biodiesel fuel blends:

- The biodiesel must meet the minimum specifications for the country in which they are used and should only be purchased from recognized and authorized diesel fuel suppliers.

- In Europe, biodiesel fuels must comply with the European Standard EN14214.

- In the United States, biodiesel fuels must comply with the American Standard ASTM D-6751.

- Without proper alterations, biodiesel can harm fuel system components – primarily hoses, pump seals, and filters.

- Biodiesel gels in cold conditions, similar to petroleum diesel fuel. Higher biodiesel blends typically gel faster, although biodiesel blends up to B20 require the same fuel management as petroleum diesel.

Known issues

While there are many advantages of biodiesel, be aware of some potential concerns:

- At temperatures below approximately 41°F (5°C) ambient temperature, a fuel heater may be required. Higher-viscosity fuel, from cold temperatures, may result in fuel-delivery problems such as injection pump seizure and/or poor injection nozzle spray atomization.

- John Deere recommends using only the fuel hoses listed in the parts catalog for the machine being repaired or serviced. Use of other hoses from different applications within John Deere or from outside hose suppliers may not be compatible with biodiesel fuels.

- Biodiesel fuels should be purchased only from recognized and authorized diesel fuel suppliers.

- Even biodiesel fuels that comply with a suitable standard as delivered require additional care and attention to maintain the quality of the fuel in the equipment or other fuel tanks. It is important to maintain a supply of clean, fresh fuel.

- National Biodiesel Board's direct phone number is: 1-800-841-5849. The National Biodiesel Board (NBB) is the national trade association representing the biodiesel industry as the coordinating body for research and development in the United States. The NBB Web site is www.biodiesel.org.

- John Deere continues to monitor available information on biodiesel products. Future testing of different fuels may be done as their popularity increases.

- Painted surfaces may be damaged by biodiesel fuel/blend contact.

- Any on-site fuel tank must be equipped with a ten micron (or finer) filter.

- To maintain fuel quality, no more than three months fuel supply should be kept on-site.

- Biodiesel concentrations of 5 percent or lower are recommended for winter (or cold-weather) operation. As with 2D petroleum-based fuel, blending with 1D fuel and/or cold-weather additives (pour point depressants) is required.

- All seals, hoses, gaskets, and wire coats must be monitored as they may swell, crack, or become tacky over time.

- Following the conversion of a unit that has previously run on petroleum/diesel-based fuel, one or two instances of premature fuel filter plugging can be expected; this is caused by the dissolution and washing of fuel deposits into the filter and is considered normal.

- Aging and oxidation lead to increased acids and the formation of gum that may plug the filters.

- Biodiesel should not be left in the system. If product is going to be stored more than three months, drain the fuel tank and lines to the engine, put in a sufficient quantity of petroleum diesel fuel, and purge the engine of all biodiesel.

For additional information, please reference Dealer Technical Assistance Center (DTAC) solution 86900.

Hydraulics

Lighting

This light is required by some governmental agencies and on some worksites. It provides increased visibility of the unit when in operation and mounts to the top of the rollover protective structure (ROPS).

- NOTE: The beacon light mounts to the top right ROPS tube on two-post ROPS and four-post ROPS assemblies.

Front mower with four-post ROPS and front worklights

Front mower with four-post ROPS and front worklights Front worklights

Front worklightsFront worklights mount to the top frame of the four-post ROPS.

Mirrors

Gives the operator a view to the rear at a quick glance.

Miscellaneous

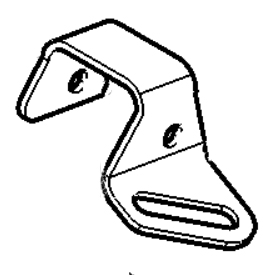

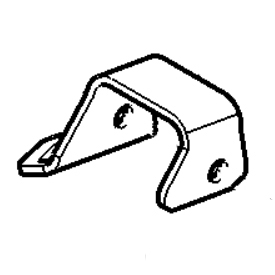

Left-hand front tie-down bracket illustration

Left-hand front tie-down bracket illustration Right-hand front tie-down bracket illustration

Right-hand front tie-down bracket illustrationFront tie-down brackets provides great locations to secure a front mower when hauling. The tie-downs are left- and right-hand, mounted to the lift-arm receivers. They are designed specifically for the John Deere 1500 Series TerrainCut™ Front Mowers. Tie-downs are useful for any hauling application to make securing the vehicle easier and better:

- TCU38441 left-hand front tie-down bracket

- TCU38442 right-hand front tie-down bracket

Key features include:

- Constructed with 0.25-in. (6.4-mm) A36 steel plate

- Designed specifically for the John Deere 1500 Series TerrainCut Front Mowers

- Simple bolt-on design

- Does not interfere with mower deck

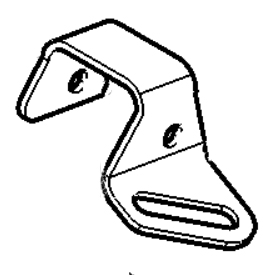

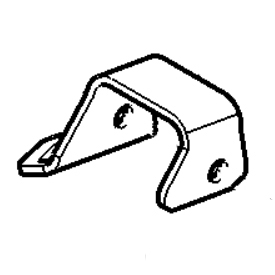

Left-hand front tie-down bracket illustration

Left-hand front tie-down bracket illustration Right-hand front tie-down bracket illustration

Right-hand front tie-down bracket illustrationFront tie-down brackets provides great locations to secure a front mower when hauling. The tie-downs are left- and right-hand, mounted to the lift-arm receivers. They are designed specifically for the John Deere 1500 Series TerrainCut™ Front Mowers. Tie-downs are useful for any hauling application to make securing the vehicle easier and better:

- TCU38441 left-hand front tie-down bracket

- TCU38442 right-hand front tie-down bracket

Key features include:

- Constructed with 0.25-in. (6.4-mm) A36 steel plate

- Designed specifically for the John Deere 1500 Series TerrainCut Front Mowers

- Simple bolt-on design

- Does not interfere with mower deck

Double-Spool Auxiliary Hydraulic Kit - BTC10529

The cruise control kit maintains desired speed without foot pressure.

The reverse alarm attachment is available for improved safety and for those who require an alarm in reverse speeds to satisfy safety regulations and governmental bid requirements.

This emblem attaches to the ROPS for transporting on public roads. Available on cab and open-station models.

Drive tires are available for field installation.

Drive tires are available for field installation.

Vehicle enclosure kit illustration

Vehicle enclosure kit illustration Vehicle enclosure kit installed illustration

Vehicle enclosure kit installed illustrationThis vehicle enclosure kit limits the amount of debris buildup around the transmission and engine, making daily maintenance and service fast and easy.

The vehicle enclosure kit is shipped with a 62-in. (157-cm) or 72-in. (183-cm) rear-discharge deck from the factory as standard equipment and is dealer installed. It may be ordered as an attachment for 62-in. (157-cm) or 72-in. (183-cm) 7-Iron™ PRO Commercial Side-Discharge Decks.

Roll Over Protection System (Rops)

Four-post ROPS

Four-post ROPS Four-post ROPS

Four-post ROPSThe four-post ROPS consists of two front posts, welded top and bottom assemblies, and a molded roof.

Tire Chains

Tire chains provide additional traction for the machine.

Tire chains provide additional traction for the machine.

Weights

Wheel weight

Wheel weightOne or two weights can be installed on each drive wheel if extra traction is desired.

Wheel weights will fit on both the 1400 and 1500 Series II Front Mowers.

Mounting hardware (one) for attaching 72-lb (34-kg) starter weight and (two) 50-lb (22.7-kg) cast-iron weights on 26-in. (66-cm) tire

Weight

WeightThe 42-lb (19-kg) Quik-Tatch weight can be used to counterbalance a heavy front or rear attachment and/or provide greater stability, especially when operating on hills.

Weights are constructed of cast iron and weigh approximately 42 lb (19 kg) each.

Rear weight mounting bracket parts

Rear weight mounting bracket parts Rear weight mounting bracket with weights

Rear weight mounting bracket with weightsAllows operator to mount ballast weights for additional traction (four R66949 or UC13263 42-lb (19-kg) Quik-Tach weights are recommended for snow blower applications).

Windshield

This front windshield mounts to the four-post ROPS.

- Compatible with:

- 1500 Series TerrainCut™ Front Mowers

- 1400/1500 Series II Front Mowers

Reviews

4 reviews

- Filter

- Star Rating

- Value

- Quality