324 P WHEEL LOADER

Compact Wheel Loader

- Net Power: 52 kW (71 hp) at 2,400 rpm

- Operating Weight: 6400 kg (14,110 lb.)

- Bucket Capacity: 0.8–1.6 m3 (1.0–2.1 cu. yd.)

Apply For FinancingMaintenance Plans

60 Day Promise

Features

Articulation Plus™ Steering provides a tighter turning radius and increased stability

244 P-Tier articulating

244 P-Tier articulating

P-tier compact wheel loaders continue to feature industry exclusive Articulation Plus™ that adds rear wheel steering to increase full turn tipping load and improve maneuverability

- This steering system combines 30 degrees of standard articulation with an additional 10 degrees of rear-wheel steering.

- Articulation Plus™ enables a significantly higher full turn tipping load than machines without this feature because the machine does not need to articulate as much to turn

- This feature results in a significantly tighter turning radius than comparatively sized loaders without Articulation Plus™

Increase your machine’s versatility with John Deere’s wide array of attachment offerings

Loader with Snow Blower

Loader with Snow Blower

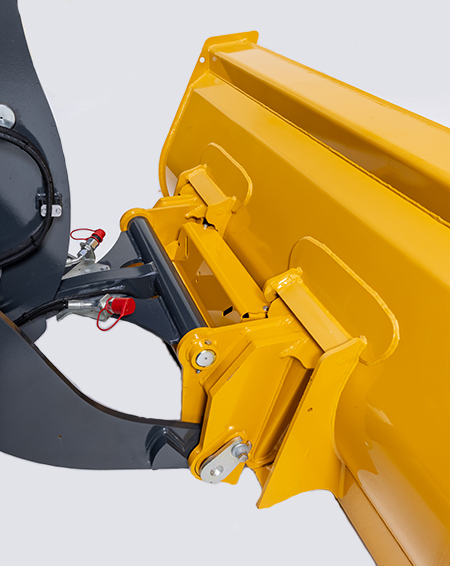

Skid Steer Style Quik-Tatch Coupler

Skid Steer Style Quik-Tatch Coupler

Joystick with 3rd function mini-joystick control

Joystick with 3rd function mini-joystick control

With over 100 attachments offered in the John Deere attachment portfolio you can make the most out of your compact wheel loader by equipping it with many popular attachments.

- Skid Steer Quik-Tatch coupler and Hook/Euro Style Couplers allow increased optionality to utilize a range of attachments and the common interface means previous series attachments will be able to be used on these new series of machines as well.

- Optional attachment assist controls make it easier for operators to get the most out of attachments by combining throttle lock and creep control to maintain full power at a set ground speed.

- Standard joystick includes integrated Forward-Neutral-Reverse (FNR) switch and 3rd function mini-joystick detent control for ease of attachment operation.

- Standard auxiliary hydraulics and optional High Flow hydraulics allows the use of attachments like snow blowers or augers. By simply pressing a switch in the cab, operators can easily connect and disconnect attachments and enable them to have full function flow without having to manually press buttons throughout the day

- Optimized forks for compact wheel loaders offer improved visibility, increased capacity, and better durability. Designed specifically for compact loaders, they enable operators to load the far side of a trailer with ease

Enjoy all day comfort with the spacious and ergonomically friendly cab

Hi-Back seat and adjustable steering column within cab

Hi-Back seat and adjustable steering column within cab

Storage area

Storage area

Right side console

Right side console

Display

Display

The operator focused designs found within John Deere Compact Wheel loaders ensure operators are comfortable and productive all day.

- P-tier loaders bring over the significant cab upgrades seen in L-series wheel loaders that featured an overall larger cab that is both wider and longer compared to previous series

- To help keep operators more comfortable during a long shift, the air conditioning system contains an array of adjustable louvers. The optimized duct work coupled with these louvers provide increased airflow and allow the operator to direct airflow where it is needed.

- Ergonomic, low effort controls all on the right side, allow operators to work comfortably and more efficiently

- Machine display is mounted to the cab A-frame and is height adjustable

- Ample storage within the cab allows operators to keep personal items close and secure

- Adjustable steering column allows operators to easily move the steering wheel to a desired position to help increase productivity and allow easy ingress and egress.

- Optional premium high-back, air suspension heated seat provides top of the line comfort for operators in off road conditions and colder climates

- The left pedal acts as a brake and inching pedal. If the operator pushes all the way down, the machine comes to a complete stop. If the operator presses the pedal without going all the way down, the machine will proportionally move slower and continue at that speed

Productivity enhancements that can benefit you regardless of the machine’s application

Loader moving hay bales

Loader moving hay bales

Compact Wheel Loaders come with features that result in higher productivity in applications like V-pattern truck loading, bale handling, and landscaping

- The Yanmar 4TNV98CT engine features a high pressure common rail fuel system and a turbocharger. Both the 244 and 324 P-tier loaders meet Final Tier 4 emissions regulations through the use of cooled exhaust gas recirculation (EGR), a diesel oxidation catalyst (DOC), and a diesel particulate filter (DPF). Because the 244 P-tier and 324 P-tier are under 75 gross horse power, diesel exhaust fluid is not needed.

- The 244 P-tier and 324 P-tier have a maximum travel speed of 38 km/h (23 mph) enabling them to move around jobsites much quicker

- Automatic shift logic has been internally developed to allow the operator to focus on their work instead of shifting gears. This allows the machine to seamlessly transition from loading to transport. The system senses the machine speed and load and will adjust the hydrostatic pumps, motors, and gearbox automatically without operator input to best match the conditions.

- Manual low-speed 100-percent differential lock delivers the ground gripping tractive effort necessary to dive deep into the pile and help heap the bucket.

- Standard ride control reduces material spillage from the bucket when traveling over rough and uneven terrain by cushioning the boom. This will help in getting the material being moved to where it is intended to go, and will reduce site cleanup that may result from spilled material.

- The 244 P-tier and 324 P-tier include rim pull control that allows adjustment of tractive effort for better operation in loose underfoot conditions. It allows customers to adjust the machine to the operating conditions to help prevent the tires from spinning and therefore improve tire life and powertrain life.

- High lift linkage option on the 324 P-tier adds additional height to hinge pin to increase things like dump height and reach

Ease of serviceability allows you to spend more time completing the tasks at hand

Hood tilted up at rear of the machine

Hood tilted up at rear of the machine

Right side cooling package access and fuel and DEF fill

Right side cooling package access and fuel and DEF fill

Enhanced serviceability features and ease of access to daily and preventative maintenance points ensures that these tasks do not significantly cut into working hours

- Ground level service simplifies daily maintenance, keeping machine in good working condition without cutting into working hours. This also enables operators to change fluids quickly and cleanly to keep equipment running smoothly

- Cooling package optimizes efficiency and cleanout. The unique diagonal flow through design is efficient because it minimizes contamination from debris build up. This significantly reduces material buildup on the coolers. The coolers are also spaced to allow ease of access for cleanout from ground level.

- To maximize time spent on the job instead of in the shop, compact wheel loaders feature extended service intervals for engine oil and filter, final drive oil, and hydraulic oil.

- Compact wheel loaders are supported by one of the largest dealer networks in the industry meaning more technicians in the shop and field and more parts on the shelf to keep machines up and running.

- The automatic spring-applied hydraulically released park brakes help maximize uptime and are a safer and more reliable feature than most competitor’s cable operated park brakes.

Excellent visibility for increased situational and jobsite awareness

Rear sloped hood and window

Rear sloped hood and window

View from operator’s seat

View from operator’s seat

Lighting locations

Lighting locations

Compact Wheel Loaders are built with operator visibility in mind. From the tapered boom to the rear sloping hood and everything in between, operators will have great visibility from the cab to all sides of the machine.

- Single boom and bucket cylinder in line with each other helps ensure the operator is able to efficiently change out between attachments

- Tapered boom design offers improved parallel lifting capabilities especially when forks are being used in applications like landscaping. The design also provides excellent viewing of attachments and material.

- Sloped rear hood and rear-view mirrors allow superior views to the rear of the machine when backing up

- Compact wheel loaders offer great visibility for the operator by positioning them higher up in the cab compared with other compact construction equipment.

- Optional light-emitting diode (LED) lighting package that offers two different styles of LED lights, results in increased productivity in low light conditions due to significantly better illumination of the machine surroundings. It will also result in a more durable and reliable light source over time when compared to standard halogen bulbs.

Specifications

Compare the specifications of up to 4 models

| DRIVELINE | 324-p-wheel-loader Current Model |

|---|---|

| Engine Manufacturer | Yanmar |

| Engine Model | 4TNV98CT |

| Displacement, ltr (Inches³) | 3.3 (203) |

| Rated Speed, rpm | 2400 |

| Engine Output - Net, kW (hp) | 52 (71) |

| Torque, Nm (lbf / ft) | 280 (206) |

| Transmission Type | Hydrostatic |

| Front Differential Type | Locking |

| Rear Differential Type | Open |

| Tire size - Standard | 405 / 70 R20 |

| Service Brake - Type | Wet Disc & Drum |

| Service Brake - Actuation | Hydraulic |

| Parking Brake - Type | Wet Disc |

| DIMENSIONS | |

| Height - Over Cab, mm (ft/in) | 2780 (9 ft 1 in) |

| Wheelbase, mm (ft/in) | 2300 (7 ft 7 in) |

| Ground clearance, mm (inches) | 295 (12) |

| Width Over tires - Std, mm (ft/in) | 2090 (6 ft 10 in) |

| Height - Pivot Pin, mm (ft/in) | 3350 (11 ft ) |

| Reach - At 2130mm 45° Dump, mm (ft/in) | 1660 (5 ft 5 in) |

| CAPACITIES | |

| Fuel Tank, ltr (gallons (US)) | 90 (23.8) |

| Hydraulic Tank, ltr (gallons (US)) | 66 (17.4) |

| Heaped Capacity, m³ (yd³) | 1.1 (1.4) |

| Breakout - Bucket, kgf (lbf) | 5650 (12456) |

| Ride Control System | Yes |

| Pump Type | Gear |

| Pump Flow - 1, lt/min (gallons (US) / min) | 93 (25) |

| System Pressure, bar (PSI) | 189.6 (2750) |

| WEIGHTS | |