Features

Specifications

Accessories and Attachments

Ag Management Solutions

Beacon Lighting

The rotary beacon light is installed to meet requirements in commercial or governmental applications. The rotating, high-intensity light rests securely within an amber-colored safety lens. Both the light and lens are replaceable if damaged.

The rotary beacon light features a fully adjustable, double-clamp design that provides a more rigid vertical support stem.

The rotary beacon light is installed to meet requirements in commercial or governmental applications. The rotating, high-intensity light rests securely within an amber-colored safety lens. Both the light and lens are replaceable if damaged.

The rotary beacon light features a fully adjustable, double-clamp design that provides a more rigid vertical support stem.

Cab Equipment

Right-hand window wiper

Right-hand window wiperOptional right-hand window wiper with washer fluid is available on standard and premium cabs. This option allows the operator to clean the window in dusty conditions from the comfort of the cab. The windshield wiper fluid tank is located on the operator platform near the front of the cab.

Cab Operator's Station

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

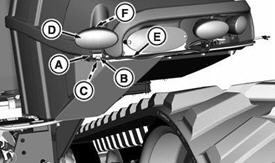

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mountRAM is a trademark of National Products Inc.

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mountRAM is a trademark of National Products Inc.

A favorite worldwide, the RAM self-leveling cup holder is now available as a kit - designed specifically for Deere equipment. It is easily installed to keep your favorite beverage upright even in the roughest terrain. The perfect accessory for any cab that has 10-mm mounting bosses.

Self-leveling cup holder John Deere branded beverage insulator included

Self-leveling cup holder John Deere branded beverage insulator included

The new cup holder features a unique self-leveling design. This pivoting design allows easy adjustment for the holder while offsetting motion of the vehicle when moving.

Features and applications:

- Self-leveling action reduces spills

- Durable design for rough environments

- Easy adjustable mounting for ideal placement

- Includes John Deere branded beverage insulator

- Compatible with most monitor brackets and all 10-mm threaded bosses

The producer can utilize various integrated technologies during sprayer operation and the following attachments allow them to properly fit, display, and charge these accessories:

- BRE10015 — Cell phone mount

- BRE10255 — Tablet mount

- RE343680 — Accessory mounting bracket

Commandview Iii Cab

This optional cross-gate joystick replaces fingertip paddle pots for control of selective control valves (SCVs) and allows for programmable hydraulic functionality according to operator preference.

Drawbar And Trailer Hitch

Electrical Equipment

Battery disconnect installed

Battery disconnect installedAvailable as either a factory- or field-installed attachment, the battery disconnect switch is used to disconnect the batteries in preparation for 20-day to 90-day storage periods. The switch cuts the power to the entire tractor to aid in maintaining battery life.

An indicator light allows for safe and proper disconnect. The light will flash until it is safe to disconnect. This allows the diesel exhaust fluid (DEF) tank and lines to purge. (Final Tier 4 has an indicator light and Interim Tier 4 has no indicator light.)

Cummins is a trademark of Cummins Incorporated.

ISO 11783 location in R-Series Tractor cab

ISO 11783 location in R-Series Tractor cab RE322780 ISO cab implement CAN bus adapter

RE322780 ISO cab implement CAN bus adapterThe ISO cab implement controller area network (CAN) bus adapter is available to connect any ISO compliant implement or device to an 8R, 8RT, 9R, 9RT, 9RX (including Scraper Special) Series Tractor. These connectors are commonly used for planter frame control boxes.

Refer to the operator's manual, sections 16 (CommandCenter™) and 25 (Operator Station), for additional information on ISO implements.

NOTE: If the harness is not in use, unplug it from the ISO 11783 location or plug the 4-pin connectors together on the harness. If neither of these are done, implement CAN communication errors will occur.

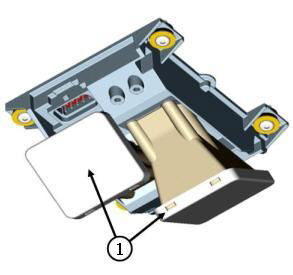

Dual-beam radar emission horns

Dual-beam radar emission horns  Dual-beam radar (tracks tractor shown)

Dual-beam radar (tracks tractor shown) Shield for dual radar beam

Shield for dual radar beamIn today’s agricultural environment, accuracy and precision are more important than ever. For something as basic as ground speed, operators need key information for precise control of various implements and the tractor. To support these needs, tractors can be ordered with a dual-beam radar unit as a factory- or field-installed option.

There are several key features that have changed from previous designs.

First, there are two horns for exit of the radio beam. This dual-beam design assures a powerful and accurate signal that will cut through interference that at times makes single-beam units inaccurate. (See 1 in the image above for beam locations.) Dual-beam output makes radar less susceptible to hard surface or tall/wavy grass interference.

Accuracy is aided by a heavy-gauge mounting bracket and rubber isolators that reduce chances that vibration can affect the radio signal.

Dual-beam radar has a fast update rate. When the tractor comes to a stop, accelerates, or varies speed, the indicated ground speed on the tractor display will closely match the actual ground speed. This is important for implements that use radar speed to control operation such as planters, seeders, fertilizer applicators, and sprayers.

In addition, the dual-beam radar does not require calibration to assure accuracy. Its self-calibrating ability is sure to save setup time by elimination of a special procedure that was required in the past.

The radar true ground speed sensor activates the following CommandCenterTM display or performance monitor readouts:

- Percent slip

- Hitch slip command (if equipped)

Radar usage improves the accuracy of the following CommandCenter or performance monitor functions:

- Area covered

- Area/hour

- Distance and ground speed

Dual-beam units are compatible with controller area network (CAN) bus and International Organization for Standardization (ISO) bus electrical systems.

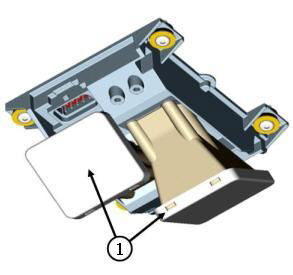

Dual-beam radar emission horns

Dual-beam radar emission horns  Dual-beam radar (tracks tractor shown)

Dual-beam radar (tracks tractor shown) Shield for dual radar beam

Shield for dual radar beamIn today’s agricultural environment, accuracy and precision are more important than ever. For something as basic as ground speed, operators need key information for precise control of various implements and the tractor. To support these needs, tractors can be ordered with a dual-beam radar unit as a factory- or field-installed option.

There are several key features that have changed from previous designs.

First, there are two horns for exit of the radio beam. This dual-beam design assures a powerful and accurate signal that will cut through interference that at times makes single-beam units inaccurate. (See 1 in the image above for beam locations.) Dual-beam output makes radar less susceptible to hard surface or tall/wavy grass interference.

Accuracy is aided by a heavy-gauge mounting bracket and rubber isolators that reduce chances that vibration can affect the radio signal.

Dual-beam radar has a fast update rate. When the tractor comes to a stop, accelerates, or varies speed, the indicated ground speed on the tractor display will closely match the actual ground speed. This is important for implements that use radar speed to control operation such as planters, seeders, fertilizer applicators, and sprayers.

In addition, the dual-beam radar does not require calibration to assure accuracy. Its self-calibrating ability is sure to save setup time by elimination of a special procedure that was required in the past.

The radar true ground speed sensor activates the following CommandCenterTM display or performance monitor readouts:

- Percent slip

- Hitch slip command (if equipped)

Radar usage improves the accuracy of the following CommandCenter or performance monitor functions:

- Area covered

- Area/hour

- Distance and ground speed

Dual-beam units are compatible with controller area network (CAN) bus and International Organization for Standardization (ISO) bus electrical systems.

Engine

Attachment, Fuel Water Separator, 13.5 L Engine - BRE10206

7030 Series Large-Frame Tractor shown

7030 Series Large-Frame Tractor shownThe severe-duty water separator factory-installed option or field-installed kit is available for locations where fuel quality can at times be in question. This kit will extend service intervals and help protect the tractor fuel system from damage if the fuel contains more water than the base filtering equipment can handle on a continual basis.

The 60 micron constructed of stainless-steel filter element must be backflushed whenever the bowl is half full of water. The filter can be backflushed up to five times before the filter must be removed and cleaned. Filter element must be replaced when light is no longer visible through the filter. The replacement interval will vary depending on fuel quality.

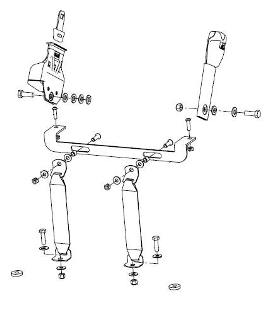

Front Axle

The following tractor combinations are either recommended or required to install front axle and rear support kits (see chart) based off of machine configurations.

Front frame and axle support kits

Front frame and axle support kits provide additional support to the front frame and axle joint when the tractor is used in applications that put high torque and high vertical loads on the front end of the machine. This includes front-mounted spray tanks.

9RX Series Tractors

A front frame support kit (BRE10401) is required on all 9RX Series Tractors with front-mounted spray tanks. This kit enables operators to utilize the 9RX Tractors for supplemental crop nutrition application or for utilizing a 3-point hitch mounted sprayer. The front frame supports are standard on all 9RX Scraper Tractors.

9000 and 9R Series Wheel Tractors

Tractor models | With HydraCushion™ suspension | With front ballast | With front-mounted spray tanks |

9370R-9470R | --- | BRE10198 required | BRE10198 required |

9520R-9620R | BRE10145 required | --- | --- |

Previous models |

|

|

|

9R Series | --- | RE341567 required | RE341567 required |

9030 Series | --- | RE267769 recommended | RE267769 required |

9000 Series/9020 Series | --- | RE213187 recommended | RE213187 required |

For 9460R-9560R Scraper Tractors, please order RE341567 when using front ballast or front-mounted spray tanks. No front support is needed on 9470R-9620R Scraper Tractors.

NOTE: All 9000 and 9R Series Tractors require additional front axle and frame support when used with front-mounted dozer blades. This support is in place of the front axle support and is supplied by the dozer blade manufacturer. Please contact the dozer blade manufacturer for additional information.

Rear axle support kits

The rear axle support provides additional support to the rear frame and axle joint when the tractor is used in applications that put high torque and high vertical loads on the back end of the machine.

9RX Series Tractors

The rear axle support (code 8042) is required when a hitch is ordered on any 9RX Series Tractors; it is optional without a hitch. Rear axle supports are standard on all 9RX Series Scraper Tractors.

9000 and 9R Series Wheel Tractors

Tractor models | High vertical load or heavy draft applications | With order code 8000 (heavy-duty frame) | With 6940-kg (15,000-lb) hitch option, code 4050 or 4051 | With 9072-kg (20,000-lb) hitch option, code 4052 or 4053 |

9370R-9470R | RE268085 recommended | RE268085 recommended | RE268085 recommended | RE268085 required |

9520R-9620R* | --- | --- | --- | --- |

Previous models |

|

|

|

|

9R Series model year 2012 to model year 2014 | RE268085 recommended | RE268085 recommended | RE268085 recommended | RE268085 required |

9030 Series | RE268085 recommended | RE268085 recommended | RE268085 recommended | --- |

*The rear axle support is not available on 9520R – 9620R Tractors because the double reduction axle design already provides this level of support.

Mounting of dozer blades:

The mounting of dozer blades is approved on 9R Series and 9RX Series Tractors with 76.2-cm and 91.4-cm (30-in. and 36-in.) tracks. The mounting of dozer blades is not approved on 9RT Series Tractors and 9RX Series Tractors with 45.7-cm and 61-cm (18-in. and 24-in.) tracks.

- For all 9R Series and 9RX Series Tractors with 76.2-cm and 91.4-cm (30-in. and 36-in.) tracks, additional frame supports supplied by the dozer manufacturer are required.

- Follow manufacturer guidelines for mounting dozer blade components to the frame of the tractor.

NOTE: 9R Series and 9RX Series Tractors with 76.2-cm and 91.4-cm (30-in. and 36-in.) tracks are approved for typical agricultural applications, such as packing silage, pushing snow, and non-commercial dirt moving blade work. 9RX Series Tractors with 45.7-cm and 61-cm (18-in. and 24-in.) tracks are not approved for front blade work.

Hydraulic Selective Control Valves (Scvs)

9RT rear hydraulics

9RT rear hydraulics CommandARM™ SCV controls

CommandARM™ SCV controlsHigh-flow fifth and sixth SCVs provide additional hydraulic flow for use with triple scraper pans.

Lighting

A rear fender rear facing work light is available for your tractor. The kit comes with mounting hardware and a harness which directly connects to your tractors existing harness.

This mounting location allows for illumination of your hitch and drawbar area to aid on making connections to your implement with natural lighting conditions are poor.

Mirrors

John Deere CommandView™ III cab offers several options for outside mirrors to increase rear visibility to assist in getting the view needed of variable-width implements, wagons, or carts. The wide-angle mirror options provide excellent overall rear visibility and are easily adjusted and telescope to maintain visibility for a variety of implements.

7R and 8R Series Tractor mirror options:

- Manually adjustable, single pane

- Wide angle, heated, electrically adjustable top pane, manual telescoping

- Wide angle, heated, electrically adjustable top pane, electrically telescoping

8RT Series Tractor mirror options:

- Manually adjustable, single pane

- Wide angle, heated, electrically adjustable top pane, electrically telescoping

9R and 9RX Series Tractor mirror options:

- Manually adjustable, single pane

- Wide angle, heated, electrically adjustable top pane, manual telescoping

- Wide angle, heated, electrically adjustable top pane, electrically telescoping

9RT Series Tractor mirror options:

- Manually adjustable, single pane

- Wide angle, heated, electrically adjustable top pane, electrically telescoping

Field-installed kits are also available to convert a manual mirror to an electrically adjustable mirror. See the attachment section for further information.

NOTE: Left-hand electrically telescoping mirrors are not compatible with 8RT and 9RT Tractors.

Manually adjustable, single pane mirrors

Manually adjustable, single pane mirrors Wide-angle, heated, electrically adjustable top pane, manually telescoping mirrors

Wide-angle, heated, electrically adjustable top pane, manually telescoping mirrors Wide-angle, heated, electrically adjustable top pane, electrically telescoping mirrors

Wide-angle, heated, electrically adjustable top pane, electrically telescoping mirrors Wide-angle, heated top pane, electrically adjustable top pane, non-telescoping left-hand mirror for 8RT and 9RT Series Tractors

Wide-angle, heated top pane, electrically adjustable top pane, non-telescoping left-hand mirror for 8RT and 9RT Series Tractors

John Deere CommandView™ III cab offers several options for outside mirrors to increase rear visibility to assist in getting the view needed of variable-width implements, wagons, or carts. The wide-angle mirror options provide excellent overall rear visibility and are easily adjusted and telescope to maintain visibility for a variety of implements.

7R and 8R Series Tractor mirror options:

- Manually adjustable, single pane

- Wide angle, heated, electrically adjustable top pane, manual telescoping

- Wide angle, heated, electrically adjustable top pane, electrically telescoping

8RT Series Tractor mirror options:

- Manually adjustable, single pane

- Wide angle, heated, electrically adjustable top pane, electrically telescoping

9R and 9RX Series Tractor mirror options:

- Manually adjustable, single pane

- Wide angle, heated, electrically adjustable top pane, manual telescoping

- Wide angle, heated, electrically adjustable top pane, electrically telescoping

9RT Series Tractor mirror options:

- Manually adjustable, single pane

- Wide angle, heated, electrically adjustable top pane, electrically telescoping

Field-installed kits are also available to convert a manual mirror to an electrically adjustable mirror. See the attachment section for further information.

NOTE: Left-hand electrically telescoping mirrors are not compatible with 8RT and 9RT Tractors.

Manually adjustable, single pane mirrors

Manually adjustable, single pane mirrors Wide-angle, heated, electrically adjustable top pane, manually telescoping mirrors

Wide-angle, heated, electrically adjustable top pane, manually telescoping mirrors Wide-angle, heated, electrically adjustable top pane, electrically telescoping mirrors

Wide-angle, heated, electrically adjustable top pane, electrically telescoping mirrors Wide-angle, heated top pane, electrically adjustable top pane, non-telescoping left-hand mirror for 8RT and 9RT Series Tractors

Wide-angle, heated top pane, electrically adjustable top pane, non-telescoping left-hand mirror for 8RT and 9RT Series TractorsMiscellaneous

AutoLoad is exclusive to John Deere and is a major innovation in the earthmoving industry. It allows novice and experienced operators to be more consistent and productive while operating John Deere tractors and scrapers. With the touch of a button, operators maximize productivity and efficiency even if they have never operated tractors and scrapers.

The system includes a draft sensor on the drawbar, radar for measuring wheel slip, position sensors on the scrapers, AutoLoad CommandCenter™ console, and a controller that analyzes the inputs from all sensors and controls the scraper operation during the loading cycle, providing consistent productivity.

- Compatible with John Deere ejector and carry-all scrapers

- Single, double, or triple scraper pans

- Will retrofit to any John Deere scraper, model year 2004 and newer

Mounting brackets are available to mount a standard ABC extinguisher to your tractor. The bracket mounts to the entrance platform at the top of the entrance/egress steps on 9R series tractors.

This location allows quick access to the extinguisher near the cab door, should it ever be needed.

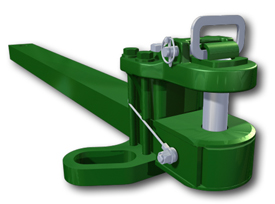

Quick Attach Drawbar for 9RX Scraper Special Tractors with short drawbar supports - BXT10046

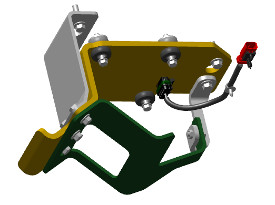

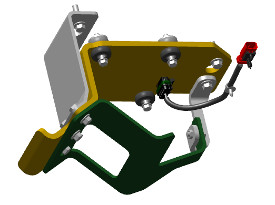

Hydraulic hose support

Hydraulic hose support

This field-installed option reduces stress on the couplers by providing support to the heavy hydraulic hoses used in scraper application. The hydraulic hose support attaches to the back of the tractor next to the drawbar and is available on all 9R, 9RT and 9RX Scraper Tractors.

Custom key door locks

Custom key door lock kit

Custom key door lock kitField-installed kit (AL71345) allows for a door handle to be installed that has a key different from the tractor ignition key.

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mountRAM is a trademark of National Products Inc.

Operator's Station

Accessories mounting bracket

Accessories mounting bracket Tray kit

Tray kitThe accessories bracket is available for mounting monitors, phones, radios, and other accessories in one convenient location.

The bracket connects in the existing holes inside the cab.

This kit provides antenna mount, radio mounting plate, and wiring for a business band radio.

Backup alarm on a 9R Series Tractor

Backup alarm on a 9R Series Tractor

To better accommodate governmental or commercial sales, a back-up alarm is available as a factory- or field-installed attachment on select models. An alarm sounds whenever the transmission is placed in reverse. The alarm provides a high level of warning that the tractor is changing direction.

A backup alarm is base equipment on 9R and 9RT Scraper Special Series Tractors.

Cornerpost Display Bracket - PF90385

The floor insulation kit can reduce cab heat generated by transmission and hydraulic oil temperatures below the cab floor. It can reduce the overall cab temperature, as it works as a thermal barrier. The product comes in a large sheet, which is easily cut to fit the contours of the cab floor.

The kit is large enough to fit the floor pan design of 6 through 9 Series Tractor cabs.

Radio

Premium Radio Package with XM Radio - BRE10196

This kit replaces the rear upholstery behind the operator seat with an additional panel containing a grille screen and base speaker. It allows the tractor to reproduce a deeper range of base tones with seamless installation. The clean look and powerful sound adds a level of comfort and enjoyment for long days in the cab.

Radio

RadioJohn Deere radio packages provide powerful performance with standard four-speaker systems. The standard radio package features easy-to-use operator controls located on the CommandCenter™ display and at the radio faceplate. AM/FM and weatherband tuner allows operators to stay tuned to their favorite radio stations and keep current with ever-changing weather patterns. An auxiliary input for connecting an external media source is conveniently located on the right-side console.

The premium radio package adds to these great features with Bluetooth® to connect with compatible media devices and a USB input for connecting external media sources. A subwoofer is also available in this package to increase the operator experience within the cab.

Both radio packages help create a comfortable operator environment for long hours in the cab.

Standard radio package

- AM/FM and weatherband tuner (NOAA broadcast channels)

- External antenna

- Remote controls through the CommandARM™ controls (volume, mute, channel up/down)

- CommandCenter display with station selection, volume level, and station presets

- Auxiliary input (3.5 mm [0.14 in.]) on right-side console

- Four coaxial speakers

Premium radio package*

- AM/FM, weatherband (NOAA broadcast channels), and worldwide premium tuner

- External antenna

- Remote controls through CommandARM (volume, mute, channel up/down)

- CommandCenter display with station selection, volume level, and station presets

- Universal serial bus (USB) input

- Auxiliary input on right-side console

- Bluetooth capable with microphone (allows phone and streaming audio)

- Four coaxial speakers

- Subwoofer

*XM Satellite functionality for premium radio needs to be upgraded by purchasing the XM antenna, XM receiver, brackets, and wiring harnesses via a kit from your local John Deere dealer.

Radio controls

Radio controlsBosch is a trademark of Robert Bosch GmBH. Bluetooth is a trademark of Bluetooth SIG Incorporated. XM is a trademark of XM Satellite Radio Incorporated. Delco is a trademark of General Motors LLC.

Rear Hitch

Conversion kit

Conversion kitA Category 5 to Category 4 drawbar conversion kit is available for operators who have Category 4 implements that cannot be converted to Category 5.

The preferred method when operating high-horsepower tractors is to convert implements to Category 5.

For additional implement information, please reference the planting and seeding or the tillage information.

Seat

Seat belt for 8R Series Tractors

Seat belt for 8R Series TractorsThe 3-in. field-installed seat belt kit is designed for use with the 8R and 8RT Series Tractor operator seats. The seat belt kit is offered to meet regulations that require a seat belt anchorage force similar to the SAE J386 (including previous versions up to 22.2 kN anchorage strength), IOS 6683, and OSHA requirements (29CFR1926.602) for earthmoving operations and non-agricultural tractor operations.

NOTE: John Deere recommends reviewing the seat belt kit performance capabilities to ensure compliance with local, state, regional, and national requirements.

Tracks

Inner drive sprocket mud scraper (wide track shown)

Inner drive sprocket mud scraper (wide track shown) Idler debris shield (wide track shown)

Idler debris shield (wide track shown)

The 9RX Series undercarriage includes mud scrapers on the outer circumference of the drive sprocket as standard equipment.

There are two additional self-cleaning kits available as an attachment.

The inner drive-sprocket mud scraper continuously removes bulk debris from the sprocket hub and discards it to the outside of the track assembly while the tractor is in forward motion.

The idler debris shield is attached to the rearward idler and continuously removes bulk debris from the idler as well as protects the track-tensioning cylinders from light impact and debris buildup while the tractor is in forward motion.

Both kits are designed to significantly reduce mud, sand, rocks, and other potential buildup in the track assembly, while also increasing track belt life by discarding debris directly to the ground rather than on the track surface. Kits are available in two sizes depending on wide- or narrow-track undercarriage.

Inner drive sprocket mud scraper (wide track shown)

Inner drive sprocket mud scraper (wide track shown) Idler debris shield (wide track shown)

Idler debris shield (wide track shown)

The 9RX Series undercarriage includes mud scrapers on the outer circumference of the drive sprocket as standard equipment.

There are two additional self-cleaning kits available as an attachment.

The inner drive-sprocket mud scraper continuously removes bulk debris from the sprocket hub and discards it to the outside of the track assembly while the tractor is in forward motion.

The idler debris shield is attached to the rearward idler and continuously removes bulk debris from the idler as well as protects the track-tensioning cylinders from light impact and debris buildup while the tractor is in forward motion.

Both kits are designed to significantly reduce mud, sand, rocks, and other potential buildup in the track assembly, while also increasing track belt life by discarding debris directly to the ground rather than on the track surface. Kits are available in two sizes depending on wide- or narrow-track undercarriage.

Inner drive sprocket mud scraper (wide track shown)

Inner drive sprocket mud scraper (wide track shown) Idler debris shield (wide track shown)

Idler debris shield (wide track shown)

The 9RX Series undercarriage includes mud scrapers on the outer circumference of the drive sprocket as standard equipment.

There are two additional self-cleaning kits available as an attachment.

The inner drive-sprocket mud scraper continuously removes bulk debris from the sprocket hub and discards it to the outside of the track assembly while the tractor is in forward motion.

The idler debris shield is attached to the rearward idler and continuously removes bulk debris from the idler as well as protects the track-tensioning cylinders from light impact and debris buildup while the tractor is in forward motion.

Both kits are designed to significantly reduce mud, sand, rocks, and other potential buildup in the track assembly, while also increasing track belt life by discarding debris directly to the ground rather than on the track surface. Kits are available in two sizes depending on wide- or narrow-track undercarriage.