660R LOADER

Loader

- Tool-free removal and attachment with just a few, simple steps

- Frame design that allows for maximum maneuverability

- Automatic Mast Latch system for quick change from loader to three-point implements

- Repositioned leveling links for better visibility

Maintenance Plans

Features

Time and cost savings with Loader Technology package preparation

The loader technology package prep provides the installed harness to further install a hardware bundle that has four features to make material handling easier and more efficient. The package is only for mid-model year 2022 6R 110 to 6R 250 Tractors when equipped with the electric joystick and mid- valves.

Technology package hardware unlocks the following loader features when DWS option code is ordered with Loader Technology package prep:

- Dynamic Weighing System (DWS)

- Level to Horizon (LTH)

- Return to Position (RTP)

- Electronic self-leveling (ESL)

- Optional loader camera

Return to Position (RTP)

This feature moves the loader boom and bucket automatically to predefined positions. The operator can save two sets of boom height and bucket angles (A and B). With one short push or pull of the joystick, the loader automatically returns the boom and bucket to the desired position.

Mid-model year 2022 6R Tractor E-ICV joystick

Mid-model year 2022 6R Tractor E-ICV joystick

Filling a manure spreader then only requires a few joystick movements and no manual controlling of heights and angles to avoid collisions:

- One joystick movement each for the boom and the bucket – loader simultaneously levels the grapple bucket and lowers the boom just above the ground.

- One joystick movement – loader raises the boom above the manure spreader.

- One joystick movement – loader empties the manure fork.

When more positions are needed, such as loading bales in two layers on a trailer or including transport heights and angles in the positioning feature, the second set of positions (b) can be used. All values and settings are shown in the main screen of the tractor, including the current bucket angle.

RTP can easily be switched off if manual operation is preferred.

Level to Horizon (LTH)

This feature levels the attachment parallel to the ground, while conventional loader leveling systems maintain the same angle versus the tractor. This means that when riding in hilly conditions or over curbs on the farm, the pallet fork, bucket, or other attachment is actively moved into a horizontal position. If this behavior is not desired by the operator, it can be turned off in the tractor display. The attachment is then leveled to the tractor if equipped with a leveling feature such as mechanical self-leveling (MSL).

Dynamic Weighing System (DWS), if equipped (code 9661)

The DWS feature displays the current weight loaded in the attachment, such as a bucket. The tractor does not need to stop for weighing, allowing the operator to fill up a bucket to the required target weight without interrupting for a separate weighing cycle. It also allows the operator to enter target weights per component, such as silage, forage, or soy. This provides an instant overview of needed ingredients for feeding wagons and other loading tasks. If starting a new silage pit with changed nutrition value, the target value for this single component is easily adjustable.

A bar diagram and displayed values clearly show how much weight of the current component is still needed to achieve its target weight.

The operator can easily switch between the different components. This enables an improved way of filling feeder wagons, unlocking unexpected fuel saving potential. Currently, operators fill one component after the other into the feeding wagon to compare the sum of this component with a memorized or written value. Then, the next component is added to again compare its component sum with the scale on the feeder wagon.

With DWS, operators can fill forage, silage, and more in mixed sequence, as it saves the subtotal of each component individually and not just the total sum. This allows the operator to change the material with each bucket, providing already mixed content in the wagon without running it.

The weighing system includes a counter for every loading cycle. The tractor counts with every loading cycle, confirmed by simply pushing a button integrated into the loader joystick. The weighing system even registers multiple units. For example, when handling two bales in one grapple, the tractor can count two bales with every loading cycle.

Liquid goods in containers can also be weighed. The container with the liquids can be weighed before and after the unloading cycle; the difference is added to the respective weighing cycle. This should be done with a leveled pallet fork or large bag, which is possible with DWS as it does not require a certain bucket angle for the weighing process.

Electronic self-leveling (ESL)

ESL maintains bucket positioning in any range of the boom. It can be easily activated and deactivated from the run pages.

Benefits

- Faster and easier loading of goods with RTP

- No manual controlling of heights and angles to avoid trailers, sheds, etc.

- Weighing on the go without the time-consuming need to stop and perform a weighing cycle for every bucket

- No time lost for returning excessive load from mixer wagons

- No effort to rewrite the target weight of all individual components when changing silage pits with a different nutrition value or varying herd size

- No need to purchase a feeder wagon scale

- Fast filling of target weight in the bucket without interrupting to verify the current weight

- Automatic bale counter versus paper notes in the cab

- Can weigh liquids and even partial loads on pallets or in containers and buckets

- Avoid spilling goods or transport multiple bales without dropping them with the LTH feature

Loader camera option when ordered with Loader Technology package (code 9662)

Tractor showing the loader camera image

Tractor showing the loader camera image

The loader camera provides visibility to the loader carrier and surroundings. The hooks of the carrier are visible to facilitate connecting attachments. When working with pallet forks, the fork tips are visible to assist picking up pallets with ease. The video image is shown in the built-in display of the 6R Tractor.

The camera is factory-installed in the loader factory; the wiring harness is protected inside the boom. The camera angle can be adjusted if needed. It is possible that a different position of the camera is desired, such as showing the contents of a bucket or the side of a snow blade. For such unique desires, spare cable length is available to enable customized camera positions.

Benefits

- Fast connection of attachments

- No damage to pallets and goods loaded on forks and spears

- Possibility for customized camera position

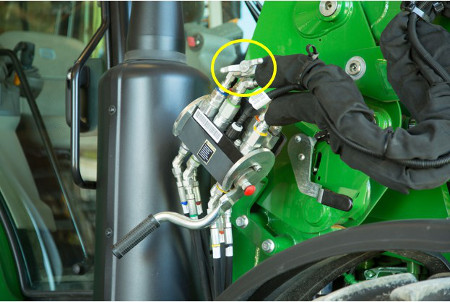

Single-point hydraulic connection on the 600R Loader

Single-point hydraulic connection on the 600R Loader

The R-Series Loaders feature a single-point hydraulic connection that saves the operator time when attaching or detaching the loader. This feature also incorporates the connection point for any electrical needs as well as the hydraulic lockout valve. With all hydraulic and electrical connections in one location, installation is quickly completed with the pull of a handle.

NOTE: Before disconnecting the hydraulic connection between the loader and the tractor, it is necessary to release the hydraulic pressure.

Single-point hydraulic connection (open)

Single-point hydraulic connection (open)

Single-point hydraulic connection (closed)

Single-point hydraulic connection (closed)

600R Loader with concealed oil lines

600R Loader with concealed oil lines

The R-Series Loaders are designed to route the oil lines and hydraulic lines through the boom arm and the torque tube. This internal routing ensures better protection of the lines from external damage and improves the overall appearance of the loader.

600R Loader (side view)

600R Loader (side view)

600R Loader (angle view)

600R Loader (angle view)

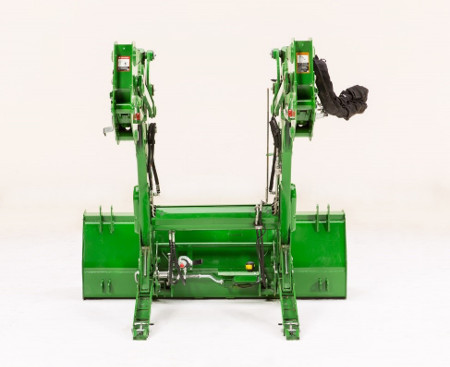

Rear view of 600R Loader

Rear view of 600R Loader

R-Series Loaders are even easier to attach and detach due to the automatic mast latch system. This feature provides efficiency to operations that require frequent loader parking. The automatic mast latch system is a mechanical lever that allows operators to remove or attach the loader with one trip out of the cab. The ease and convenience provided by the automatic mast latch system provides improvement to operation uptime.

Automatic mast latch lever

Automatic mast latch lever

Visual lock/unlock indicator

Visual lock/unlock indicator

Hydraulic shut-off valve on R-Series Loader

Hydraulic shut-off valve on R-Series Loader

The R-Series Loaders come equipped with a hydraulic shut-off valve to improve serviceability. When conducting brief service to the loader, close the hydraulic shut-off valve to ensure the loader does not move while operating under the equipment. This feature promotes a safe way to conduct brief maintenance without having to use support stands or removing the loader completely.

600R Loader working with 6120M Tractor

600R Loader working with 6120M Tractor

The MSL R-Series Loaders utilize a false rod cylinder to improve bucket performance. This bucket cylinder is designed with a smaller displacement of oil required on the head end of the cylinder, which allows the cylinder to function more quickly, decreasing operation cycle time. With the false rod cylinder design, loader applications can work more quickly and efficiently.

False rod cylinders on 600R Loader

False rod cylinders on 600R Loader

Specifications

Compare the specifications of up to 4 models

| Key Specs | 660r-loader Current Model |

|---|---|

| Maximum lift height (A) | 4495 mm 177 in. |

| Lift capacity at full height | Measured at pivot (U) 2301 kg 5073 lb |

| Boom breakout force | Measured at pivot (Y) 3235 kgf 7132 lbf |

| Bucket rollback force capacity | At ground-level line (ZZ) 4492 kgf 9903 lbf |

| Clearance at full height - bucket dumped (C) | 3481 mm 137 in. |

| Dump angle, degrees (E) | 60 degree (angle) |

| Rollback angle, degrees (G) | 48 degree (angle) |

| Tractor | |

| Model | 6145R/M, 6155R/M |

| Front tire | 540/65R30 |

| Rear tire | 650/65R42 |

| Front axle configuration | MFWD |

| Wheelbase | 2765 mm 108.9 in. |

| Pump capacity | 114 L/min 30.1 gpm |

| Rated pressure | 200 bar 2900 psi |

| Loader | |

| Base weight | 1674.3 kg |

| Leveling configuration | Mechanical Self Leveling (MSL) |

| Bucket used | Heavy-duty grapple 2450 mm Heavy-duty grapple 96 in. |

| Bucket weight | 375 kg 826 lb |

| Lift capacity at full height | Measured at pivot (U) 2301 kg 5073 lb Measured at 800 mm ahead of pivot (V) 2301 kg 5073 lb |

| Lift capacity at 59 in. (1500 mm) | Measured at pivot (W) 2814 kg 6204 lb Measured at 800 mm ahead of pivot (X) 2645 kg 5831 lb |

| Boom breakout force | Measured at pivot (Y) 3235 kgf 7132 lbf Measured at 800 mm ahead of pivot (Z) 2822 kgf 6221 lbf |

| Bucket rollback force capacity | At maximum height (VV) 2916 kgf 6429 lbf At 59-in. (1500-mm) lift height (XX) 4587 kgf 10113 lbf At ground-level line (ZZ) 4492 kgf 9903 lbf |

| Dimensions | Maximum lift height (A) 4495 mm 177 in. At full height - bucket level(B) 4255 mm 168 in. At full height - bucket dumped (C) 3481 mm 137 in. |

| Overall length (I+F), ft (m) | 5.6 m 18.4 ft |

| Digging depth (H) | 81 mm 3 in. |

| Reach | At maximum height (D) 1038 mm 41 in. At ground level - bucket level (F) 2848 mm 112 in. |

| Bucket angle | Dump angle, degrees (E) 60 degree (angle) Rollback angle, degrees (G) 48 degree (angle) Dump angle, ground 118 degree (angle) |

| Cycle times | Loader raise, seconds 3.91 seconds Loader lower, seconds 2.7 seconds Bucket dump, seconds 1.81 seconds Bucket rollback, seconds 1.81 seconds |