Features

5M Tractor premium cab with 4240 Universal Display

5M Tractor premium cab with 4240 Universal Display

Overview

The premium cab is designed to provide the ultimate operator experience in comfort and convenience. With the adoption of some 5R Tractor cab structures and features, John Deere has added more technology options, better visibility, and an updated, user-friendly digital display.

Benefits

- Upward visibility has improved 80 percent with the panorama roof in the premium cab, allowing for easier bale stacking, pallet stacking, and dumping loads into walled trailers.

- The rear floor mat behind the seat provides additional storage space.

- The rearview mirror is positioned for excellent visibility to rear operations.

- To shield the operator from the sun, there is an easy to use front sunshade.

5M Tractor cab with panorama roof

5M Tractor cab with panorama roof

Some of the key features include:

- Deluxe sound package with two 4X6 coaxial speakers and subwoofer

- Factory-installed radio

- Bluetooth® wireless ready

- Satellite ready

- USB port

- Auxiliary cord connection

- Additional heating and cooling vents

- Rear windshield wiper and washer

Bluetooth is a trademark of Bluetooth SIG, Inc.

The PowrReverser transmission provides 16 forward speeds and 16 reverse (16F/16R) speeds and is equipped with the factory-installed high/low creeper. This transmission comes standard with a dual speed 540/540 Economy power take-off (PTO) and is ideal for applications requiring frequent directional changes.

Hydraulic wet forward and reverse clutches maximize durability and outlast the life of any dry clutch. When tractors are run by multiple operators with a variety of experience levels, a wet clutch is the best way to maintain transmission integrity and performance while decreasing clutch replacement costs.

Two platform-mounted levers offer easy and comfortable shifting for a pleasant operator experience. The gear-shift lever is easy to reach and the less-used range lever is shorter. Unique knobs make it easy to distinguish between the two.

The forward lever selects one of four speeds, all synchronized shifts for on-the-go shifting with the use of the clutch. The rear lever selects ranges A, B, C, or D. Ranges C and D are fully synchronized. When upshifting, operators can move from range C to D without stopping the tractor. On the downshift, operators can move from D all the way to B without stopping. There is a separate lever for creeper operation.

16F/16R transmission includes:

Wet clutch

Platform-mounted shift levers (four gears, four ranges)

Left-hand reverser

Constant-mesh helical-cut gears

Pressure-lubricated top shaft

Positive park pawl

Neutral start switch

Gear shift lever

Gear shift lever

Range shift lever

Range shift lever

Maximum productivity is achieved with clutchless hydraulic shifting between forward and reverse and is ideal for any applications that require frequent directional switches in tight spaces. An electrohydraulic fingertip directional lever control allows the operator to effortlessly switch directions with a small finger motion. The control is located on the left side of the instrument console and selects forward, reverse, and neutral positions. It also allows the operator to steer and shift direction with the left hand, freeing the right hand to operate other tractor controls, such as the loader, rear implements, or hand throttle. The PowrReverser™ has a built-in engagement override valve for additional safety. This valve requires the clutch pedal to be depressed one time after each engine start before the transmission will begin to operate normally, giving the operator another opportunity to put all focus on the tractor.

Left-hand reverser lever

Left-hand reverser lever

NOTE: A neutral start switch requires the directional lever be in the neutral position to start the engine.

The creeper gears are accessible by engaging the creeper lever into rabbit or turtle position.

Creeper lever

Creeper lever

All tractors have economy power take-of (E-PTO) (a fuel saving feature) that allows customers to operate rear implements at 540 PTO rpm but at lower engine rpm. The result is lower engine vibration, reduced noise, less wear and tear on the engine, reduced fuel consumption and increased operator comfort.

**See PTO Functional area for more information on EPTO**

Controlling the 5M is easier and brighter than ever before. A fresh new instrument cluster displays information in a crisp, vibrant, and useful array. A larger alternator (OOS: 90 amp, cab: 120 amp) produces plenty of power for internal and external components.

This window into tractor functionality and diagnostics provides ample information. Indicators, warning lights, and even the gauges are clear and bright. The roll-mode function now provides operators with crucial onboard diagnostics. Engine hours, PTO speed, ground speed, hi-lo indicator, forward, neutral, and reverse, are all visible at the same time. There is a light-out indicator for trailer light, turn light, and hazard light bulbs which is driven by new software. A straightforward layout and sleek design requires no customer interface. When operating the PTO, there are clearly presented PTO target bars to indicate the correct PTO speed.

Instrument cluster - cab

Instrument cluster - cab

PTO target bars

PTO target bars

There are daytime and nighttime modes which are based on the position of the light switch. The mode actually adjusts the backlight levels of the display for optimum visibility.

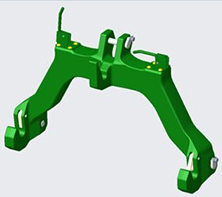

5M Tractor 3-point hitch

5M Tractor 3-point hitch

Overview

Heavy-duty 3-point hitch provides lift capacity and adjustability for implement versatility with Category 2 implements or adaptable to Category 1. Precisely raise and lower heavy implements such as planters, sprayers, and field cultivators, using the rockshaft control lever. The operator can also adjust the speed at which an implement is lowered by adjusting the rockshaft rate of drop.

Benefits

- Convenience hooking up implements with telescoping draft links, adjustable sway bars, and interchangeable hitch balls with the choice of either mechanical or electrohydraulic controls.

- Consistency when lowering hitch with depth stop on both mechanical and electrohydraulic hitch controls - each time the position control lever is pushed forward, it stops where the depth stop has been positioned. Useful when preparing a seedbed.

- Compatible with implements needed to perform multiple jobs. Increased lift capacity is available with optional larger cylinders. See Specifications for lift capacity by model.

- Convenience when leveling implements with right lift link being able to adjust without tools - lift links can be adjusted for lateral float to allow implements with gauge wheels or skids to follow the ground contour

Additional details

Mechanical or electrohydraulic hitch control operation

Raise and lower rear implements with precision with either the mechanical or electrohydraulic (EH) hitch control. The operator can also adjust the speed at which an implement is lowered by adjusting the rockshaft rate of drop.

The mechanical hitch control is paired with the tractors equipped with a PowrReverser™ transmission while the EH hitch control is paired with units equipped with a PowrQuad™ PLUS or Powr8™ transmission. Both control types enable the operator to adjust the speed at which an implement can be lowered by adjusting the rockshaft rate of drop. In addition to this feature, the EH hitch control adds repeatable movements by enabling the operator to set both an upper and lower limit.

The adjustable depth stop (found on both control types) provides consistency when lowering the hitch. Each time the position control lever is pushed forward, it stops where the depth stop has been positioned. This feature is a value to anyone who desires a consistent, level ground, like when preparing a seedbed.

The center link can be set in one of three positions to accurately set the implement position and draft sensing. The right lift link is adjustable without tools for added convenience when leveling implements.

Optional larger cylinders:

Transmission |

Cylinder diameter |

Lift capacity at 610-mm (24-in) behind lift point |

PowrReverser™ transmission models |

Two 65-mm (2.56-in.) cylinders |

See specifications for lift capacity. |

PowrReverser models with optional high-capacity hitch |

One 65-mm (2.56-in.) cylinder |

|

PowrQuad PLUS or Powr8 transmission models |

Two 75-mm (2.95-in.) cylinders |

|

PowrQuad PLUS or Powr8 models with optional high-capacity hitch |

Two 80-mm (3.15-in.) cylinders |

Rear fender hitch controls

5M rear fender hitch controls

5M rear fender hitch controls

Operators do not need to carry a tool to adjust the rear hitch. Operators can also raise and lower the 3-point hitch from outside of the tractor with the conveniently located rear fender hitch controls.

Rear quick hitch

Rear quick hitch

Rear quick hitch

Sideview of quick hitch shown on 5M

Sideview of quick hitch shown on 5M

An updated three-point quick hitch is offered on the 5M Tractors.

- This updated design is a break from the existing welded quick hitch as the frame is cast.

- The curved design eliminates the potential for contact with the rear fender and extensions.

- The quick hitch is available as a field kit option.

Sway bars

5M Tractor sway bars

5M Tractor sway bars

Adjustable sway bars and telescoping draft links can be easily adjusted to adapt to a wide variety of implements. The right lift link also adjusts without tools for added convenience when leveling implements.

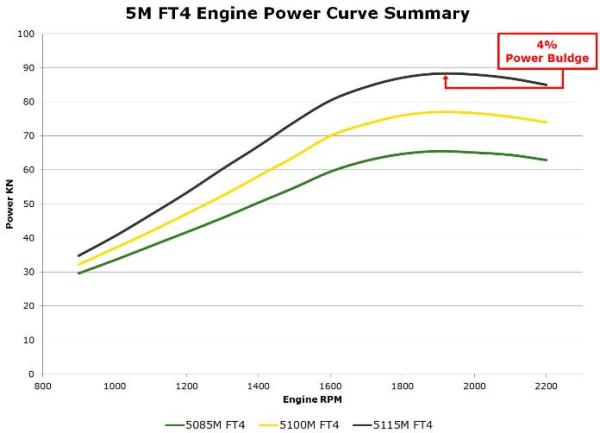

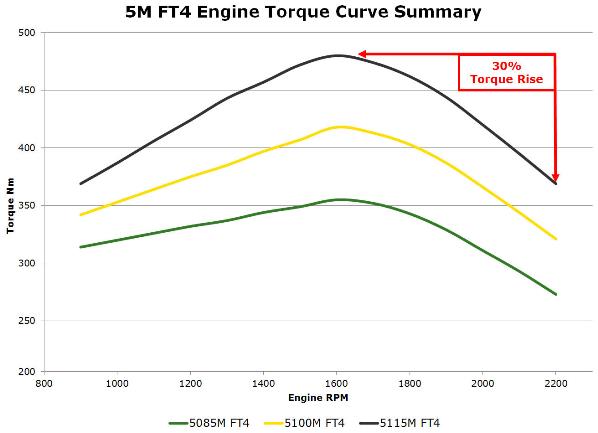

5M Final Tier 4 (FT4) engines feature up to a 4 percent power bulge when put under load. The power bulge feature of the electronically controlled engine delivers additional horsepower as engine rpm drops below rated speed. Additionally, a 30 percent torque rise provides the force that maintains horsepower as engine rpm drops below rated speed.

When the tractor is under load, power bulge and torque rise work together to get through the tough spots without having to downshift. Horsepower and torque are mathematically related.

|

As rpm drops, the only way to maintain or increase horsepower is to provide additional torque. The output horsepower is greater than or equal to rated horsepower as the engine is pulled down to 1750 rpm.

The peak torque rise also occurs near the rated economy power take-off (EPTO) speed.

5M power curve summary

5M power curve summary

5M torque curve summary

5M torque curve summary

Specifications

| Key Specs | 5100mh Current Model |

|---|---|

| Engine description | John Deere PowerTech™ PWS |

| Engine displacement | 4 cylinders: 4.5 L 276 cu in. |

| Rated engine power | At 2200 per ISO 97/68/EC: 74.0 kW 99.2 hp |

| Maximum engine power | 77 kW 103.3 hp |

| Rated PTO power (hp SAE) | At 2100 per SAE: 63.4 kW 85 hp |

| Transmission type | Standard: PowrReverser™ 16F/16R with creeper |

| Hydraulic pump rated output | 94 L/min 24.7 gpm |

| Rear hitch category (SAE designation) | Category 2; convertible to 1 |

| Engine specifications | |

| Description | John Deere PowerTech PWS |

| Engine family | MJDXL06.8309 |

| Aspiration | Turbocharged/Air-to-Air Aftercooled |

| Cylinders liners | Wet sleeved |

| Emission level | Final Tier 4 |

| Displacement | 4 cylinders: 4.5 L 276 cu in. |

| Engine performance | |

| Rated power | At 2200 per ISO 97/68/EC: 74 kW 99.2 hp |

| Rated PTO power (hp SAE) | At 2100 per SAE: 63.4 kW 85 hp |

| Power boost | At 1900 rpm: 4 percent |

| Maximum engine power | 77 kW 103.3 hp |

| Engine peak torque | At 1600 rpm: 418 Nm 308 lb-ft |

| PTO torque rise | At 1600 rpm: 30 percent |

| Transmission | |

| Type | Standard: PowrReverser™ 16F/16R with creeper |

| Reverser | Left hand, electrohydraulic |

| Clutch; wet/dry | Wet |

| Creeper | PowrReverser™ 16F/16R with creeper |

| Hydraulic system | |

| Type | Open Center |

| Pump rated output | 94 L/min 24.7 gpm |

| Available flow at a single rear SCV | 70 L/min 18.4 gpm |

| Number of rear selective control valves (SCVs) | Two, up to three total |

| Number of mid selective control valves (SCVs) | Two, up to three total |

| Joystick SCV control | Optional |

| SCV control | Mechanical |

| Rear hitch | |

| Hitch draft control load sense type | Mechanical or electrohydraulic |

| Remote control valves available | Standard: 2 Optional: 3 |

| Hitch category (SAE designation) | Category 2; convertible to 1 |

| Maximum lift capacity behind lift points | Standard: 2336 kg 5150 lb Optional: 2699 kg 5950 lb |

| Sensing type | Lower Link |

| Rear axle differential lock | Electrohydraulic |

| Drawbar | |

| Maximum vertical load | Road/field use (250-mm extended): 1450 kg 3197 lb Field use (350-mm extended): 1200 kg 2646 lb Field use (400-mm extended): 1200 kg 2646 lb |

| Rear power take-off (PTO) | |

| Type | Independent, 34.9 mm (1.375 in) Standard: 540/540 Economy (6 spline) Optional: 540/540E (6 spline) and 1000 rpm (21 spline) reversible shaft |

| Engine rpm (at rated PTO speeds) | 540 at 2100 rpm 540E at 1645 rpm 1000 at 2100 rpm |

| PTO actuation | Electrohydraulic |

| Front hitch | |

| Rear axle | |

| Final drive type | Inboard planetary |

| Differential controls | Electrohydraulic |

| Axle type | Flanged Drop Axle |

| Brakes, type and control | Hydraulic wet disc |

| Front axle | |

| Tires | |

| Rear | MFWD: 230/95R48 R1W |

| Wheel tread range | MFWD: 1340-1904 mm 52.8-75.0 in. |

| Turning radius with brakes | MFWD: 3.9 m 12.8 ft |

| Turning radius without brakes | MFWD: 4.7 m 15.4 ft |

| Tracks | |

| Steering | |

| Brakes | |

| Electrical system | |

| Alternator size | Standard: 90 amp Optional: 120 amp |

| Battery options | 12 V |

| Working lights | Standard: Halogen Optional: LED |

| Type of bulb in headlight (Halogen, Zenon, LED) | Standard: Halogen Optional: LED |

| Type of bulb in beacon (Halogen, Zenon, LED) | Optional: LED |

| Operator station | |

| Rollover protective structure, OOS | Rigid - foldable - telescopic Foldable, 2-post Platform - flat/straddle Flat Gearshift location - console/floor Floor |

| Seat | Standard: Mechanical suspension Optional: air ride or premium air ride |

| Instructional seat | Optional |

| Display | Automotive-style light-emitting diode (LED) instrument cluster |

| Radio | Optional |

| dB(A) rating | 78 dBA |

| Dimensions | |

| Wheelbase | MFWD: 2350 mm 92.5 in. |

| Approximate shipping weight, Open;Cab | MFWD: Open: 4520 kg 9947 lb Cab:4710 kg 10364 lb |

| Weight | |

| Capacities | |

| Fuel tank | Standard: Open: 140.8 L 37.2 U.S. gal. Cab: 140.8 L |

| Diesel exhaust fluid (DEF) tank | 12 L 3.17 U.S. gal. |

| Serviceability | |

| Loaders | |

| Precision AG | |

| Telematic | Standard: Less JDLink™ Hardware Optional: JDLink™ Modem |

| Miscellaneous | |

| Country of manufacture | Pune, India |